תוֹכֶן הָעִניָנִים

דיו פלסטיזול ידוע בעמידותו ובצבעים מרהיבים בהדפסת בגדים

דיו פלסטיזול לעומת דיו על בסיס מים הוא נהדר שימוש בדיו ידידותיים לסביבה יכול להועיל לסביבה ולתעשיית הדפוס. חלופה בתעשיית הדפוס: מה הכי מתאים לדפוס מסך?

מאמר זה עוזר לך ללמוד על פלסטיזול לעומת דיו על בסיס מים בהדפסת מסך. נשתמש במילים פשוטות. אנו משתמשים ברשימות ובטבלאות. אתה תראה נתונים ועובדות. אנו מקווים שהמדריך הזה יעזור לך לבחור את דיו הדפסת מסך הטוב ביותר לצרכים שלך.

למדריך הזה יש מילים קלות ו ברור רשימות. אנחנו מוסיפים א טבלת נתונים עם עובדות ומספרים. תלמד על דיו ידידותי לסביבה, ה תהליך ריפוי, ו ללא PVC אפשרויות. אנחנו מדברים גם על מותגים כמו Wilflex מציעה מגוון מוצרים המתאימים הן לדיו על בסיס מים והן לדיו פלסטיזול. מהווה בחירה פופולרית בתעשיית הדפוס להפקת הדפסים באיכות גבוהה על בגדים שונים. ו מטסואי. אנו מזכירים כללים כגון אוקו-טקס ורעיונות מ ZDHC ו GOTS.

בואו נתחיל!

1. הקדמה

להדפסת מסך יש אפשרויות דיו רבות. שני דיו עיקריים הם דיו פלסטיזול ו דיו על בסיס מים. לכל דיו יש נקודות טובות ונקודות רעות משלו. אתה יכול לעבוד עם כּוּתנָה אוֹ פּוֹלִיאֶסטֶר. אתה יכול להדפיס על בגדי ספורט או בגדים ידידותיים לסביבה. מדריך זה יראה לך את הדיו הטוב ביותר עבור הצורך שלך.

- דיו פלסטיזול עשוי מ-PVC ומחומרי פלסטיק. הוא סמיך וצריך חום לייבוש.

- דיו על בסיס מים עשוי עם מים. הוא נספג בבד ומרגיש רך.

מדפסות מסך רבות בוחרות דיו פלסטיזול לנוחות שימוש וצבעים בהירים. אחרים בוחרים דיו על בסיס מים כדי להיות אדיבים לכדור הארץ, שקול להשתמש בתוספים ידידותיים לסביבה בתהליך ההדפסה שלך. נשווה את שני הדיו.

2. מבט מהיר: טבלת השוואה

להלן טבלה המציגה עובדות מפתח עבור כל דיו:

| קטגוריית הדיו כוללת צבעי דיו על בסיס מים וגם דיו פלסטיזול ליישומים שונים. | דיו פלסטיזול | דיו על בסיס מים |

|---|---|---|

| שימוש בשוק | 65% של מדפסות משתמשות בו בשביל זה עֲמִידוּת וקלות השימוש. | 28% משתמשים בו, והוא גדל 12% בכל שנה בגלל היותו ידידותית לסביבה. |

| השפעה סביבתית | מכיל PVC ופתלטים. אשפרה מייצרת 3.2 ק"ג CO₂ לכל 1 ק"ג דיו. | 80% טביעת רגל פחמנית נמוכה יותר. זה כן מתכלה אם הוא נטול APEO. |

| עמידות היא קריטית בבחירת דיו לבגדי ספורט. | מחזיק מעמד 50+ כביסות ושומר על צבעים בהירים. | מחזיק 30-50 כביסות. צבעים יכולים לדהות אם לא מטופלים מראש. |

| נוחות (תחושת יד) | מרגיש עבה וגומי. מדורג 2.8/5 עבור רכות. | מרגיש רך וקליל. מדורג 4.5/5 עבור רכות. |

| אטימות על בדים כהים | נותן אטימות 95% ללא עבודה נוספת. | צריך שכבות נוספות עבור אטימות 70%. |

| עֲלוּת | עולה $20–$50 לק"ג. זה זול מלכתחילה. | עולה $30–$70 לק"ג ואולי צריך מייבשים מיוחדים כמו מייבש מסוע. |

| הַתאָמָה | 40% אינם עומדים בכללי REACH של האיחוד האירופי. | 90% להיפגש Oeko-Tex Standard 100. |

| מיקרופלסטיק | משחרר 1,900 סיבים זעירים בכל כביסה, במיוחד על תערובות פוליאסטר. | כמעט ולא משחרר מיקרופלסטיק, בטוח מאוד לטבע. |

| ייבוש / אשפרה | זקוק לחום ב-320 מעלות צלזיוס למשך 60-90 שניות. | יבש באוויר תוך 15-30 דקות או ארפא ב-250°F למשך 2-3 דקות. |

| תיאור מקרה | א מותג בגדי ספורט חסך 25% בעלויות דיו עם פלסטיזול. | א חברת הלבשה אקולוגית הוריד את עלויות הפסולת ב-40% עם דיו על בסיס מים. |

3. מהו דיו פלסטיזול?

דיו פלסטיזול הוא דיו קלאסי בהדפסת מסך. הוא משתמש ב-PVC ובחומרי פלסטיק. להלן נקודות המפתח:

- עבה וצמיג: הוא נשאר סמיך עד שהוא מתרפא בחום.

- אטימות גבוהה: זה נותן צבעים בהירים ונועזים אפילו על בדים כהים.

- קל לשימוש: זה סלחן לטעויות קטנות. זה עושה את זה טוב למתחילים.

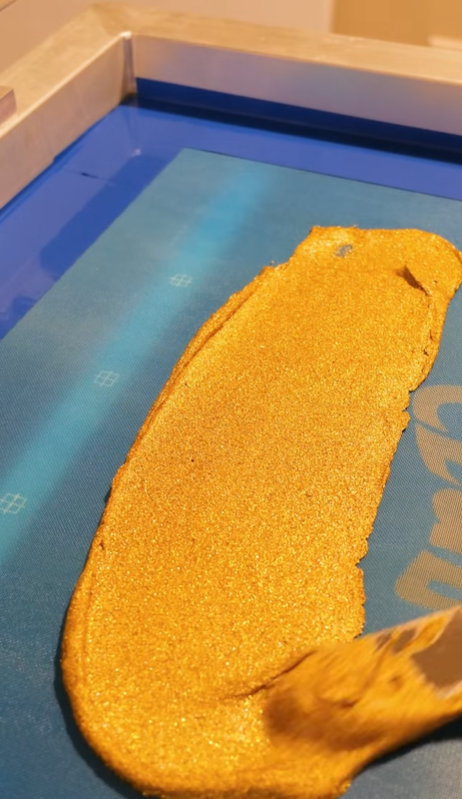

- צבעים מרהיבים: אתה מקבל צבעים בהירים, ואתה יכול אפילו להוסיף אפקטים מיוחדים כמו נצנצים.

- עֲמִידוּת: זה מחזיק יותר מ-50 כביסות. זה לא דוהה מהר.

עם זאת, יש כמה חסרונות:

- תחושת גומי: העיצוב המודפס עשוי להרגיש עבה ונוקשה.

- לא ידידותי לסביבה: יש בו PVC ופתלטים. זו בעיה עבור כדור הארץ.

- טמפרטורת ריפוי גבוהה: הוא זקוק לחום גבוה (320°F) למשך 60-90 שניות כאשר עובדים עם הדפס פלסטיזול. זה יכול לצרוך הרבה אנרגיה.

דיו פלסטיזול עובד היטב עבור בגדי ספורט. זה עובד הכי טוב על בדים כהים וכשאתה רוצה הדפסים בהירים וחזקים. מדפסות רבות אוהבות מותגים כמו וילפלקס ו מטסואי עבור הדיו הזה.

4. מהו דיו על בסיס מים?

דיו על בסיס מים הוא סוג חדש יותר של דיו. הוא משתמש בעיקר במים בתור המוביל שלו. לדיו הזה יש הרבה נקודות טובות:

- תחושה רכה: זה נספג בבד. ההדפס מרגיש קל וכמעט לא מורגש.

- ידידותי לסביבה: זה כן מתכלה. זה גם כן ללא PVC ודל בכימיקלים מזיקים.

- לנשימה: הדיו נותן לבד לנשום. זה טוב לבגדים כמו בגדי תינוקות וביגוד מכותנה אורגנית.

- מראה חלק: זה נותן מראה וינטג' רך יותר להדפס.

אבל יש כאלה אתגרים:

- זמן ייבוש ארוך יותר: זה לוקח 15-30 דקות לייבוש באוויר.

- אטימות נמוכה יותר: בבדים כהים, ייתכן שתצטרך שכבות נוספות וטיפול מקדים.

- דרושה מיומנות: זה יכול לסתום מסכים אם לא משתמשים בו היטב. אתה צריך יותר מיומנות כדי לעבוד עם זה.

למי שאכפת לו מכדור הארץ, דיו על בסיס מים היא הבחירה. זה פופולרי בקרב מותגים אקולוגיים המשתמשים כותנה אורגנית ובדים טבעיים אחרים. זה גם עונה על כללים כמו Oeko-Tex Standard 100 ו ZDHC הנחיות.

5. השוואה ראש בראש

כאן אנחנו משווים פלסטיזול לעומת דיו על בסיס מים זֶה בְּצַד זֶה. זה יעזור לך לראות מה הכי חשוב לך.

א. עמידות ויכולת כביסה

- דיו פלסטיזול

- מחזיק מעל 50 כביסות.

- צבעים אינם דוהים בקלות.

- הטוב ביותר לשימוש רב.

- דיו על בסיס מים

- מחזיק 30-50 כביסות.

- צבעים עלולים לדהות אם הדיו אינו עובר טיפול מוקדם.

ב. נוחות ותחושה

- דיו פלסטיזול

- נותן תחושה עבה וגומי.

- עלול להרגיש כבד על כותנה.

- דיו על בסיס מים

- מרגיש רך וקליל.

- נותן לבד להרגיש טבעי.

ג. השפעה על הסביבה

- דיו פלסטיזול

- מכיל PVC ופתלטים.

- משחרר מיקרופלסטיק ויש לו פליטת פחמן גבוהה.

- דיו על בסיס מים

- האם ידידותית לסביבה.

- בעל טביעת רגל פחמנית נמוכה והוא כמעט נקי ממיקרו-פלסטיק.

ד. ניתוח עלויות

- דיו פלסטיזול

- עולה פחות ב-$20–$50 לק"ג.

- עלות דיו נמוכה יותר אך משתמשת יותר באנרגיה לריפוי.

- דיו על בסיס מים

- עולה $30–$70 לק"ג.

- חייבים לקנות מייבשים מיוחדים לפעמים.

ה. מקרי השימוש הטובים ביותר

- דיו פלסטיזול

- אידיאלי לבגדי ספורט נועזים.

- טוב לבדים כהים.

- משמש בהזמנות בנפח גבוה.

- דיו על בסיס מים

- הטוב ביותר עבור מותגים ידידותיים לסביבה.

- מתאים לכותנה אורגנית ולבגדי תינוקות.

- אידיאלי עבור בדים קלים ולבוש מזדמן.

6. גורמי החלטה: איך לבחור

כאשר אתה בוחר דיו, חשבו על אלה 5 נקודות שכדאי לקחת בחשבון בעת בחירת צבעי דיו לפרויקטים של הדפסת בגדים.:

- סוג בד:

- בדים כהים עשויים להשתפר דיו פלסטיזול.

- בדים קלים וכותנה אורגנית מסתדרים בצורה הטובה ביותר דיו על בסיס מים.

- הדפס אריכות ימים:

- אם אתה צריך הדפסים שמחזיקות מעמד הרבה כביסות, דיו פלסטיזול היא הבחירה.

- אם רכות היא המפתח, נסה דיו על בסיס מים.

- תַקצִיב:

- דיו פלסטיזול זול יותר מראש.

- דיו על בסיס מים עשוי לעלות יותר אך חוסך בזבוז ובעלויות אנרגיה לאורך זמן.

- רמת מיומנות:

- דיו פלסטיזול עובד היטב למתחילים.

- דיו על בסיס מים מתאים למי שיש יותר ניסיון.

- כללים סביבתיים:

- דע את הכללים עבור השוק שלך.

- דיו על בסיס מים פוגש Oeko-Tex Standard 100 ו ZDHC.

- אלה הם המפתח עבור מותגים ידידותיים לסביבה.

7. טעויות נפוצות שיש להימנע מהן

הנה כמה רשימות של טעויות שאסור לעשות:

- עבור דיו פלסטיזול:

- אל תשתמש בו לבגדי תינוקות. יש בו כימיקלים מזיקים.

- אל תתרפא. זה יכול לגרום לסדקים בהדפסה.

- אל תתעלם מעלות האנרגיה הגבוהה.

- עבור דיו על בסיס מים:

- אל תדלגו על הטיפול המקדים בבדים כהים.

- אל תיתן לדיו להתייבש זמן רב מדי על המסך שלך.

- אל תשתמש בו אם אתה רק לומד; זה צריך טיפול נוסף.

עדיף לתכנן את העבודה שלך ולעקוב אחר ההוראות עבור כל דיו.

8. שאלות נפוצות

הנה כמה שאלות נפוצות שיכול לעזור לך לבחור:

האם אני יכול לערבב פלסטיזול ודיו על בסיס מים?

לא, לא לערבב. הם עובדים הכי טוב לבד. ערבוב עלול לגרום להדפסים גרועים, במיוחד כאשר משתמשים בפיגמנטים אטומים שאינם מתמזגים היטב.

איזה דיו טוב לבדים נמתחים?

דיו פלסטיזול עובד היטב על בגדי ספורט נמתחים.

האם דיו על בסיס מים באמת ידידותי לסביבה?

כֵּן. זה כן מתכלה ועומד בחוקים כמו Oeko-Tex Standard 100.

האם ניתן להדפיס על כותנה אורגנית עם דיו על בסיס מים?

כן, דיו על בסיס מים הוא הטוב ביותר עבור סיבים טבעיים כמו כותנה אורגנית.

9. תיאורי מקרה

בואו נסתכל על כמה סיפורים אמיתיים:

- נרתיק למותג בגדי ספורט:

מותג בגדי ספורט בשימוש דיו פלסטיזול. הם חסכו 25% בעלות הדיו שלהם. ההדפסים החזיקו מעמד היטב גם בשימוש רב. זה מראה דיו פלסטיזול עובד נהדר עבור הזמנות בנפח גבוה ובדים כהים. - מארז חברת אקו-פרל:

חברת הלבשה אקולוגית עברה ל דיו על בסיס מים. הם הורידו את עלות פינוי הפסולת שלהם ב-40%. ההדפס הרך היה אהוב על הלקוחות שלהם. זה מראה דיו על בסיס מים היא בחירה חזקה עבור מותגים ידידותיים לסביבה.

10. מסקנה ומחשבות אחרונות

הסתכלנו פלסטיזול לעומת דיו על בסיס מים. להלן הנקודות העיקריות:

- דיו פלסטיזול:

- יתרונות: צבעים בהירים, אטימות גבוהה, קל לשימוש, טוב לבגדי ספורט ובדים כהים.

- חסרונות: תחושה עבה, אנרגיה גבוהה לריפוי, לא ידידותית לסביבה.

- דיו על בסיס מים:

- יתרונות: תחושה רכה, ידידותית לסביבה, מראה טבעי, טוב לבדים קלים וכותנה אורגנית.

- חסרונות: זמן ייבוש ארוך יותר, אטימות נמוכה יותר בבדים כהים, נדרשת מיומנות רבה יותר.

איך לבחור?

חשבו על הבד שלכם, על אורך החיים של ההדפס, על התקציב, על המיומנות ועל הכללים. אם אתה עובד עם בגדי ספורט או זקוק להדפסים נועזים בעלות נמוכה, נסה צבעי פלסטיזול להדפסת מסך. דיו פלסטיזול. אבל אם אכפת לך מהאדמה ואת רוצה הדפס רך לכותנה אורגנית, בחרי דיו על בסיס מים.

התראת מגמה: מעצבים מסוימים אוהבים להשתמש בדיו היברידיים. אלה מנסים להצטרף לנקודות הטובות של שני סוגי הדיו. הם יכולים להיות בחירה טובה אם אתה רוצה לשמור על התחושה הבהירה ולהוריד את הפגיעה בכדור הארץ שלנו.

כשאתה בוחר, השתמש בעובדות שהצגנו בטבלה שלנו. דע את זה פלסטיזול לעומת דיו על בסיס מים זה לא רק על עלות. זה בערך עֲמִידוּת, נוֹחוּת, סְבִיבָה, ו קלות השימוש.

פעל תמיד לפי הוראות ערכת הדפסת המסך. השתמש בהגדרות הנכונות במייבש או המסוע שלך. נקה את הכלים שלך היטב. טיפול זה עוזר לך לעשות את דיו הדפסת מסך הטוב ביותר אַחֲרוֹן.

סיכום מהיר: נקודות מפתח ופעולות

- הכר את הדיו שלך:

- דיו פלסטיזול הוא עבה. הוא משמש להדפסים נועזים ובהירים.

- דיו על בסיס מים מרגיש רך. זה טוב לבדים טבעיים ולאדמה.

- ראה את הנתונים:

- השתמש בטבלה שלנו כדי להשוות עובדות כמו עמידות כביסה, עלות וזמן ריפוי.

- שקול את הכללים:

- מותגים חייבים לעקוב Oeko-Tex Standard 100 ו ZDHC.

- מותגי אקו בוחרים על בסיס מים כדי לעמוד בכללים הללו.

- שלבי פעולה:

- בדוק את סוג הבד ואת צרכי ההדפסה שלך.

- תחליט אם אתה רוצה א תחושה עבה או א תחושה רכה.

- איזון התקציב שלך עם עלות דיו.

- תרגל תחילה עם סוג אחד אם אתה חדש.

- בצע את צעדי הטיפול כדי למנוע טעויות.

- השתמש במותגים טובים:

- חפש דיו מ וילפלקס ו מטסואי.

- קרא ביקורות וספרי הדרכה כדי לדעת יותר.

מחשבות אחרונות

אנו מקווים שמדריך זה יעזור לך לנקות את הערפול של אפשרויות הדיו בהדפסת מסך. הפרויקט שלך עשוי להיות בבגדי ספורט או קווים ידידותיים לסביבה. השתמש במדריך זה כדי להתאים את הדיו המתאים לצורך שלך. העובדות מראות זאת דיו פלסטיזול הוא חזק וחסכוני. דיו על בסיס מים הוא רך, ידידותי לסביבה וטוב יותר לטבע.

הדפס היטב. הדפס חכם. ובחר את דיו הדפסת מסך הטוב ביותר לאמנות ולעסק שלך. תהנה מהכיף של הדפסת מסך וצור הדפסים יפים שיחזיקו מעמד.

תודה שקראת את המדריך הזה. אנו מאחלים לך את הטוב ביותר בעבודת הדפסת המסך שלך!