In the vast landscape of the printing industry, selecting the right ink is akin to choosing the soulful hues that breathe life into a creation, directly influencing the final product’s visual impact and quality.

Table of Contents

I. Color Expression: Vivid Contrast vs. Subtle Elegance

The Allure of Silicone Ink’s Colors

Silicone Ink is renowned for its unique color expression, tending to showcase a warm and subtle color palette. When printed, it exhibits delicate color transitions and natural color gradients, adding a touch of understated luxury to the work. While its colors may not be as eye-catching as some high-saturation inks, Silicone Ink captivates viewers with its subtle beauty, drawing attention in an unassuming manner.

The Vibrancy of Plastisol Ink

In contrast, Plastisol Ink excels in color vibrancy. Whether it’s the bright [red plastisol ink] or the shimmering [silver shimmer plastisol ink], Plastisol Ink effortlessly achieves high-saturation color effects, making printed pieces visually rich and dynamic. Its high opacity and color saturation make it a standout in various printing scenarios, attracting attention as a focal point.

II. Touch Experience: Soft Comfort vs. Durable Toughness

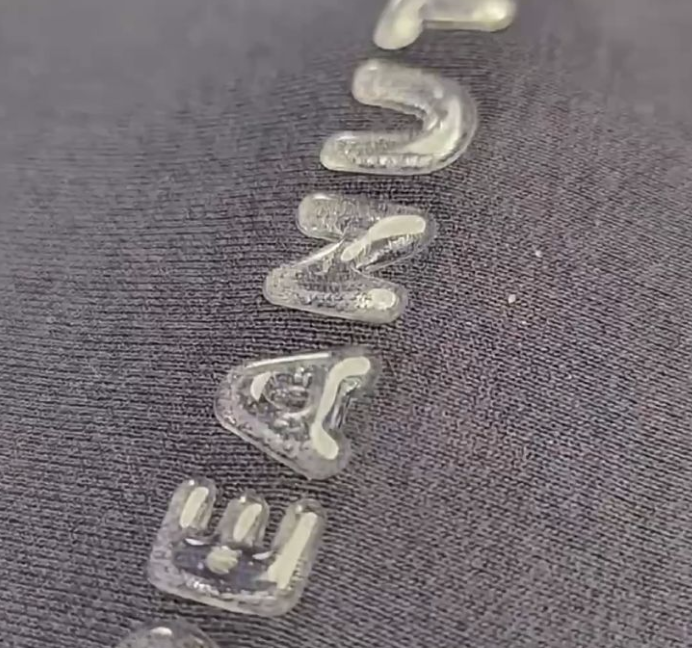

The Soft Touch of Silicone Ink

Silicone Ink shines in terms of touch experience, blending seamlessly with fabrics to provide an exceptional wearing sensation. The patterns printed with this ink are not only soft to the touch but also possess excellent elastic recovery, maintaining their shape and texture even after multiple washes and stretches. As such, Silicone Ink is particularly suitable for textile printing requiring high comfort levels, such as baby clothing and underwear. [Soft silicone ink] takes this advantage to the extreme, adding a layer of gentleness and delicacy to printed pieces.

The Durable Toughness of Plastisol Ink

While Plastisol Ink may not match Silicone Ink in terms of softness, it boasts remarkable durability. It forms a sturdy coating on various materials, protecting patterns from wear and fade. Through special formulations and techniques, [soft hand plastisol ink] and [soft plastisol ink] can also achieve impressive touch effects, balancing color vibrancy with durability.

III. Washability & Durability: Lasting Freshness vs. Challenging Conditions

The Exceptional Washability of Silicone Ink

Silicone Ink is renowned for its exceptional washability. Whether subjected to multiple washes or prolonged use, the patterns printed with Silicone Ink remain clear and fade-resistant, demonstrating remarkable durability. This feature makes Silicone Ink ideal for outdoor clothing, sportswear, and other products that endure harsh environmental conditions. Even in adverse weather, Silicone Ink-printed patterns retain their original brightness and clarity.

Plastisol Ink’s Resilience to Challenges

Plastisol Ink also exhibits outstanding durability, maintaining stable printing effects across various environments. However, under extreme conditions like high temperatures or exposure to strong chemicals, its durability may be somewhat compromised. Therefore, careful evaluation based on specific application scenarios is crucial to ensure printed pieces retain their appearance and performance over time.

IV. Special Effects & Creative Applications: Endless Possibilities & Personalized Customization

The Special Effects of silicone ink for screen printing

Silicone Ink offers endless possibilities in terms of special effects. Through specific printing processes and formula adjustments, it can achieve unique textures like matte and frosted finishes, adding a distinct charm to printed pieces. Additionally, Silicone Ink’s excellent elastic recovery makes it suitable for products requiring frequent stretching or deformation. These characteristics make Silicone Ink a versatile choice for personalized customization and creative designs.

The Creative Applications of Plastisol Ink

Plastisol Ink likewise excels in creative applications. From simple monochrome prints to complex pattern designs, [silver plastisol ink] and [silver shimmer plastisol ink] enable the realization of various visual effects, catering to individual customer needs. Whether for fashion apparel, home decor, or advertising materials, Plastisol Ink enhances works with its unique colors and textures.

Conclusion

In summary, Silicone Ink and Plastisol Ink each possess distinct advantages in printing effects. Silicone Ink stands out with its soft colors, gentle touch, and exceptional washability, making it ideal for textile printing requiring high comfort and durability. Conversely, Plastisol Ink excels in vibrant colors, durable toughness, and versatile creative applications. When selecting the right ink, it’s crucial to consider specific application scenarios, customer demands, and budgetary constraints to make an informed decision. Whether you prefer the natural elegance of Silicone Ink or the vibrant allure of Plastisol Ink, both can bring unique charm and value to your printed pieces.