Table of Contents

Plastisol Ink: Why It’s the Best Choice for Screen Printing

Meta Description: Learn why plastisol ink is the top pick for bright, long-lasting prints on clothes, labels, and more. Compare it to other inks and see how to use it right.

What Is Plastisol Ink?

Plastisol ink is a special ink used in screen printing. It is made from PVC resin and plasticizers. This mix makes it thick and sticky. People love it because it works great on fabrics like t-shirts, hats, and bags.

Did you know? Over 70% of screen printers use plastisol ink!

5 Big Reasons to Choose Plastisol Ink

1. Covers Dark Fabrics Perfectly

- Plastisol ink is opaque (not see-through).

- It stays bright on black or dark-colored fabrics (like band t-shirts).

- Water-based inks can’t do this!

2. Lasts a Long Time

- Prints stay bright after many washes.

- Great for work clothes or outdoor banners (resists sun and rain).

- Colorfastness means colors don’t fade.

3. Easy to Use

- No need to pretreat fabrics (unlike water-based inks).

- Works on cotton, polyester, and blends.

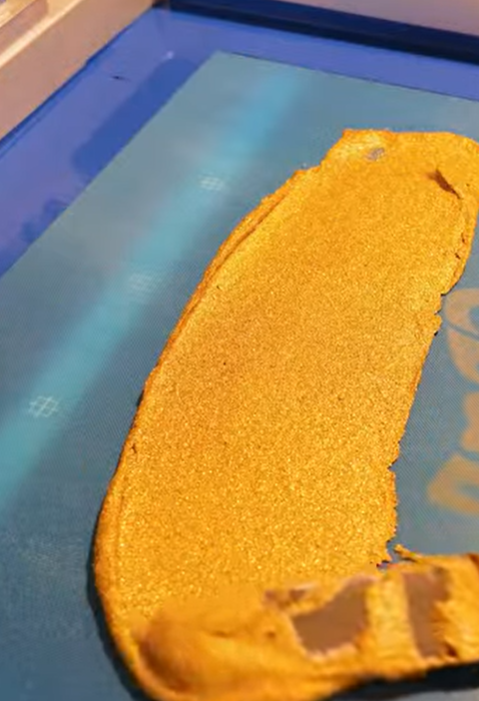

4. Fun Special Effects

- Add glitter, puff, or metallic finishes.

- Use Rutland Magnaprint for 3D textures.

5. Great for Big Jobs

- Stays wet in screens longer (no drying during printing).

- Perfect for bulk orders (like school event shirts).

Plastisol vs. Other Inks: What’s Better?

| Ink Type | Best For | Not Good For |

|---|---|---|

| Plastisol | Dark fabrics, bulk jobs | Eco-friendly projects |

| Water-Based | Soft feel, eco-friendly | Dark fabrics, long washes |

| Discharge | Vintage looks on cotton | Synthetic fabrics |

| Eco-Solvent | Synthetic materials | Low budgets, quick jobs |

Is Plastisol Ink Bad for the Earth?

Old plastisol inks had chemicals called phthalates (bad for the environment). Now, companies make safer options:

- Phthalate-free inks: Try Union Ink ECO Series or Wilflex Epic.

- Low-VOC inks: Matsui and Green Galaxy are greener choices.

Look for: Oeko-Tex Standard 100 certification (means safe for skin).

How to Use Plastisol Ink: 4 Easy Steps

- Cure It Right

- Heat to 300–330°F for 60–90 seconds.

- Use a M&R dryer for even heat.

- Pick the Right Screen

- Use 110–160 mesh for details.

- Use 200+ mesh for thin inks.

- Add Special Mixes

- Soft-hand additive makes prints comfy.

- Silicone helps prints stretch.

- Avoid Mistakes

- Don’t add too much water (over-thinning).

- Test print first!

Where to Use Plastisol Ink

Clothes

- Gym shirts, hoodies, and event tees (like Gildan or Hanes brands).

Promotional Items

- Tote bags, silicone wristbands, and mousepads.

Industrial Uses

- Car decals, PVC labels, and durable tags (meets ASTM D4366 standard).

FAQs

Is plastisol ink safe for baby clothes?

Only if it’s phthalate-free (check the label!).

Can I print on nylon?

No—plastisol doesn’t stick well to nylon or silk.

Will plastisol crack?

Only if you don’t cure it right! Follow heat guidelines.