What is Plastisol Screen Printing Ink?

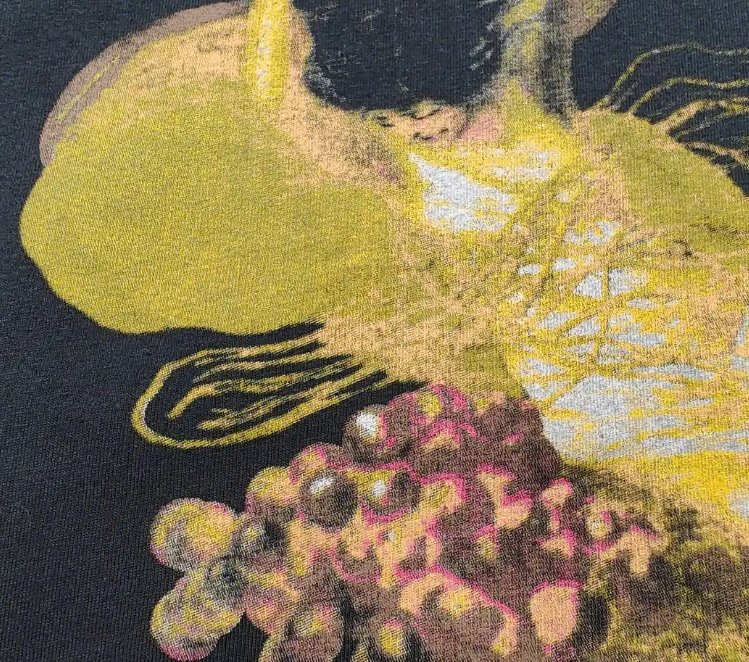

Plastisol screen printing ink is a popular choice in the screen printing industry due to its versatility, durability, and ease of use. Made from PVC particles suspended in a plasticizer, plastisol ink requires heat curing to adhere to fabrics or other surfaces. Unlike water-based inks, plastisol does not dry out during long printing sessions, making it ideal for complex and high-detail designs.

Plastisol screen printing ink is widely used for creating vibrant, long-lasting prints on garments, and brands like Wilflex Plastisol Ink have set the standard for quality and performance.

Why Use Plastisol Screen Printing Ink for High-Detail Designs?

High-detail designs demand precision and consistency, both of which are strengths of plastisol screen printing ink. Here’s why plastisol is ideal for intricate prints:

1. Opacity and Vibrancy

Plastisol ink offers excellent opacity, even on dark garments. White plastisol ink, in particular, ensures that fine details stand out, making it perfect for high-detail designs.

2. Thicker Consistency

The thicker texture of plastisol ink allows it to sit on the surface of the fabric, creating sharp, well-defined edges. This is especially important when printing designs with fine lines, small text, or intricate patterns.

3. Controlled Drying

Unlike water-based inks, plastisol does not air dry, giving printers more time to work on complex designs without worrying about ink clogging the screen.

4. Customizable Additives

Plastisol ink can be modified with additives to enhance its flow, stretch, or texture, ensuring it meets the unique demands of detailed artwork.

How Does Plastisol Screen Printing Ink Compare to Other Inks for Detail?

When evaluating plastisol ink vs. water-based ink for high-detail designs, the following considerations come into play:

Plastisol Ink

- Pros:

- Excellent for vibrant and opaque designs.

- Ideal for dark garments.

- Does not dry out on screens, allowing for more complex printing processes.

- Cons:

- Requires heat curing, which can add time and cost to the process.

Water-Based Ink

- Pros:

- Soft, breathable prints that blend into light fabrics.

- Environmentally friendly and free of harsh chemicals.

- Cons:

- Limited opacity on dark garments.

- Can dry quickly, leading to clogged screens during intricate designs.

While water-based ink has its advantages, plastisol screen printing ink remains the better choice for designs requiring sharp detail and vibrant colors.

How to Achieve High-Detail Prints with Plastisol Screen Printing Ink

Printing intricate designs with plastisol ink requires a combination of technique, tools, and preparation. Follow these tips for optimal results:

1. Choose the Right Mesh Screen

- For high-detail designs, use a fine mesh screen (200–305 mesh count) to capture intricate details.

- Ensure the screen is taut and evenly stretched to maintain precision.

2. Use a High-Quality Ink

Brands like Wilflex Plastisol Ink offer consistent performance and opacity, crucial for achieving professional-grade prints.

3. Optimize Screen Preparation

- Coat screens evenly with emulsion to avoid inconsistencies.

- Use proper exposure techniques to ensure fine details are accurately transferred.

4. Practice Consistent Curing

Curing is critical to the longevity and appearance of your print. Maintain a consistent temperature of 320°F (160°C) and use a conveyor dryer for even heat distribution.

5. Incorporate Additives

If needed, add flow enhancers or reducers to adjust the ink’s viscosity for fine details.

The Role of White Plastisol Ink in High-Detail Designs

White plastisol ink is a staple for printers working with high-detail designs, especially on dark fabrics. It serves as a base layer to enhance vibrancy and create contrast for intricate patterns.

Advantages of White Plastisol Ink:

- Opacity: Offers superior coverage on dark fabrics.

- Versatility: Can be used as a standalone color or underlay for multi-color designs.

- Durability: Maintains detail and vibrancy after multiple washes.

Whether creating logos, fine typography, or intricate patterns, white plastisol ink ensures that every detail pops.

Where to Find Plastisol Ink Near Me

Finding reliable suppliers of plastisol screen printing ink is essential for professional results. Local screen printing supply stores and online retailers often stock a wide range of plastisol inks, including Wilflex Plastisol Ink.

When searching for “plastisol ink near me,” consider these tips:

- Check for Reputable Brands: Brands like Wilflex offer consistent quality and performance.

- Look for Eco-Friendly Options: Many plastisol inks are now phthalate-free, aligning with modern environmental standards.

- Evaluate Pricing and Support: Choose suppliers that offer competitive pricing and technical support for your printing needs.

Plastisol Screen Printing Ink vs. Water-Based Ink for Professional Printers

The debate between plastisol ink vs. water-based ink often boils down to the project’s specific requirements. Here’s a quick comparison for professional printers:

Plastisol Ink

- Best for:

- High-detail designs.

- Dark garments requiring vibrant, opaque prints.

- Long-lasting, durable prints.

Water-Based Ink

- Best for:

- Soft, breathable prints on light fabrics.

- Eco-conscious or artisanal projects.

- Subtle, muted designs with natural aesthetics.

While water-based ink excels in certain areas, plastisol screen printing ink remains the preferred choice for professional printers who prioritize precision and durability.

Maintenance Tips for Plastisol Screen Printing Ink

To ensure consistent results with plastisol ink, follow these maintenance tips:

- Store Properly: Keep ink in a cool, dry place away from direct sunlight.

- Mix Before Use: Stir ink thoroughly to maintain consistency.

- Clean Screens Regularly: Prevent ink buildup by cleaning screens with appropriate solvents during long print runs.

By taking these steps, you can extend the shelf life of your plastisol ink and maintain its performance for high-detail designs.

Conclusion: Can Plastisol Screen Printing Ink Be Used for High-Detail Designs?

The answer is a resounding yes. Plastisol screen printing ink is a top choice for high-detail designs due to its opacity, durability, and precision. Whether working with white plastisol ink for bold contrasts or utilizing Wilflex Plastisol Ink for consistent quality, this versatile ink meets the demands of intricate artwork and professional printing.

If you’re looking for high-performance plastisol ink near me, explore reputable suppliers to elevate your printing projects. With the right tools and techniques, plastisol screen printing ink ensures that every detail of your design stands out.