Screen Printing Plastisol Ink is a versatile and durable ink designed specifically for fabric printing. It is the industry standard for screen printing due to its vibrant colors, opacity, and ease of use. Ideal for printing on dark and light garments, Plastisol ink creates bold, long-lasting prints that withstand multiple washes without fading or cracking.

- High Opacity: Offers excellent coverage, especially on dark garments.

- Vibrant Colors: Produces bright, vivid prints that stand out.

- Versatile Application: Suitable for cotton, polyester, and blends.

- Smooth Consistency: Easy to work with, ensuring even prints.

- Durable Finish: Resists cracking, peeling, and fading over time.

- Non-Water-Based: Does not dry out in the screen, allowing for extended working time.

- Wide Color Range: Available in standard, metallic, fluorescent, and custom colors.

- Longevity: Ensures prints remain vibrant and intact after multiple washes.

- Consistency: Reliable performance with every print, reducing waste and improving productivity.

- Ease of Use: Ideal for beginners and professionals alike, thanks to its forgiving nature and extended open time.

- Customizability: Mixes well with additives to achieve various effects, such as puff, gloss, or matte finishes.

- Viscosity: Medium to high, depending on the formula.

- Flash Time: 3-7 seconds at 220°F (105°C).

- Curing Temperature: 320°F (160°C) for 1-2 minutes.

- Mesh Count: Best used with 110-160 mesh screens for optimal coverage.

- Shelf Life: Up to 2 years when stored properly.

- Heat Press: Cure at 320°F (160°C) for 1-2 minutes. Ensure the entire print reaches this temperature to avoid under-curing, which can lead to washout.

- Conveyor Dryer: Adjust the speed and temperature so that the ink reaches 320°F (160°C) for the recommended time. Testing is advised to ensure proper curing.

- Screen Cleaning: Use a screen wash or mineral spirits to remove excess ink from the screen. Plastisol ink does not dry in the screen but should be cleaned promptly to avoid buildup.

- Tools & Equipment: Clean squeegees, spatulas, and other tools with a compatible solvent cleaner immediately after use to prevent ink from hardening.

- Temperature: Store in a cool, dry place between 65-90°F (18-32°C).

- Container: Keep the container tightly sealed when not in use to prevent contamination and drying out.

- Shelf Life: If stored properly, the ink will remain usable for up to 2 years.

- Packaging: Ensure containers are sealed tightly to prevent leaks. Use secondary packaging, such as plastic bags or spill-proof containers, for added protection.

- Temperature Control: Avoid exposing the ink to extreme temperatures during transport. High temperatures can cause the ink to become too fluid, while freezing temperatures may lead to separation.

- Handling: Handle with care to prevent punctures or spills. Transport upright and securely to minimize movement.

- Refer to the Safety Data Sheet (SDS) for detailed safety and handling information.

- Use protective gloves and eyewear when handling ink.

- Ensure proper ventilation during application and curing.

Puff Ink for Screen Printing – High Density 3D Effect Ink for Textiles

Smell: No odor plastisol ink, can be used indoors and outdoors

Elasticity: Good stretch for stretch fabrics

Durability: Good wash fastness and color stability.

Durability: High wash fastness and not easy to fade.

Printability: Smooth application with minimal bleeding.

High Opacity: All have good opacity

Characteristics: Excellent covering power

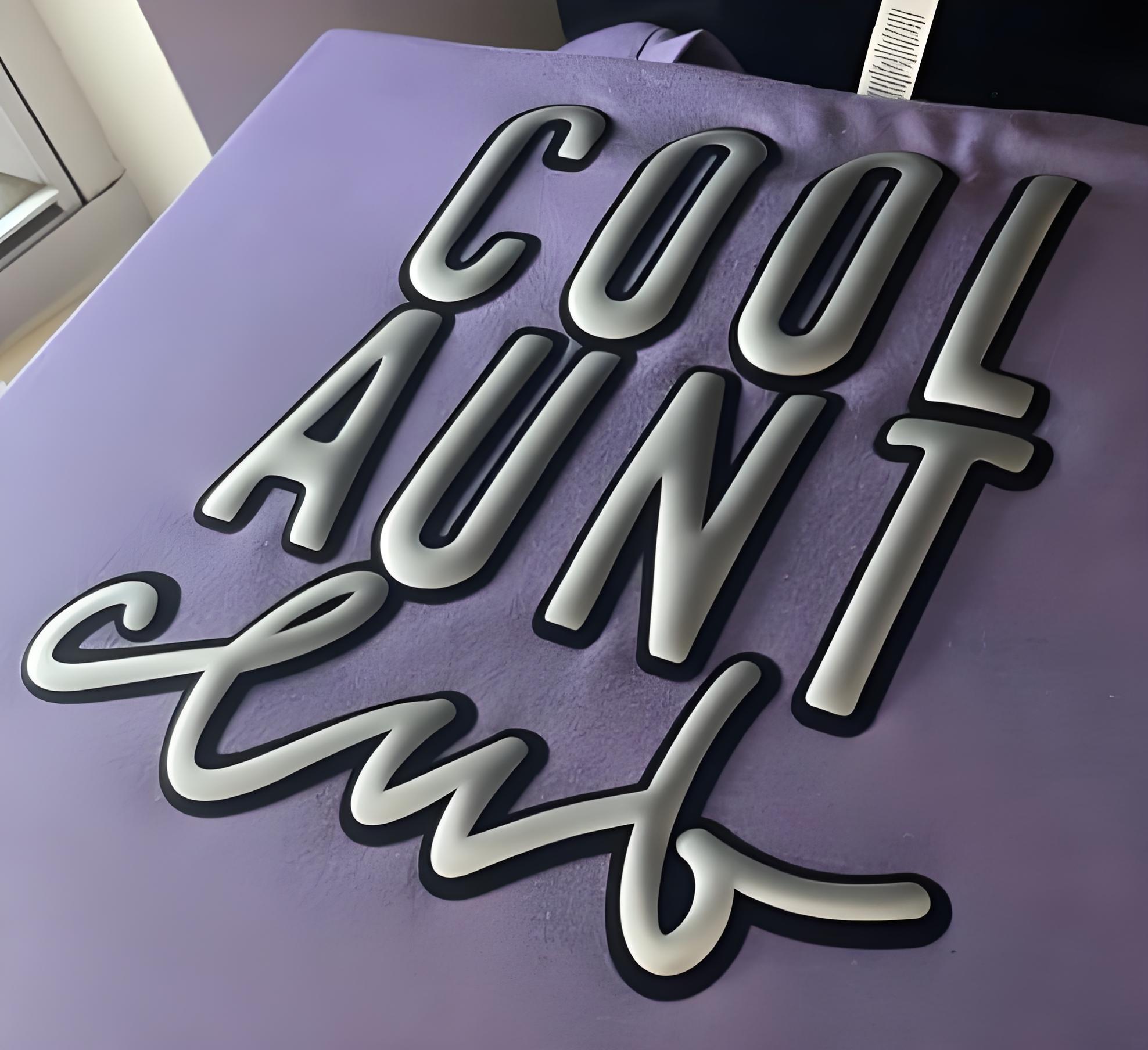

For professional screen printers, achieving a 3D High-Density (HD) look usually means expensive capillary films and slow production speeds. HONG RUI SHENG Puff Plastisol Ink changes the game. Our formulated puff ink screen printing solution allows you to achieve that premium, rounded, “marshmallow” dimension with just one or two print strokes.

Unlike generic puff inks that collapse in the dryer or feel like rough sandpaper, our HRS-PUFF series is engineered for controlled expansion stability. We give you the loft you want, with the soft, elastic hand feel your brand customers demand.

Why sourcing from us?

Direct Factory Price: No middleman markups.

Batch Consistency: Every bucket has the exact same blowing agent ratio.

Custom ODM: We can adjust the “puff height” and “softness” based on your fabric requirements.

Key Features & Benefits

✅ Stability That Doesn’t Collapse

The biggest nightmare with puff ink is the “soufflé effect”—it rises in the dryer and collapses when it cools. Our unique chemical formula has a wider heat tolerance window, ensuring the air bubbles inside the ink remain stable even if your conveyor dryer temperature fluctuates slightly.

✅ Premium “Velvet” Texture

Cheap puff inks feel like hard plastic or styrofoam. Our formula integrates a soft-hand elastic resin, creating a surface that feels rubbery, smooth, and premium—perfect for high-end streetwear and hoodies.

✅ Excellent Opacity & Coverage

Whether you are printing on black cotton or polyester blends, our opacity is top-tier. For polyester, we recommend using our grey dye blocker as an underbase to prevent dye migration.

✅ Eco-Friendly & Compliant

We understand the strict regulations in the EU and US markets. Our inks are:

Phthalate-Free

Heavy Metal Free

PVC-Resesin Optimized (Low odor)

Technical Specifications (Data Sheet)

To ensure the best results in your production line, please follow these parameters established by our lab.

| Parameter | Specification | Professional Advice |

| Ink Type | Plastisol Based Puff | Ready-to-use (or mix with pigments) |

| Mesh Count | 86 – 110 (34T – 43T) | Crucial: Higher mesh (150+) will NOT deposit enough ink to puff. |

| Squeegee | 60/90/60 or 60 Durometer | Use soft/medium squeegee to lay down a thick deposit. |

| Emulsion | High Density / Thick Coat | Use a 2+1 coating method for a thicker stencil (EOM). |

| Curing Temp | 150°C – 160°C (300°F – 320°F) | Do not overheat. Temps above 170°C will cause collapse. |

| Flash Temp | 100°C – 110°C | Just touch dry. Do not fully cure the puff at the flash station. |

Application Guide: How to Print Perfectly

As your solution partner, HONG RUI SHENG wants to ensure your success. Follow these steps for the perfect 3D effect:

Screen Prep: Create a thick stencil. The more ink you can hold in the screen, the higher the puff will be.

The Underbase Strategy:

For 100% Cotton: You can print puff ink directly.

For Stretchy Fabrics: Print a clear underbase using our [Plastisol Ink] clear base first. This acts as “glue” to prevent the puff from cracking when the shirt is stretched.

Printing: Use a sharp print stroke. Keep your “off-contact” distance slightly higher (3-5mm) to ensure the screen snaps off cleanly from the thick ink deposit.

Curing (The Secret): Run your belt speed slightly slower. Puff ink needs time to rise gently (like baking bread). A sudden heat shock can cause a rough, “popcorn” surface.

Frequently Asked Questions (FAQ)

Q: Can I mix this puff ink with other colors?

Yes! You can mix our puff base with standard plastisol ink pigments to create custom colors. However, keep in mind that the color will lighten (turn pastel) as the ink expands and the pigment spreads out.

Q: Why does my print look rough/bubbly?

This is usually “Over-Cure” or “Heat Shock.” Your dryer is too hot, causing the blowing agent to boil violently. Lower your temperature by 5-10 degrees and slow down the belt.

Q: Can this be used on automatic machines?

Absolutely. Our viscosity is adjusted for both manual and automatic oval/carousel machines. It does not dry in the screen, allowing for long production runs.

Related products

- Special Series

Metallic Gold Screen Printing Ink