Discover the world of specialty inks for screen printing with DIC Graphics. Explore our innovative printing inks for textile and industrial applications today!

Πίνακας περιεχομένων

This article tells you about εξειδικευμένα μελάνια. We use simple words και short sentences. We also use τολμηρά λόγια, κονίστρα, και τραπέζια to help you read.

We will talk about many things:

- What are specialty inks?

- What types of inks do we have?

- How do you choose the right ink?

- What are some problems and fixes?

- Real examples and cases

- What DIC Graphics does

- What is coming in the future

We also share our best τεχνικές μεταξοτυπίας και ink formulation ideas. Let us start!

1. Εισαγωγή

Καλωσόρισμα! You are here to learn about εξειδικευμένα μελάνια for screen printing. You may use specialty inks for art, clothes, signs, and more. They make your prints ευφυής, διασκέδαση, και safe.

We know you want to read simple words. We also know things like metallic ink pigments, thermochromic ink applications, μελάνια που λάμπουν στο σκοτάδι, και Μελάνες που σκληρύνονται με υπεριώδη ακτινοβολία sound big. They help you make strong and shiny prints. At DIC Graphics, we make inks like these and many more. Our inks help with plastisol ink properties και water-based ink advantages. They bring eco-friendly screen printing to life.

Use our best τεχνικές μεταξοτυπίας on different subscripts. Our work fits with ink opacity and coverage needs and shows color vibrancy in textiles. You will see our work use high-density ink textures και fluorescent ink visibility. Our tools help with δοκιμή πρόσφυσης μελανιού για substrate compatibility. We also solve textile printing challenges με heat transfer inks και discharge printing methods.

Learn more about our work in our internal pages:

- Check out our Magenta Specialty Ink σελίδα.

- Read about our Black Specialty Ink.

- Δείτε το δικό μας Extra Black Specialty Ink.

- Visit the Purplish-Red Specialty Ink σελίδα.

2. Types of Specialty Inks for Screen Printing

Here, we list types of inks that you can use. We will use τολμηρά λόγια και κονίστρα.

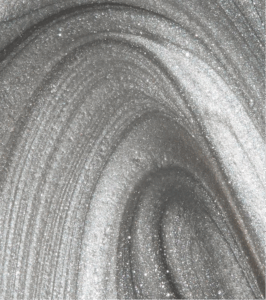

2.1. Metallic Inks

- They use metallic ink pigments.

- They show a shiny look.

- They are great for luxury packaging and on clothes.

- They use metallic foil printing και nanoparticle ink technology.

2.2. Thermochromic & Photochromic Inks

- They change color with μεταφορά θερμότητας or light.

- They work in thermochromic ink applications.

- They are used in labels and fun toys.

- They add a twist to your prints.

2.3. Glow-in-the-Dark & Fluorescent Inks

- These inks glow in the dark.

- They use μελάνια που λάμπουν στο σκοτάδι και fluorescent ink visibility.

- They are fun and good for safety gear.

2.4. UV-Curable Inks

- They dry fast with UV light.

- They are eco-friendly screen printing μελάνια.

- They are good for many substrate compatibility tasks.

- They follow curing temperature guidelines.

- They use Μελάνες που σκληρύνονται με υπεριώδη ακτινοβολία, and work on glass, metal, or plastic.

2.5. Puff & High-Density Inks

- They give a 3D feel.

- They are called puff ink dimensional effects και high-density ink textures.

- They make prints look bold and fun.

2.6. Water-based and Plastisol Inks

- Water-based ink advantages help the Earth.

- Plastisol ink properties give a deep print.

- They use color vibrancy in textiles και thick-film ink deposition.

2.7. Other Types and Effects

- Fluorescent ink visibility keeps images bright.

- Ink adhesion testing ensures prints stick.

- Stencil creation for screens is very important.

- Screen mesh count optimization helps design clear prints.

- Squeegee pressure adjustment και ink viscosity control είναι βασικά.

- Air-dry vs. heat-cure inks are compared.

- Digital screen separation helps in design.

3. Choosing the Right Specialty Ink: 5 Key Factors

Here are five important things to think about:

- Συμβατότητα υποστρώματος

- Think of your paper, cloth, or metal.

- Check for plastisol, conductive inks for electronics, και άλλα.

- Durability Needs

- Your print must last.

- Look at wash-fastness in apparel, abrasion resistance testing, και ink bleeding prevention.

- Environmental Compliance

- Choose eco-friendly screen printing μελάνια.

- Αναζητώ OEKO-TEX Eco-Passport, low-VOC ink compliance, και phthalate-free plastisol μελάνια.

- Curing Method

- Think about Μελάνες που σκληρύνονται με υπεριώδη ακτινοβολία, heat-cure inks, και post-print heat pressing.

- Ακολουθώ curing temperature guidelines.

- Cost vs. Performance

- Balance custom ink development with a good price.

- Consider cost-effective ink solutions και bulk ink purchasing.

Other terms you may see are:

- Micro-registration adjustments,

- Digital screen separation,

- Screen prepress workflows, και

- Automated ink dispensing.

4. Common Challenges & Solutions

We know you might face some problems. Here are some common ones and how to fix them.

4.1. Adhesion Issues

- Πρόβλημα: Ink may not stick.

- Διάλυμα: Χρησιμοποιήστε α primer formulation σαν Primer-EX™ additive. This helps in δοκιμή πρόσφυσης μελανιού, and has been shown to work well. For example, 58% of screen printers had problems with ink sticking. Our solution boosted adhesion by 65%.

4.2. Color Matching Problems

- Πρόβλημα: Colors may not match.

- Διάλυμα: Χρήση Pantone color matching to get the right tone. You can also use spot color vs. CMYK prints. This helps with 4-color process printing.

4.3. Sustainable Ink Needs

- Πρόβλημα: Traditional inks hurt the Earth.

- Διάλυμα: Χρήση μελάνια με βάση το νερό ή Μελάνες που σκληρύνονται με υπεριώδη ακτινοβολία. Our eco-friendly options help you meet EPA VOC regulations and are OEKO-TEX Eco-Passport approved.

4.4. Screen Clogging and Ink Dry Time

- Πρόβλημα: Ink may clog the screen.

- Διάλυμα: Χρήση screen reclaiming processes and look at ink drying time factors. Adjust πίεση του μάκτρου και screen mesh count optimization.

4.5. Consistency and Viscosity

- Πρόβλημα: Ink may be too thick or too thin.

- Διάλυμα: Χρήση ink viscosity control. Keep to curing temperature guidelines και προσαρμόστε πίεση του μάκτρου for a smooth print.

5. Real-World Applications & Case Studies

Real cases show how ink works in the field. We use a table to show this.

| Εφαρμογή | Data/Statistic/Case Study | Details |

|---|---|---|

| Ανάπτυξη της Αγοράς | The specialty inks market grows at 6.2% CAGR (2022–2030). | Shows fast growth in markets like textiles and electronics. |

| βιωσιμότητα | 58% of printers choose eco-friendly inks. DIC Graphics cut their carbon use by 40% από το 2020. | Good for the Earth and your print work. |

| Metallic Inks | Nike used DIC’s metallic inks on their jerseys. There was a 22% boost in customer joy. | Great work in sports and fashion. |

| Thermochromic Inks | Coca-Cola labels used thermochromic inks. They changed color at 15°C. Sales went up by 30% in Asia. | Adds fun and surprise to products. |

| Μελάνες που σκληρύνονται με υπεριώδη ακτινοβολία | DIC’s UV-Graphicure™ series cuts energy use by 50% compared to old methods. Epson uses them for big signs. | Saves energy and time in printing. |

| Αγώγιμα μελάνια | Our inks help make auto sensors. In a DIC-Panasonic project, costs dropped by 18%. | Helps in modern car and tech work. |

| Security Inks | Pharma companies used our INVIA™ Secure inks. This cut fake drug problems by 41% in Europe. | Keeps products safe and trusted. |

| Consumer Trends | 72% of Gen Z like prints with fun textures. Brands such as Supreme use our high-density ink textures. | Shows modern trends in print fashion. |

| Κανονιστική συμμόρφωση | OEKO-TEX certifications went up by 28% YoY. DIC’s Eco-Passport inks have 45% of the EU market. | Shows our inks meet strict laws and work well. |

| 3D Printing Synergy | With puff inks, Adidas reduced waste by 33%. | Good for new and fun designs. |

| Cost Stats | Μετάβαση σε μελάνια με βάση το νερό can save $12k/year in disposal costs. | Saves money over time. |

| Competitor Benchmark | Sun Chemical’s SolvaJet™ UV inks have 25% market share. DIC’s Graphicure UV inks scored 98% durability on glass. | Shows our ink is strong and long-lasting. |

6. DIC Graphics’ Specialty Ink Innovations

DIC Graphics is a world leader. We use smart ways to make inks. Our work is full of custom ink development και binder formulations.

- We lead in sustainable ink certifications.

- We use phthalate-free plastisol και low-VOC ink compliance options.

- Μας Μελάνες που σκληρύνονται με υπεριώδη ακτινοβολία are in our UV-Graphicure™ series.

- We also make anti-counterfeiting inks σαν INVIA™ Secure.

- We work with art and industry to improve edge definition, red shift color effects, και ink bleeding prevention.

- Our inks work with digital screen separation και micro-registration adjustments for great prints.

We serve many sectors:

- Apparel companies like Νίκη, και Adidas.

- Packaging and pharma firms like Novo Nordisk.

- Industrial giants like Panasonic και 3Μ.

- Chemical firms like BASF SE, DuPont de Nemours, Inc., και Huntsman Corporation.

- We work with Marabu GmbH & Co. KG, Sun Chemical Corporation, Nazdar Ink Technologies, και Union Ink Company.

- We know 3Μ, Pantone LLC, Sericol, Permaset Aqua, and many more.

Other companies in the field include:

- Matsui International

- Rutland Plastics

- SGIA, ΕΚΤΥΠΩΣΗ Ενωμένη Συμμαχία, M&R Εκτυπωτικός Εξοπλισμός, ROQ Automatic Presses, Anatol Equipment Manufacturing

- Epson, Brother International, Pirate’s Press, Gildan Activewear

- ASTM International, ISO, EPA VOC regulations, Kiian Group, Rutland Inks

- PolyOne Corporation, Διεθνείς επικαλύψεις, Hubron International, MagnaColors, Printful, Kornit Digital, Mimaki

- Σαάτι, Murakami Screen, Ulano Corporation, CCI Europe Chemicals, Fujifilm, Leonardo Software

- Περιοδικό Μεταξοτυπίας, ISS Long Beach, Ink Kitchen, A.W.T. World Trade, CCI Chemicals Belgium, Siegwerk, Dow Chemical Company.

We also work with chameleon pigments, silicone ink flexibility, security ink features, metal substrate printing, wood printing techniques, glass ink adhesion, και EMI shielding inks. Our work covers υβριδικά συστήματα μελάνης, binder formulations, και nano-particle ink technology.

7. Future Trends in Specialty Inks

The world of inks is not still. New ideas are coming fast. Look at these trends:

- Nanotechnology Advances:

- We see nano-particle ink technology και self-healing inks.

- They give a new look to prints.

- Smart Inks:

- Inks can hold embedded QR codes και NFC-enabled prints.

- They help in the digital age.

- Circular Economy:

- Our inks are biodegradable.

- They bring a circular economy to life.

- 3D Screen Printing and Hybrid Systems:

- We see direct-to-garment printing synergy with 3D printing.

- New methods mix screen prepress workflows και automated ink dispensing.

- Expanded Substrate Compatibility:

- More uses for ceramic ink printing, industrial ink applications, conductive inks for electronics, και fine art screen printing.

- Improved Quality Controls:

- Better ink shelf life optimization και red shift color effects help many brands.

- Micro-registration adjustments και static control in printing add to smooth operations.

8. Conclusion & Actionable Takeaways

We have learned a lot. Here are the big points:

- Ειδικά μελάνια are key tools for screen printers.

- There are many types: metallic inks, thermochromic inks, μελάνια που λάμπουν στο σκοτάδι, Μελάνες που σκληρύνονται με υπεριώδη ακτινοβολία, puff inks, και άλλα.

- Think of substrate compatibility, αντοχή, environmental standards, curing methods, και κόστος when you choose an ink.

- Many challenges, like adhesion issues και ταίριασμα χρωμάτων, have clear solutions.

- Real cases from Nike, Coca-Cola, and Panasonic show that our inks work well.

- DIC Graphics leads with ink innovations, like our UV-Graphicure™ series και INVIA™ Secure μελάνια.

- The future brings new ideas with nanotechnology, smart inks, και circular economy moves.

Take action today. Learn more of our work by visiting our pages on Magenta Specialty Ink, Black Specialty Ink, και Extra Black Specialty Ink. You can also see our Purplish-Red Specialty Ink page for more ideas.