Welcome! This guide explores how tusze specjalistyczne enhance textile printing with expert insights from Industry Experience Ltd.

Whether you’re a beginner or a seasoned printer, we’ll break down the latest in sitodruk, eco-friendly solutions, and advanced techniques.

Spis treści

1. Types of Specialty Inks

Specialty inks go beyond standard options, offering unique textures, finishes, and durability. Key categories include:

A. Plastisol Inks

- Durable & vibrant, ideal for apparel.

- Examples:

- Extra Green Plastisol Ink (eco-friendly)

- Extra Black Plastisol Ink (high opacity)

- Tusz Puff Plastisol (3D texture)

B. Water-Based Inks

- Soft feel, eco-friendly.

- Lower VOC emissions, great for detailed designs.

C. UV-Curable Inks

- Fast-drying, works on rigid substrates (glass, metal).

- Energy-efficient with LED curing.

D. Special Effects Inks

- Metallic Finishes: Shimmering results.

- Glow-in-the-Dark: Perfect for novelty items.

- Sublimation Inks: Vibrant, dye-based prints.

Quick Comparison Table

| Rodzaj tuszu | Najlepszy dla | Key Benefit |

|---|---|---|

| Plastizol | Apparel, durability | High opacity, long-lasting |

| Na bazie wody | Projekty przyjazne dla środowiska | Soft hand feel |

| UV-Curable | Hard surfaces | Instant curing |

| Puff/High-Density | Textured designs | 3D effect |

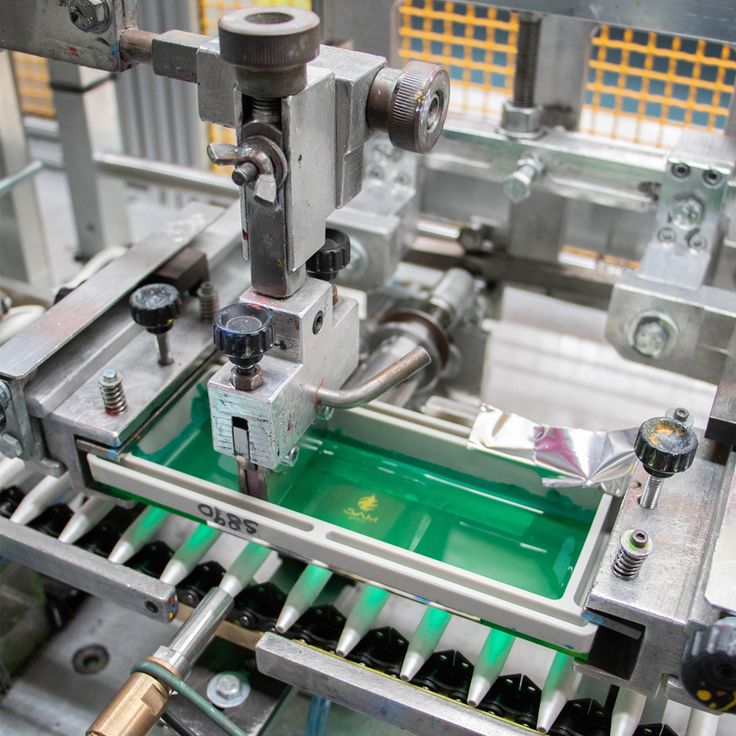

2. Screen Printing Techniques

Master these methods for flawless prints:

A. Setup

- Mesh Count Selection: Higher for fine details (~230 mesh), lower for bold prints (~110 mesh).

- Screen Emulsion: Używać Saati Emulsions lub Ulano Emulsion Removers for clean screens.

B. Printing Process

- Ciśnienie ściągaczki: Adjust for even ink deposit.

- Flash Curing: Partially dry layers before adding colors.

- Registration Accuracy: Align multi-color designs precisely.

C. Troubleshooting

- Clogged Screens? Używać Screen Reclaiming techniques.

- Ink Not Sticking? Apply Platen Adhesives lub Plasma Treatment.

3. Sustainability in Screen Printing

Eco-friendly practices are revolutionizing the industry:

- Water-Based & Low-VOC Inks: Reduce harmful emissions.

- LED UV Curing: 50% less energy than traditional systems.

- Redukcja odpadów: CTS systems cut ink waste by 50%.

Did You Know?

- 42% of printers now use water-based inks (2022 data).

- UV inks cure 3x faster than plastisol (2-5 sec vs. 60-90 sec).

4. Screen Printing vs. DTG: Which to Choose?

| Factor | Sitodruk | Direct-to-Garment (DTG) |

|---|---|---|

| Najlepszy dla | Bulk orders, special effects | Small batches, photo prints |

| Efektywność kosztowa | Lower per unit at scale | Higher for small runs |

| Ink Options | Plastisol, puff, metallic | Water-based CMYK |

Hybrid Tip: Combine both for cost-effective, high-quality mixed runs.

5. Future Trends

- Smart Inks: Thermochromic (heat-sensitive) and photochromic (light-reactive).

- Automation: M&R Challenger III presses boost speed.

- Tusze przewodzące: For wearable tech and IoT devices.

Najważniejsze wnioski

- Match ink type to project needs (e.g., plastisol for durability, water-based for softness).

- Prioritize sustainability with LED curing and waste-reducing tech.

- Hybrid workflows optimize cost and quality.

For deeper dives, explore our guides on:

- Screen Printing Basics

- Atramenty przyjazne dla środowiska