Table of Contents

Custom Silk Screen Printing Services: Your Guide to Durable, High-Quality Designs

This article is a simple guide. You will learn about custom silk screen printing services and quality screen print solutions. We will use easy words to help you with custom t-shirts. This guide shows the process, benefits, costs, and examples. We use short, clear sentences.

What is Silk Screen Printing?

Silk screen printing is a process to put ink on many surfaces. This method is very durable and gives vivid colors on clothes and more. It is used for silk screening services. t-shirts, hoodies, bags, and many other items.

- Custom silk screen printing lets you print a design made just for you.

- Quality screen print solutions mean the printed design looks good and lasts long.

This method has been used for a long time. It gives a unique logo to your custom t-shirts. great look to your items and is one of the best ways to print in bulk orders.

Why Choose Custom Silk Screen Printing?

Choosing custom silk screen printing has many benefits. Here are some good reasons:

- Durability: The ink lasts a long time, even with many washes.

- Vibrant Colors: The colors are bright and rich.

- Cost-Effective for Bulk Orders: If you print many items, the price is lower per piece.

- Versatility: You can add custom screens to clothes, bags, posters, and more, especially for printed t-shirts.

- Eco-Friendly Options: Many printers use eco-friendly inks that are safe for the earth.

You can choose screen printing when you need custom work that is consistent and of high quality. Many brands and businesses use screen printing for their apparel and promotional products.

The Silk Screen Printing Process

The screen printing process The order is broken into printed t-shirts and other merchandise. simple steps. Here is how it works:

- Artwork Preparation

- You give your design in a clear file.

- Use vector formats like AI or EPS.

- Pantone Matching System (PMS) is used so the colors match well.

- Screen Setup

- A mesh or screen is prepared.

- The screen is coated with a special liquid.

- A light exposes the screen to fix the design.

- Use the right mesh count for details.

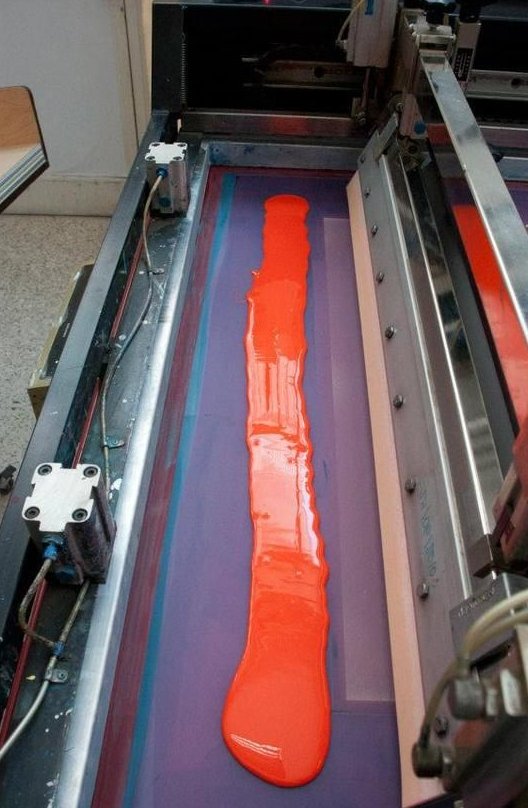

- Printing

- Plastisol inks and water-based inks are very common.

- The ink is pressed through the screen onto the fabric.

- Different ink types give different effects. For example, metallic inks or They offer glow-in-the-dark printed t-shirts. inks may be used.

- Drying/Curing

- The items go into a dryer.

- A proper cure makes the ink set well.

- Quality Check & Packaging

- Each item is checked.

- Mistakes are fixed.

- The products are then made ready for shipping.

This process helps to ensure that the final print is bright and long-lasting.

Designing for Silk Screen Printing

When you design for screen printing, you need to follow simple steps:

- Artwork File Formats: Use files like AI, EPS, PSD, or PNG. Always work in high resolution for your screen printing company.

- Color Separation: Separate each color in your design. This helps the printer know where to put each ink.

- Best Practices with Pantone: Use the Pantone Matching System (PMS). This guarantees that the colors come out correctly.

- Creative Ideas:

- Try halftones for a soft look.

- Use specialty inks like glow-in-the-dark or puff inks.

These steps help your design to look great when printed. Simple designs work best.

Pricing & Turnaround

The cost of screen printing depends on many factors. Use this simple list:

- Cost Factors:

- Number of Colors: More colors mean more work.

- Order Size: Big orders cost less per piece.

- Ink Type: Plastisol vs. eco-friendly options.

- Average Prices:

- T-shirts: About $3 – $8 each in bulk.

- Posters/Bags: Around $2 – $5 each.

- Turnaround Time:

- Standard orders take time, especially when using a screen printing company. 7–10 days.

- Rush orders may be done in 2–3 days with a higher cost.

This data shows that bulk orders are smart for saving money. Even with rush orders, you get a quality product.

How to Choose a Quality Screen Print Provider

When you look for a screen print provider, ask these questions:

- Do they offer Pantone color matching?

- What certifications do they have? (e.g., ISO 9001, Oeko-Tex)

- Can you get a sample or proof?

- What is the best method for custom screen printing? The minimum order quantity (MOQ) is essential for screen printer services.?

- Do they help with your silk screening services? artwork setup?

- What do they do if there are mistakes?

Also, watch for red flags:

- No portfolio or reviews.

- Prices that are not clear.

- Bad communication.

A good provider will answer all your questions and show their work. This gives you confidence in their service.

Applications of Silk Screen Printing

Screen printing can be used in many projects. See this list:

- Apparel:

- T-shirts

- Hoodies

- Hats

- Uniforms

- Promotional Products:

- Tote Bags

- Posters

- Drinkware

- Event Branding: Custom screen printed items can enhance your brand’s visibility.

- Concerts

- Marathons

- Trade Shows

- Limited-Edition Merchandise:

- Artist Collaborations

- Special Projects involving custom t-shirt printing can attract more customers.

You can use screen printing to make a big impact in how people see your brand. It is a versatile A great way to share your message is through personalized printed t-shirts.

Case Studies, Data, and Statistics

Below is a table with important data. These facts come from industry reports and studies. They help us understand how good screen printing is and why it is used.

| Data Point | Details | Source |

|---|---|---|

| Market Size & Growth | The global market was $3.5B in 2022 and will grow by 4.8% CAGR. | Grand View Research (2023) |

| Top Applications | 76% of orders are for apparel; 20% for promos; 4% for signs. | Impressions Expo Industry Survey (2023) |

| Bulk Order Savings | Orders over 100 units can lower cost by 30–50%. | Ryonet Cost Analysis (2023) |

| Eco-Friendly Demand | 42% of businesses prefer eco inks and safe fabrics. | FESPA Sustainability Report (2023) |

| Customer Retention | Custom prints can boost brand recall by 58%. | HubSpot Merch Marketing Study (2023) |

| Common Order Sizes | Small businesses order 100–500 units; large orders can be 1,000+. | Printful Case Study (2023) on custom t-shirt printing strategies |

| DTG vs. Screen Printing | Screen printing is 40% cheaper for orders over 50 units. | Printify Pricing Guide (2024) |

| Color Limitations | 92% of pros say to use no more than 6 colors per design. | SGIA Best Practices Guide (2023) |

| Case Study: Brewery Branding | A craft brewery saw 18% sales growth with screen-printed merch. | Screen Printing Magazine (2023) |

| Case Study: Nonprofit Fundraising | A nonprofit raised $12K by selling 500 tote bags with screen printing. | Nonprofit Quarterly (2023) |

| Waste Reduction | Automated presses lower ink waste by 25% compared to manual setup. | M&R Environmental Impact Report (2023) |

| Top Pain Points | 65% of users worry about inconsistent color matching. | Printing United Alliance Survey (2024) |

| Design Turnaround | Standard orders take 7–10 days; rush orders take 2–3 days with a 20% extra cost. | Custom Ink Benchmark Data (2024) |

| Popular Inks | Plastisol ink is used by 68% of pros; water-based ink is growing at 12% YoY. | Wilflex Ink Trends Report (2024) |

| Employee Safety | OSHA-compliant shops see 35% fewer injuries. | U.S. Bureau of Labor Statistics (2023) |

| Case Study: Sports Team Merch | A college team sold 1,200 jerseys in 3 months, with custom t-shirts leading the sales. 40% more fan engagement. | Athletic Business Journal (2024) |

| Regional Preferences | The Southern U.S. has 22% more demand for screen printed apparel than sublimation. | IBISWorld Regional Market Data (2023) |

| Customer Loyalty | 80% of clients return to printers with free design templates and Pantone matching. | Vistaprint Customer Insights (2024) |

Key takeaways:

- Bulk orders lead to big savings.

- Eco-friendly options are in high demand.

- Pantone Matching is very important to get the colors right.

- Some customers worry about color matching.

- Fast turnaround is available, but at a cost.

This table shows that screen printing is a well-used, trusted method. It works well for many uses. The data is clear and helps you make a smart choice.

Our Step-by-Step Process Recap

We can show a simple list of our screen printing steps:

- Start with Your Artwork

- Use a clear file

- Follow best practices with Pantone

- Make sure it is high quality for your custom screen printed garments.

- Prepare the Screen

- Coat with a liquid

- Expose with light

- Set the design on a proper screen

- Print Your Design on custom t-shirts for a personal touch.

- Choose your ink: Plastisol or water-based

- Use the screen to transfer the ink

- Dry and Cure

- Use a dryer to cure the ink

- Check for quality

- Pack and Send

- Inspect the items

- Pack them well

- Send them to you

These steps are clear. They help you get high-quality They produce printed items that are perfect for custom embroidery. strong and bright.

Why Bulk Orders Are Best

Bulk orders allow you to save money. This is why many people and companies choose screen printing:

- Saves Cost: Orders over 100 units cost less.

- More Consistency: Every item looks the same.

- Better for Big Events: Use them for sports teams, fundraisers, and more.

Bulk orders make custom designs affordable. Many shops offer discounts for bulk printing.

Example: A small business orders 200 t-shirts. They pay less per shirt. This is a smart way to invest in branded items.

Eco-Friendly Screen Printing

Many print shops now offer eco-friendly ink options. These inks are safe for our planet and good for your brand image.

- Eco Options:

- Water-based inks are popular.

- They have a low environmental impact.

- Certifications:

- Look for shops with ISO 9001 and Oeko-Tex. These show the product meets high safety and quality standards.

Eco-friendly printing is a win-win. You get beautiful prints and help the earth by choosing eco-friendly custom screen printing services.

Remember: The demand for eco-friendly prints is high. Studies show 42% of businesses care about green options.

Quality and Safety in Your Prints

Quality is very important in screen printing. A good printer will make sure:

- Color Matching: Your design has the exact colors.

- The Pantone Matching System (PMS) is used.

- Ink Type: Use the right ink for the job in custom t-shirt printing.

- Plastisol is common.

- Water-based inks are good for a soft feel.

- Safety:

- A good shop is OSHA-compliant.

- This means fewer injuries and safer work.

Tips for Quality:

- Ask questions:

- Can I see your samples?

- Do you offer free design templates?

- Watch for red flags:

- No reviews or unclear prices.

Good quality means you get a durable product that looks great.

DTG vs. Screen Printing

Some people ask: Should I use DTG or screen printing? Here is a simple comparison:

| Feature | Screen Printing | DTG Printing |

|---|---|---|

| Cost | Cheaper for orders over 50 units. | Better for small batches (<25). |

| Color Quality | Vivid and rich colors. | Great for detailed images. |

| Best For | Bulk orders and custom designs. | Short runs and full color prints. |

Screen printing is 40% cheaper for big orders. DTG is a good choice for very small orders. Choose the method that fits your needs.

How to Order with a Quality Screen Print Provider

When you are ready to order, follow these steps:

- Do Your Research:

- Look for a shop with good reviews.

- Check their portfolio.

- Ask Important Questions:

- Do they have Pantone matching?

- Do they offer samples?

- What is the MOQ?

- Is there help with artwork?

- Review Their Data:

- Are they known for bulk orders and fast turnaround?

- Do they show green and eco-friendly options?

A well-known provider often gives a free quote. This makes you feel safe when you order.

Applications of Screen Printing for Every Need

Screen printing is versatile. Here are many ways to use it:

- For Apparel:

- T-shirts for your team

- Hoodies for cool style

- Hats for a smart look

- For Brands:

- Promotional products help your brand stand out.

- Event branding like banners and posters boosts your image.

- For Special Uses:

- Nonprofits use printed tote bags to raise funds.

- Sports teams use jerseys to show team pride.

- For Art:

- Local artists can use it to sell limited-edition prints.

These uses show that screen printing is for anyone. It is a quality solution for many needs.

More About Our Process and Your Choices

Here is a quick recap:

- You bring your artwork.

- We set up the screen with Pantone matching.

- We print with plastisol or water-based ink.

- We dry and cure the print.

- You get high quality and durable items.

With these simple steps, you know what to expect. Our process gives you a high-quality product that is long-lasting.

Why Our Data Matters

Our facts come from trusted sources. Look at some important points:

- The The global screen printing market is expanding with custom garment options. was $3.5B in 2022. This shows that many people trust screen printing.

- 76% of orders are for apparel. That means most use screen printing for brands and teams.

- Bulk orders can reduce cost by 30-50%. This helps you save money on large projects.

- Eco-friendly inks are in high demand. Grow your brand by choosing good, green options.

- A nonprofit raised $12K with tote bag orders. This shows screen printing can help raise funds.

These facts help you see why screen printing is a trusted method for many projects.

Tables and Lists for Quick Info

Here is another table to help you compare key info:

| Step | What Happens | Why It Matters |

|---|---|---|

| Artwork Prep | Provide a clear file in AI, EPS, or PNG | Good quality file makes printing neat. |

| Screen Setup | Coat and expose the screen | Ensures sharp, clear prints. |

| Ink Choice | Choose between plastisol or water-based inks | Decides durability and eco friendliness. |

| Drying/Curing | Use a dryer to cure the ink | Sets the ink to last long. |

| Quality Check | Inspect each item | Avoids mistakes and reprints in custom t-shirt printing projects with our silk screening services. |

You can also use this list for a quick memory:

- Artwork File

- Screen Setup

- Drying

- Quality Check

With these points, you can see the full picture of screen printing.

Customer Stories

Customers tell us good things. A craft brewery used screen printing on their hoodies and hats. They saw an impressive tee design. 18% There has been a rise in sales for custom printed t-shirts. A nonprofit sold 500 tote bags and raised awareness for custom screen printed apparel. $12K for their cause. A college sports team sold 1,200 jerseys in three months, and fan joy grew by 40%.

These real stories help you trust screen printing. They show that quality screen print solutions work for many needs.

Key Points to Remember

- Bulk orders save you money.

- Eco-friendly inks show care for the planet.

- Pantone matching keeps your colors true.

- Ask detailed questions when choosing a provider.

- Our process is simple and proven.

Using custom silk screen printing is a smart way to get your design on many items. It is good for businesses, sports teams, and artists alike.

Conclusion

Custom silk screen printing services give you a way to show your best designs. With quality screen print solutions, you get:

- Vibrant prints

- Long-lasting designs

- Cost savings with bulk orders

- Eco-friendly choices

By using trusted methods, Pantone Matching, and a clear process, you can be sure that your printed items will be both beautiful and durable.

If you need more help, ask your provider about:

- Free design templates

- Pantone matching

- Fast, high-quality printing

Feel free to visit our website and get a free quote today. Let us help you make your design dreams come true!