Índice

Tinta plastisol de alta densidade: o cambio de xogo na serigrafía

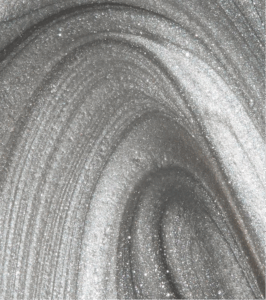

Tinta plastisol de alta densidade is changing the world of screen printing. This thick, strong ink lets you make 3D designs, cores brillantes, and prints that last for years. Let’s learn how it works and why you should try it!

Que é a tinta plastisol de alta densidade?

Tinta plastisol de alta densidade is a special ink used in serigrafía. It is made from:

- Resina de PVC (un tipo de plástico).

- Plastificantes (oils that make the ink soft).

- Aditivos (to make it thick and strong).

When heated, this ink hardens into a raised design you can feel with your fingers. Brands like Wilflex Quantum HD e FN Ink Xenon Series make popular versions of this ink.

Top 5 Reasons to Use High-Density Plastisol Ink

- 3D Texture: Makes designs pop out like a sticker.

- Bright Colors: Stays vibrant on black shirts and dark fabrics.

- Durabilidade: Won’t crack, fade, or peel after washing.

- Funciona en moitos materiais: Use it on cotton, polyester, bags, mugs, and more.

- Cost-Effective: Saves money because prints last longer.

How to Use High-Density Plastisol Ink

Tools You Need:

- A pantalla con 110-160 mallas.

- A raspador (to push ink through the screen).

- A secador de flash (to heat and harden the ink).

Step-by-Step Guide:

- Prepara a pantalla:

- Use thick emulsion.

- Keep the screen slightly above the fabric.

- Print the Design:

- Layer the ink 2-3 times.

- Use the flash dryer between layers.

- Cure the Ink:

- Heat at 320°F para 45-60 seconds.

Consello profesional: Machines like Equipos de impresión M&R give the best results.

High-Density Plastisol vs. Other Inks

| Tipo de tinta | Mellor para | Peor para |

|---|---|---|

| Plastisol de alta densidade | 3D textures, bold logos | Proxectos ecolóxicos |

| Tinta a base de auga | Soft, light designs | Tecidos escuros |

| Descarga de tinta | Vintage, faded looks | Polyester materials |

Exemplo: Escolle high-density plastisol for hats or shirts with raised logos.

Solución de problemas comúns

| Problema | Solución |

|---|---|

| Rachando | Cure longer at 320°F |

| Color Bleeding | Engadir low-bleed agents |

| Ink Not Sticking | Clean the fabric first |

Tool to Try: Rutland EVO additives help prevent bleeding.

Eco-Friendly High-Density Inks

Newer inks are safer for people and the planet:

- Phthalate-free options (like MagnaColors).

- Segue Oeko-Tex Standard 100 (safe for skin contact).

Consello: Recycle screens and ink containers to reduce waste.

Exemplos do mundo real

- Nike: Uses 3D ink on sports jerseys for texture.

- Adidas: Makes limited-edition shirts with raised logos.

- Artists: Create gallery art with tactile designs.

Event: See new inks at PRINTING United Expo.

Tendencias futuras

- Tintas híbridas: Mix plastisol with water-based inks for softness + durability.

- Digital Tools: Software like AccuRIP helps design precise patterns.

Should You Try High-Density Plastisol Ink?

Yes if you want:

- Designs that stand out.

- Prints that survive 100+ washes.

Start small: Test it on a sample fabric first!

Preguntas frecuentes

Can I use this ink on polyester?

Yes! Add a low-bleed agent to stop colors from spreading.

Can I print fine details?

Use a 160+ mesh screen for thin lines and small text.

How to reduce waste?

Measure ink carefully and reuse screens.