Table of Contents

Learn how to start screen printing at home with this detailed beginner’s guide. Discover essential tools, step-by-step instructions, and expert tips to create high-quality prints on fabric, paper, and more.

Screen printing at home is a creative and rewarding process. Whether you want to print designs on shirts, tote bags, or posters, this guide will help you get started with a simple and affordable setup.

You’ll learn about the essential tools, the screen printing process, and practical tips to avoid common mistakes. Follow this step-by-step guide and start creating professional-quality prints at home.

What is Screen Printing?

Screen printing, also known as silkscreen printing, is a printing technique that uses a stencil and mesh screen to transfer ink onto a surface. This method is widely used for:

- T-shirts

- Hoodies

- Tote bags

- Posters

- Decals

- Custom apparel

The process involves coating a screen with emulsion, exposing it to light, and then using a squeegee to push ink through the stencil onto the material.

Essential Screen Printing Kit

To get started, you’ll need the following tools and supplies:

Must-Have Tools and Supplies:

- Screen printing frame

- Mesh screen

- Emulsion

- Screen printing ink (water-based or plastisol)

- Squeegee

- Transparency film for your design

- Light source for screen exposure (sunlight or lamp)

- Washout booth or sink

- Drying rack

- Cleaning supplies

- Maintenance kit

Optional Tools:

- Screen printing press

- Heat press

- Drying rack

- Storage solutions

This kit is suitable for beginners and those starting a small screen printing business.

Step-by-Step Guide to Screen Printing

Follow these steps to create your first screen print:

1. Design Your Artwork

- Use design software like Adobe Illustrator, Photoshop, CorelDRAW, GIMP, or Inkscape.

- Canva is a good option for simple designs.

- Print your design on transparency film.

2. Prepare Your Screen

- Coat the screen with emulsion.

- Let it dry in a dark place.

- Place your transparency film on the screen.

- Expose the screen to a light source.

3. Wash Out the Screen

- Rinse the screen to reveal the stencil.

- Let it dry completely.

4. Set Up Your Workspace

- Use a flat surface or a screen printing press.

- Keep your area clean and organized.

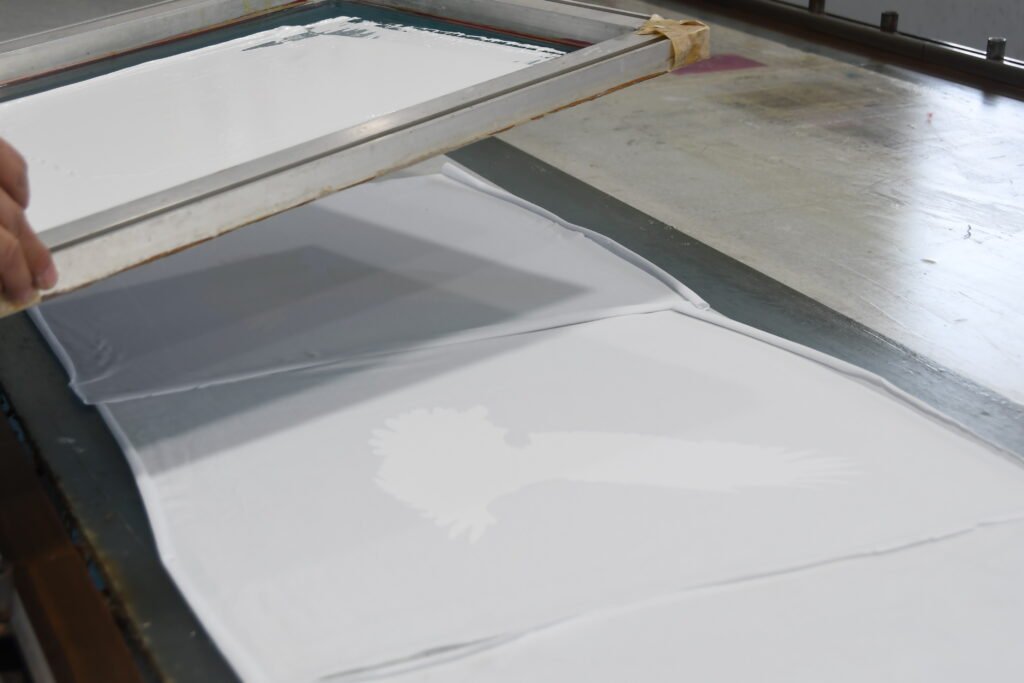

5. Print Your Design

- Place the material (e.g., T-shirt, tote bag) under the screen.

- Apply ink to the screen.

- Use a squeegee to push ink through the screen.

- Lift the screen carefully to reveal your print.

6. Cure the Ink

- Allow the print to dry.

- Use a heat press, heat gun, or dryer for proper curing.

Tips for Successful Screen Printing

1. Keep Your Workspace Clean

A clean area ensures smooth printing and prevents unwanted ink smudges.

2. Start with Simple Designs

Practice with basic shapes and one-color prints before moving to complex designs.

3. Use the Right Ink

- Water-based ink creates a soft feel.

- Plastisol ink is more durable.

4. Ensure Proper Alignment

Good registration and alignment improve print quality.

5. Experiment with Different Materials

Try printing on fabrics, wood, glass, and metal to expand your creativity.

Common Mistakes to Avoid

- Not cleaning screens properly.

- Rushing the drying process.

- Using too much or too little ink.

- Skipping the curing step.

- Misaligning the design.

Budget-Friendly Tips for Beginners

1. Use DIY Equipment

- Sunlight can replace an exposure unit.

- A simple flat board can act as a press.

2. Buy Used Supplies

- Check Craigslist, eBay, and Alibaba for deals.

3. Reuse and Maintain Equipment

- Clean screens with eco-friendly cleaning solutions to extend their lifespan.

4. Start with a Beginner Kit

- Popular kits include Speedball and Ryonet.

Quick Reference Table

| Category | Details |

|---|---|

| Cost to Start | $50–$100 for basic kits, $200–$500 for full setup |

| Time Required | 2–4 hours per project |

| Most Common Use | 75% print T-shirts, others print tote bags and posters |

| Popular Ink Type | 60% prefer water-based ink, others use plastisol |

| Exposure Time | 5–10 minutes with DIY light, 1–2 minutes with a pro unit |

| Safety Tip | 95% recommend gloves, masks, and good ventilation |

| Cleaning Benefit | Proper cleaning extends screen life by 2–3 times |

| Profit Potential | Many earn $500–$2,000 per month |

| Eco-Friendly Option | Water-based ink is 50–60% more sustainable than plastisol |

| Community Support | Join online forums and groups for help |

Learn More and Get Inspired

- Ink Selection Guide – Learn about different types of screen printing inks.

- DIY Screen Printing Tutorial – A full course on print methods and techniques.

- Screen Printing Equipment Guide – A detailed list of recommended tools and materials.

Final Thoughts

Screen printing at home is an exciting and creative process. Whether you’re doing it as a hobby or starting a business, the right tools and techniques will help you succeed.

Key Takeaways:

- Use the right supplies for the best results.

- Follow the step-by-step guide carefully.

- Learn new techniques through online tutorials and forums.

- Practice regularly to improve your skills.

With time and effort, you can create stunning prints on clothing, posters, and other materials. Get started today and bring your designs to life!