Sadržaj

Razumijevanje tinti za sitotisak: vrste, savjeti i tehnike

Boje za sitotisak su zabava i važnoOni čine našu umjetnost svijetlom i snažnom. U ovom ćemo članku saznati više o bojama za sitotisak. Razgovarat ćemo o vrste, savjeti, i tehnikeKoristit ćemo tablicu i popise. Također ćemo koristiti jednostavne riječi kako bi bilo lako čitati svima[^1].

Što su tinte za sitotisak?

Boje za sitotisak su Odaberite posebne boje u tinti za blokovski tisak za jedinstvene dizajne.Idu na ekran, zatim na majicu ili znak. Tinta prikazuje našu umjetnost tako da izgleda lijepo i hladnoVrsta tinte koju odaberete može promijeniti izgled i vijek trajanja vašeg rada. Također mijenja koliko je jednostavno ispisivati. Korištenje prave tinte dat će vam svijetao boje i učinite da vaš otisak traje dugo.

Vrste boja za sitotisak

Postoji mnogo vrsta tinte. Svaka ima svoje profesionalci i kontraEvo glavnih vrsta:

1. Plastisolne tinte

- Prednosti:

- Snažno i vibrantan boje.

- Lako za početnici.

- Izdržljiv na mnogim tkaninama.

- Protiv:

- Za sušenje im je potrebna toplina.

- Imaju PVC.

Najbolje za:

- Majice kratkih rukava i dizajni visoke neprozirnosti.

- Mnoge trgovine koriste ove tinte jer su popularan[^2].

2. Tinte na bazi vode

- Prednosti:

- Više ekološki prihvatljiv.

- Daju a mekan izgled.

- Proširili su se u tkaninu.

- Protiv:

- Brzo se suše.

- Zahtijevaju više vještine.

Najbolje za:

- Održivi tisak i lagane tkanine.

- Ljudi koji brinu o Zemlji vole ove tinte[^3].

3. Tinte za pražnjenje

- Ove tinte ukloniti boja u tamnim tkaninama.

- Daju a berba izgled.

- Najbolje za:

- Dizajni na pamuku s daškom stare škole.

4. Specijalne tinte

Postoji mnogo zanimljivih posebnih tinti:

- UV-sušljive tinte:

- Brzo se suši kada je izložen UV svjetlu.

- Troše manje energije.

- Puff tinte:

- Dobiti napuhan kada se zagrijavaju.

- Daju 3D dodir.

- Metalik / tinte koje svijetle u mraku:

- Dodaju posebnu kvalitetu tisku na odjeći. sjaj ili sjaj otiscima.

Ove tinte mogu učiniti vaš rad isticati se s jedinstvenim izgledom.

Kako odabrati pravu tintu

Važno je odabrati pravu tintu. Evo nekoliko načina za odabir najbolje tinte:

- Vrsta tkanine:

- Pamuk, poliester ili mješavine zahtijevaju različite tinte.

- Završiti:

- Želite li a sjajni pogled, jedan mat pogled, ili teksturirano završiti?

- Utjecaj na klimu:

- Ako volite našu Zemlju, potražite tinte bez PVC-a ili bez otapala.

- Oprema:

- Imate li termo prešu, sušilicu ili UV lampu?

Savjeti za nanošenje tinte za sitotisak

Za dobivanje izvrsnih otisaka, slijedite ove savjete:

1. Priprema prije tiska

- Očistite ekran.

- Uklonite prašinu i staru tintu.

- Premazati emulzijom.

- To vam pomaže da napravite jasan dizajn.

- Probni ispis.

- Napravite mali test prije velikog ispisa.

2. Miješanje i konzistencija tinte

- Dobro promiješajte tintu.

- Dobro miješanje daje glatku tintu.

- Kontrolirajte viskoznost**

- Po potrebi koristite reduktore ili usporivače.

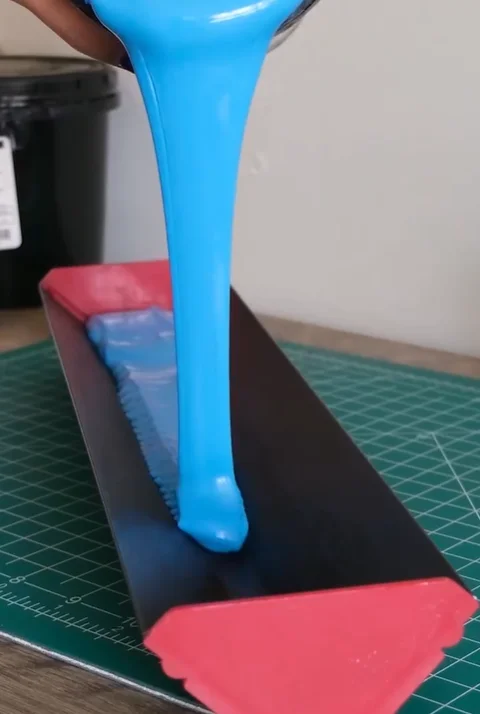

3. Tehnike brisača

- Držite brisač pod dobrim kutom.

- Koristiti pravi pritisak za glatku tintu.

- Praksa pritisak brisača kako bi se dobio uredan otisak.

4. Metode sušenja

- Toplinska preša:

- Odlično za plastisol.

- Pokretna sušilica:

- Brzo suši mnoge otiske.

- Brzo stvrdnjavanje:

- Prilikom ispisa dodatnih boja koristite kratke nalete topline (bljeskalično sušenje).

Ovi koraci pomažu da se tinta dobro zalijepi i traje dugo.

Napredne tehnike za bolje ispise

Da bi vaši otisci izgledali još bolje, isprobajte ove trikove:

1. Višebojni ispis

- Koristiti registarske oznake tako da svaka boja odgovara.

- Napravite podnožje sloj.

- Koristiti bljeskaličko stvrdnjavanje između slojeva.

2. Simulirani proces ispisa

- Koristiti polutonovi za glatko miješanje boja.

- Ovo funkcionira za fotorealistične dizajne.

3. Efekti gradijenta i miješanja

- Probati mokro na mokro tisak.

- Koristiti split-fountain tehnike.

- Ovo uzrokuje blage promjene boja.

4. Broj sita i emulzijski premaz

- Koristite kaznu broj mreža (230–305) za oštre detalje.

- Emulzijski premaz kvaliteta je ključna za čiste otiske.

Uobičajeni problemi s tintom za sitotisak i rješenja

Čak i odrasli mogu imati problema s ispisom. Evo nekih uobičajenih problema i jednostavnih rješenja:

1. Krvarenje tinte

- Problem: Tinta prelazi svoj rub.

- Uzrok: Previsok ili nizak pritisak broj mreža.

- Popraviti:

- Koristite veći broj oka.

- Prilagodite pritisak brisača.

2. Loše prianjanje

- Problem: Tinta se ne lijepi dobro, posebno kod tinti niske neprozirnosti.

- Uzrok: Tinta se ne suši pravilno.

- Popraviti:

- Provjerite izvor topline i vrijeme.

- Pobrinite se da lijek bunar s tintom.

3. Začepljenje zaslona

- Problem: Tinta se nakuplja na zaslonu.

- Uzrok: Osušena tinta blokira zaslon.

- Popraviti:

- Odmah očistite ekran.

- Koristite otvarač ekrana.

4. Rupice ili nedosljednosti

- Problem: Male rupice ili mrlje na otiscima.

- Uzrok: Prašina ili problemi u vašem emulzijskom premazu.

- Popraviti:

- Prije upotrebe temeljito očistite ekran.

- Ponovno premažite sito svježom emulzijom.

Ekološki prihvatljive prakse sitotiska

Mnogi tiskari sada brinu o našem planetu. Evo ih ekološki prihvatljiv savjeti:

Tinte na bazi vode u odnosu na plastisol tinte

- Tinte na bazi vode su zelena.

- Danas ih koriste 40% pisači.

- Plastisol tinte jaki su, ali ne tako zeleni.

Recikliranje i čišćenje

- Reciklirajte korištene tinte.

- Koristite ekološki prihvatljiva sredstva za čišćenje.

- Potražite tinte koje su Bez PVC-a.

Certifikati

- Tražiti REACH EU-a i slične oznake.

- Certificirane tinte pomažu vam da ostanete sigurni i ekološki osviješteni.

Podaci i statistike o bojama za sitotisak

Donja tablica prikazuje neke korisne podatke. Pomaže nam da vidimo trendove u industriji i ključne činjenice.

| Kategorija | Donja tablica prikazuje neke korisne podatke o bojama za sitotisak na tkanini. | Izvor | Relevantnost |

|---|---|---|---|

| Trendovi na tržištu | Tržište raste po složenoj godišnjoj stopi rasta od 4,81 TP4T (2023. – 2030.) | Istraživanje Grand View (2023) | Prikazuje više ljudi koji tiskaju umjetnine. |

| Potrošnja tinte | 65% na tržištu koristi plastisolne tinte | Smithersovo Pira izvješće (2022.) | Plastisol je vrlo čest. |

| Održivost | 40% pisači koriste tinte na bazi vode ili eko-solventne tinte | FESPA Global Print Expo (2023.) | Sve više ljudi bira zelene tinte. |

| Učinkovitost stvrdnjavanja | UV tinte smanjuju potrošnju energije kod 30% | RadTech UV studija (2021.) | UV tinte pomažu Zemlji. |

| Studija slučaja | „EcoThreads“ smanjuje otpad za 50% s tintama za ispuštanje na organskom pamuku | Održivi brendovi (2023.) | Pokazuje kako su tinte za izbijanje dobre za zelene radove. |

| Uobičajeni problemi | 25% nedostataka dolazi od pogrešnog broja mreža | ScreenPrinting.com (2023.) | Dobar broj mrežica je vrlo važan. |

| Analiza troškova | Tinte na bazi vode koštaju 20% više, ali štede na naknadama za otpad | Cijena tinte Wilflex (2023.) | Usporedite troškove s dugoročnom uštedom. |

| Statistike izdržljivosti | Pravilno osušeni plastisol traje 50+ pranja; loše osušavanje pogoršava otiske 70% | Međunarodni laboratorij za premaze (2022.) | Sušenje je ključno za dugotrajne otiske. |

| Studija slučaja | „PrintPros“ je povećao izlaz za 35% koristeći pametne sustave za miješanje tinte | Časopis Printwear (2023.) | Tehnologija vam može pomoći s otiscima. |

| Preferencije potrošača | 60% kupaca voli otiske mekane rukom izrađene tintom na bazi vode | Anketa potrošača SGIA-e (2023.) | Za mekši osjećaj koristite tinte na bazi vode. |

| Utjecaj opreme | Korištenje veličine mrežica od 230 do 305 pomaže u urednom simuliranom procesu ispisa | Tehnički vodič Ryoneta (2023.) | Broj mrežica je važan u likovnoj umjetnosti. |

| Regulatorni podaci | Tinte bez PVC-a zadovoljavaju standarde EU REACH-a | Baza podataka o propisima EU o kemikalijama | Slijedite pravila i ostanite sigurni. |

| Studija slučaja | Kiwo hibridne tinte smanjuju začepljenje sita kod 90% ispisa velikih količina | Kiwo priča o uspjehu (2023.) | Hibridne tinte dobro funkcioniraju za velike narudžbe. |

| Perivost | Tinte za izbacivanje zadržavaju boju 95% nakon 30 pranja na pamuku | Jacquardovo testiranje (2022.) | Dobro za trajnu boju. |

| Utjecaj treninga | Obučeni tiskari imaju 50% manje pogrešaka povezanih s korištenjem tinte | TISAK United Alliance (2023.) | Trening je vrlo koristan. |

| Nišne aplikacije | Vodljive tinte se koriste u 15% kompletima za nošenje tehnologije | Izvješće IDTechEx-a (2023.) | Za tehnološke ispise koristite posebne tinte. |

| Eko-certifikati | SGP-certificirani pisači godišnje uštede 1 TP5 T5 tisuća dolara uz manje otpada i energije | Studija slučaja SGP-a (2023.) | Certifikati štede novac i resurse. |

Praktični koraci za postizanje najboljih rezultata

Evo jasnih i jednostavnih koraka koje treba slijediti za odlično ispis:

- Pripremite svoj rad

- Očistite svoje ekrane.

- Za jasan dizajn koristite svježu emulziju.

- Pomiješajte svoju tintu

- Dobro promiješajte dok tinta ne postane glatka.

- Ne dopustite da se tinta osuši.

- Ispisujte s dobrim gumenim špatulom

- Držite brisač pod kutom.

- Pritisnite desnom tipkom pritisak brisača.

- Za uredan završetak koristite ravnomjerne poteze.

- Osušite svoju tintu

- Koristite termo prešu ili sušilicu.

- Provjerite svaki otisak je li se osušio kako biste osigurali neprozirnost boja.

- Pregled i ispravljanje problema

- Potražite curenje tinte ili rupice od iglica.

- Popravite broj mrežica ili očistite sita.

Ovi koraci vam pomažu u izradi otisaka koji su dugotrajan i svijetao.

Savjeti za korištenje specijalnih tinti

Posebne tinte mogu učiniti vašu umjetnost jedinstvenom. Evo nekoliko jednostavnih savjeta:

- UV-sušljive tinte:

- Za brzo sušenje tinte koristite UV lampu.

- Štede energiju korištenjem manje snage za 30%[^2].

- Puff tinte:

- Napuhnu se kad ih zagriješ.

- Daju zabavan, 3D izgled.

- Metalik i tinte koje svijetle u mraku:

- Koristite ove tinte za poseban efekt.

- Oni dodaju sjaj ili iskru vašem dizajnu.

Kada koristite ove tinte, slijedite iste korake: miješajte, ispisujte i sušite.

Detaljan pogled na napredne tehnike

Napredne tehnike mogu ukloniti vaš otisak iz dobro do nevjerojatnoPogledajmo pobliže.

Višebojni ispis

- Planirajte unaprijed:

- Napravite plan sa svakom bojom.

- Koristite registracijske oznake:

- Ove oznake pomažu u poravnavanju boja.

- Podni sloj:

- Prvo isprintajte svijetlu boju, a zatim dodajte ostale boje.

- Brzo stvrdnjavanje:

- Osušite između slojeva kako biste spriječili pomicanje tinte[^2].

Simulirani proces ispisa

- Stapanje polutonova:

- Koristite sitne točkice za miješanje boja.

- Korak po korak:

- Ispisujte slojeve polako.

- Gledajte kako se boje miješaju.

Efekti gradijenta i miješanja

- Tehnika mokro na mokro:

- Ispisujte boje na mokroj tinti kako biste postigli glatko prelijevanje.

- Tehnika split-fountain-a:

- Koristite jednu gumenu špatu s dvije boje.

Ove tehnike mogu učiniti da vaši otisci izgledaju kao prava umjetnost.

Učenje i osposobljavanje

Korisno je učiti od stručnjaka. Trening može smanjiti vaše pogreške za 50%[^2]. Evo načina za poboljšanje:

- Online tutorijali:

- Pronađite videozapise i jednostavne vodiče.

- Radionice:

- Pridružite se tečaju u vašoj blizini.

- Praksa:

- Što više ispisujete, to bolje dobivate.

Pokušajte naučiti o broj mreža i emulzijski premazIsprobajte drugačije tehnike čišćenja gumenim valjkomSvaka vježba vas čini boljim pisačem, posebno kada koristite Speedball tinte za tkanine.

Često postavljana pitanja o bojama za sitotisak

U nastavku su neka uobičajena pitanja i odgovori:

Mogu li miješati plastisolne i tinte na bazi vode?

Ne, njihovo miješanje može uzrokovati probleme s vašim ispisom.

Koliko pranja traju otisci?

Dobro osušeni plastisol može izdržati 50+ pranja. Ali ako se ne osuši, otisak se može djelomično odlijepiti.

Koja je najbolja tinta za rastezljive tkanine?

Tinte na bazi vode najbolje funkcioniraju za mekane, rastezljive tkanine.

Hoće li UV-sušive tinte uštedjeti energiju?

Da, troše 30% manje energije.

Koja je tinta najbolja za zeleni projekt?

Tinte na bazi vode, tinte s ispuštanjem ili specijalne eko tinte su dobar izbor.

Sažetak: Ključne točke koje treba zapamtiti

- Tinte za sitotisak učinimo našu umjetnost sjajnom.

- Mnogo ih je vrstePlastisol, na bazi vode, ispuštanje i specijalni.

- The desna tinta ovisi o vašoj tkanini, završnoj obradi i ekološkim potrebama.

- Koristi dobro tehnike čišćenja gumenim valjkom i broj mreža za savršene otiske.

- Vježba i trening pomoći će vam da dobro koristite tinte.

- Koristiti ekološki prihvatljiv tinte za svjetliju, zelenu budućnost.

Radna tablica za brzo snalaženje

Evo tablice za brzo pretraživanje koja će vam pomoći da zapamtite važne činjenice:

| Vrsta / Faktor | Ključna točka | Savjet |

|---|---|---|

| Plastisol tinta | Uobičajeno i vibrantanPotrebno je toplinsko sušenje. | Koristite za majice i smjelu umjetnost. |

| Tinta na bazi vode | Ekološki prihvatljiv i mekano. Brzo se suši. | Najbolje za lagane tkanine, zeleni rad. |

| Tinta za pražnjenje | Uklanja boju za vintage izgled. | Izvrsno za pamuk sa starinskim štihom. |

| Specijalna tinta | UV stvrdnjava se, puf, metalik, sjaji. Koristiti po potrebi. | Dodaje posebne efekte ispisima. |

| Broj mreža | 230–305 za detalje. | Za tanke otiske koristite finu mrežicu. |

| Tlak brisača | Uravnoteženi pritisak daje ravnomjernu tintu. | Vježbajte za uredan završetak. |

| Flash stvrdnjavanje | Brzi toplinski udari za dodatne slojeve. | Koristi se za višebojne ispise. |

| Emulzijski premaz | Održava detalje oštrima. | Čisto sito pomaže da se emulzija zalijepi. |

Zaključak

Boje za sitotisak su srce odličnih otisaka. S mnogim vrste tinte, možete odabrati što vam najbolje odgovara. Slijedeći ove jednostavne savjete, možete stvoriti umjetnost koja je svijetao, dugotrajan, i prekrasnoNe zaboravite koristiti dobro broj mreža, desno pritisak brisačai učinite bljeskaličko stvrdnjavanje u pravo vrijeme. Vježbajte, učite i isprobavajte nove alate poput Wilflex, Speedball, i Žakard tinte. Ovi koraci pomažu da svaki ispis bude vaš najbolji rad.

Svaki korak, od predprese do sušenja, dodaje poseban dodir za svoj rad. Koristite ekološki prihvatljive tinte kako biste se brinuli o našoj Zemlji. Neka vaši otisci zablistaju bojom i životom. Ako slijedite naše savjete i provjerite činjenice poput tržišni trend i uobičajeni problemi, vaši će otisci svakim danom biti sve bolji.

Ostanite znatiželjni i nastavite učiti. Postoji mnogo načina da svoju umjetnost sitotiska učinite još zabavnijom. Koristite obuku, pokušajte napredne tehnikei čitajte o specijalne tinte proširiti svoje vještine. S vremenom i pažnjom, izrađivat ćete otiske koje će mnogi voljeti.

Hvala vam što ste čitali. Nadamo se da sada znate više o boje za sitotisakStvori svoju umjetnost živopisan i trajanSretan ispis!