جدول المحتويات

حبر البلاستيسول عالي الكثافة: ثورة في طباعة الشاشة

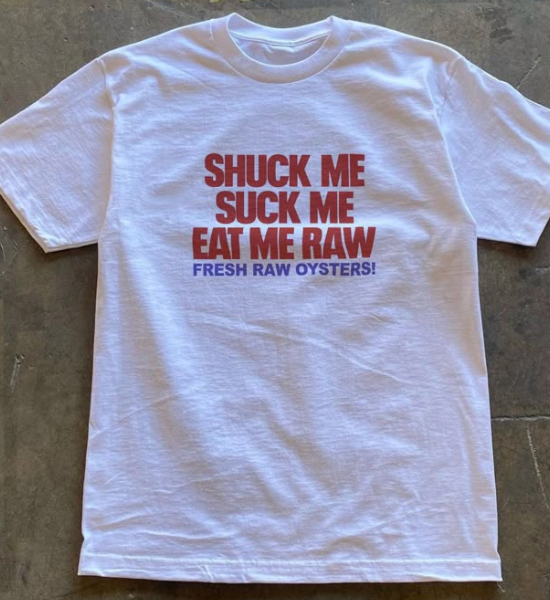

حبر بلاستيسول عالي الكثافة يُغيّر عالم طباعة الشاشة. هذا الحبر السميك والقوي يُتيح لك صنع تصاميم ثلاثية الأبعاد, ألوان زاهيةومطبوعات تدوم لسنوات. لنكتشف كيف تعمل ولماذا عليك تجربتها!

ما هو حبر البلاستيسول عالي الكثافة؟

حبر بلاستيسول عالي الكثافة هو حبر خاص يستخدم في طباعة الشاشة. وهي مصنوعة من:

- راتنج البولي فينيل كلوريد (نوع من البلاستيك).

- الملدنات (الزيوت التي تجعل الحبر ناعمًا).

- المضافات (لجعلها سميكة وقوية).

عند تسخينه، يتصلب هذا الحبر إلى تصميم مرتفع يمكنك الشعور بها بأصابعك. علامات تجارية مثل ويلفليكس كوانتم اتش دي و سلسلة FN Ink Xenon اصنع إصدارات شعبية من هذا الحبر.

أهم 5 أسباب لاستخدام حبر البلاستيسول عالي الكثافة

- نسيج ثلاثي الأبعاد:يصنع التصاميم جحظ مثل الملصق.

- ألوان زاهية:يبقى نابضًا بالحياة قمصان سوداء والأقمشة الداكنة.

- المتانة:لن يتشقق أو يتلاشى أو يتقشر بعد الغسيل.

- يعمل على العديد من المواد:استخدمه على القطن والبوليستر والحقائب والأكواب والمزيد.

- فعالة من حيث التكلفة:يوفر المال لأن المطبوعات تدوم لفترة أطول.

كيفية استخدام حبر البلاستيسول عالي الكثافة

الأدوات التي تحتاجها:

- أ شاشة مع عدد الشبكات 110-160.

- أ ممسحة مطاطية (لدفع الحبر عبر الشاشة).

- أ مجفف فلاش (لتسخين الحبر وتصلبه).

دليل خطوة بخطوة:

- إعداد الشاشة:

- استخدم مستحلبًا سميكًا.

- حافظ على الشاشة أعلى قليلاً من القماش.

- اطبع التصميم:

- ضع طبقة الحبر 2-3 مرات.

- استخدمي مجفف الشعر السريع بين الطبقات.

- علاج الحبر:

- الحرارة في 320 درجة فهرنهايت ل 45-60 ثانية.

نصيحة احترافية:آلات مثل معدات الطباعة M&R إعطاء أفضل النتائج.

البلاستيسول عالي الكثافة مقابل الأحبار الأخرى

| نوع الحبر | الأفضل لـ | الأسوأ بالنسبة لـ |

|---|---|---|

| بلاستيسول عالي الكثافة | نسيج ثلاثي الأبعاد وشعارات جريئة | مشاريع صديقة للبيئة |

| حبر مائي | تصاميم ناعمة وخفيفة | الأقمشة الداكنة |

| حبر التفريغ | مظهر عتيق باهت | مواد البوليستر |

مثال: يختار بلاستيسول عالي الكثافة للقبعات أو القمصان مع شعارات بارزة.

إصلاح المشاكل الشائعة

| مشكلة | حل |

|---|---|

| تكسير | علاج لمدة أطول عند 320 درجة فهرنهايت |

| نزيف الألوان | يضيف عوامل النزيف المنخفض |

| الحبر لا يلتصق | نظف القماش أولا |

أداة للتجربة: روتلاند إيفو تساعد الإضافات على منع النزيف.

أحبار عالية الكثافة صديقة للبيئة

الأحبار الحديثة أكثر أمانًا للناس والكوكب:

- خالي من الفثالات الخيارات (مثل ماجنا كولورز).

- يتبع معيار أويكو تكس 100 (آمن للتلامس مع الجلد).

نصيحة:قم بإعادة تدوير الشاشات وحاويات الحبر لتقليل النفايات.

أمثلة من العالم الحقيقي

- نايكي:يستخدم حبرًا ثلاثي الأبعاد على القمصان الرياضية للحصول على الملمس.

- أديداس:يصنع قمصانًا بإصدار محدود مع شعارات بارزة.

- الفنانون:إنشاء معرض فني مع التصاميم اللمسية.

حدث:انظر الأحبار الجديدة في معرض الطباعة المتحدة.

الاتجاهات المستقبلية

- الأحبار الهجينة:اخلط البلاستيسول مع الأحبار القائمة على الماء للحصول على النعومة والمتانة.

- الأدوات الرقمية:برامج مثل أكيوريب يساعد في تصميم أنماط دقيقة.

هل يجب عليك تجربة حبر البلاستيسول عالي الكثافة؟

نعم إذا كنت تريد:

- التصاميم التي دافع عن كرامته.

- المطبوعات التي بقيت على قيد الحياة أكثر من 100 غسلة.

ابدأ صغيرًا:قم باختباره على عينة من القماش أولاً!

الأسئلة الشائعة

هل يمكنني استخدام هذا الحبر على البوليستر؟

نعم! أضف عامل نزيف منخفض لمنع انتشار الألوان.

هل يمكنني طباعة التفاصيل الدقيقة؟

استخدم شاشة شبكية 160+ للخطوط الرفيعة والنصوص الصغيرة.

كيفية تقليل النفايات؟

قم بقياس الحبر بعناية وإعادة استخدام الشاشات.