Key Points to Remember

- Plastisol ink is the pinnacle choice for display screen printing brilliant, long lasting, and high-detail snap shots.

- The four colour system (CMYK) makes use of cyan, magenta, yellow, and black process inks to breed full-colour snap shots.

- Process inks must be precisely combined and implemented for proper coloration blending and photorealistic prints.

- Screen, mesh rely, and gadget first-class immediately have an effect on photograph sharpness and final print pleasant.

- Mix, flash, and treatment each plastisol ink layer nicely for first-class consequences and material experience.

- Choose phthalate free inks and comply with safety pointers for a cleanser, safer print save.

- Maintaining color method plastisol ink standards ensures each screen print pops with vibrant shade and detail.

Unlocking the magic of CMYK and plastisol opens a international of innovative, professional-pleasant display printed garb and products—get started out and experience the colorful adventure!

Everything You Need to Know About Plastisol Ink,CMYK, and the Four Color Process for High-Detail Screen Printing

Want to liberate colourful, sharp, complete-coloration prints on t-shirts and different clothes? In this whole manual, you’ll discover how plastisol ink and the 4 shade system (CMYK) come together to create high-detail, photorealistic screen prints. Whether you’re new to display printing or trying to improve your manner, this newsletter will stroll you via the science, system, ink systems, coloration blending, and seasoned tips for expert results.

Esquema do artigo

- What is Plastisol Ink? Review & Overview

- The Science Behind Plastisol Inks in Screen Printing

- How Does the Four Color Process (CMYK) Work in Screen Printing?

- Exploring CMYK: What Are Process Colors?

- The Role of Plastisol Ink in the Color Process

- Understanding Process Black, Cyan, Magenta, and Yellow Inks

- How to Achieve Photorealistic and High-Detail Prints with CMYK Plastisol Ink

- What Equipment and Mesh Count Do You Need?

- Mixing, Flashing, and Curing: Perfecting the Final Print

- Safety, Environmental Concerns, and Phthalate-Free Plastisol Options

- Frequently Asked Questions: Tips for the Best Ink Results

1. What are plastisol inks? Review & Overview

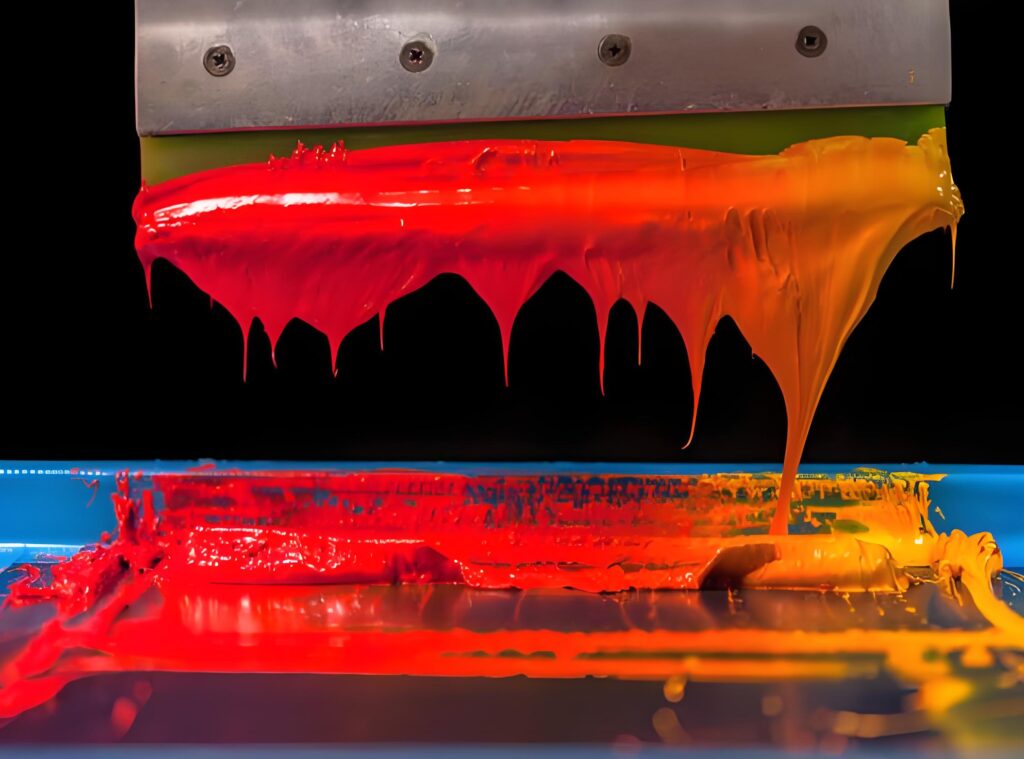

Plastisol inks are the undisputed champions of the screen printing world, widely used by professionals for their consistency, versatility, and range of vibrant colors. Unlike water-based inks, plastisols do not dry by evaporation or absorption, but are cured by heat. This unique characteristic makes plastisol inks a favorite for screen printing projects that require crisp lines and vibrant, long-lasting colors.

Review after review has praised plastisol inks for their ability to produce opaque, highly detailed patterns even on colored or dark garments. When looking for an ink system that can handle intricate patterns, text, or photographic-quality images, plastisol remains the industry-standard ink for screen printing needs. The smooth texture and soft feel also make it popular for apparel.

2. The Science Behind Plastisol Inks for Screen Printing

Plastisol is a suspension of PVC particles in a plasticizer. It does not dry on its own and requires sufficient heat (usually above 320°F) to fully cure. This is what distinguishes plastisol inks from traditional dye or water-based inks. Its translucent nature is critical to mixing process colors while maintaining color strength.

For screen printers, understanding this chemistry means you can skillfully use inks to suit your substrates and garments. Because plastisol adheres to the surface of the fibers rather than soaking into them, it produces clear, vibrant results – especially important for realistic or highly detailed prints.

3. How does the four-color process (CMYK) work in screen printing?

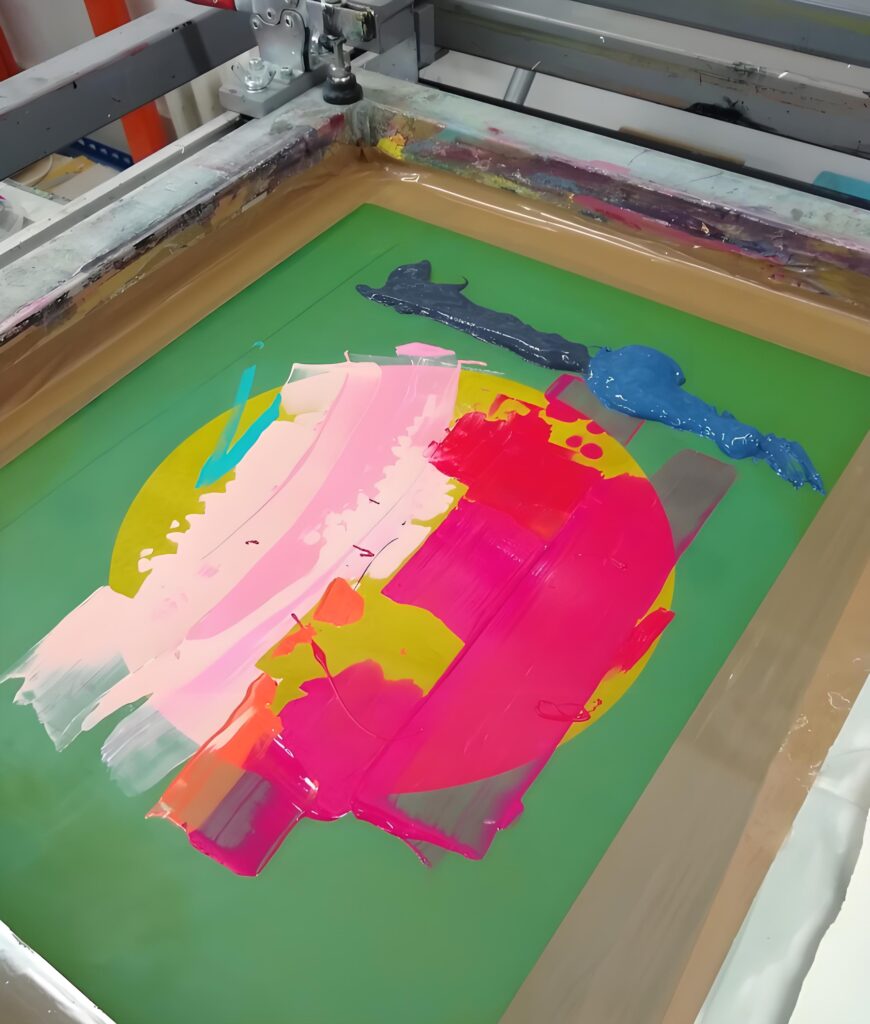

The four-color process (CMYK, i.e. cyan, magenta, yellow and process black) is the cornerstone of full-color screen printing. By combining these process inks in varying amounts, it is possible to reproduce almost any color image through a technique called halftone printing.

Instead of mixing all the colors to match each design, CMYK uses small dots of each color in a specific pattern on the screen. When viewed from a distance, these dots visually blend to form continuous tones, allowing you to print images, gradients, and intricate designs with stunning detail using only one complete set of four-color process CMYK plastisol inks.

4. Explore CMYK: What are Craft Colors?

CMYK – Cyan, Magenta, Yellow and Black (K stands for “Key” or Craft Black) – are known as Craft Colors. When mixed properly, these four inks can produce full-color photorealistic images for professional screen printing projects.

Cyan: Provides vivid blues and greens

Magenta: Provides vivid reds and purples

Yellow: Produces brilliant yellows and oranges

Black (process black): Deepens shadows, sharpens details and enhances contrast

Using translucent inks and strategically layering them, printers can achieve depth, nuance and near-photographic quality on anything from T-shirts to posters.

5. Plastisol inks in the color printing process

Why are plastisol inks so effective in the color printing process? The answer: its molecular structure allows for precise, repeatable printing of process colors. Unlike some ink types that may bleed or lose color intensity, plastisol provides a consistent, vibrant appearance and crisp detail.

When using color-finish plastisols, it is important to maintain the correct thickness, mesh count, and underlay (for dark garments) so that the color finish will achieve the desired results. What are the results? Four-color processed or four-color processed plastisol inks capture every shadow and highlight in the image.

6. Understanding Process Black, Cyan, Magenta, and Yellow Inks

Process black (sometimes called “K” in CMYK) isn’t just a deeper form of the standard black plastisol. It’s specially formulated to work harmoniously with process colors for better shadow, contrast, and detail. The black ink in 4 color process fills in gaps and enhances the sharpness of your print.

Meanwhile, process cyan, magenta, and yellow are semi-transparent, allowing overlaps to form secondary and tertiary hues—transforming the three primary colors into a rainbow of possibilities. Choosing the right plastisol ink formulation ensures your colours to mix deliver a full, vibrant spectrum.

7. How to Achieve Photorealistic and High-Detail Prints with Tinta CMYK Plastisol

Creating photo-quality, high-detail images on fabric means controlling every variable:

Screen mesh count: A higher mesh count (230 or above) is required to hold fine halftone dots for crisp images and smooth gradients.

Correct ink thickness and transparency: Each process ink must pass through the mesh without flooding or clogging.

Precise color separation with software: The original image is separated into halftones, with each color placed in the right order on the press.

Tight registration: All four screens must align perfectly so the overlapping process inks blend seamlessly, resulting in a sharp, photorealistic final print.

8. What Equipment and Mesh Count Do You Need?

The best results require specialized equipment: a good exposure unit for burning screens, a proper screen press (manual or automatic), squeegees with the right durometer, and a conveyor dryer for consistent cure.

Mesh count: For process cmyk inks, a mesh count of 230 to 305 is standard, allowing tiny halftone dots to pass while ensuring detailed prints.

Flashing and drying: You may need to flash between colors to prevent ink overlap or color bleed. Each plastisol layer must be tack-free before printing the next.

Heat curing: A consistent cure at the right temperature is essential for proper washability and longevity.

9. Mixing, Flashing, and Curing: Perfecting the Final Print

Mixing your Tinta plastisol CMYK set can be done directly or by purchasing a complete set of pre-formulated process inks. Always stir thoroughly to maintain pigmentation, and use additives sparingly where needed for flow or softness.

Flashing between colors helps prevent unwanted color overlap and keeps each screen print layer sharp. Once all colors are down, curing in a tunnel dryer locks the pigment into the substrate fibers, ensuring colour longevity and durability. Properly cured plastisol ink creates a smooth, soft hand on a wide range of garments.

10. Safety, Environmental Concerns, and Phthalate-Free Plastisol Options

Plastisol ink traditionally contains PVC and phthalates, substances with potential health or environmental risks. In response, many brands now offer phthalate free and eco-friendly ink systems for screen print applications.

Safe ink use also means proper ventilation, protective gloves, and routine workplace hygiene. Dispose of ink and waste according to your local guidelines to protect yourself and the environment.