Key Takeaways: Essential Curable Reducer and Plastisol Ink Insights

- Curable reducers lower the viscosity of plastisol ink, making thick inks simpler to print and enhancing waft.

- They permit for easy application, help with higher mesh counts, and deliver a smooth or vintage hand sense within the final product.

- When combined inside the proper proportions, a curable reducer keeps the authentic therapy belongings of the ink—important for durability.

- Always blend reducer thoroughly and begin with small amounts to keep away from runny ink or diminished color/opacity.

- The fn-ink™ curable reducer is a top desire for creamy, clean-to-use effects that still treatment fully.

- Proper heat and dwell time are important—despite components, never compromise on curing for lengthy-lasting prints.

- Curable reducers are essential for soft, superb, professional screen prints that your customers will note and love.

Ready to revolutionize your plastisol ink and print manner? Try including a curable reducer and release a brand new world of tender, clean, and delightful screen printing effects!

குணப்படுத்தக்கூடிய குறைப்பான் கொண்ட பிளாஸ்டிசால் மையை நான் சேமிக்கலாமா?

Ever determined your self suffering with thick, tough-to-print ink or craving for a exceptional smooth finish to your garments? The mystery weapon for printers anywhere is the curable reducer—a clever additive that transforms plastisol ink in captivating approaches. In this comprehensive submit, you’ll find out what makes curable reducers important, a way to use them efficaciously, and how they could take your display screen prints from everyday to fantastic. If you need simpler printing, softer feels, and dependable therapies, that is the should-read manual on the way to degree up your print game.

கட்டுரை சுருக்கம்

- What is a Curable Reducer and Why Do Printers Use It?

- How Does a Reducer Work With Plastisol Ink?

- What Are the Benefits of Adding a Curable Reducer to Your Ink?

- Understanding Plastisol Inks and Their Properties

- How Does Plastisol Viscosity Affect Screen Printing?

- Can a Curable Reducer Make Thick Inks Easier to Print?

- How to Mix Curable Reducer With Ink for Best Results

- What Happens to Color and Opacity When You Add a Plastisol Ink Reducer?

- fn-ink™ Curable Reducer: What Makes It Special?

- Curing and Heat: Ensuring a Durable, Soft Print

1. What is a Curable Reducer and Why Do Printers Use It?

A curable reducer is a specialty additive designed for use with plastisol ink within the display screen printing manner. Its fundamental function? To decrease the viscosity of plastisol ink, making thick inks smoother, thinner, and dramatically simpler to print. If you’ve ever confronted inks so thick they make your squeegee groan, or you’re after that dreamy, tender hand feel to your finished product, then you definitely want to add a curable reducer to your toolkit.

One reason printers rave approximately curable reducers is their capacity to hold the center property of the ink—it will nonetheless treatment just like preferred plastisol ink. This “remedy” capability is what sets a curable reducer aside from frequent thinners that threat compromising the curing system or negative the cease product. That’s why deciding on the right reducer is essential for regular, exceptional prints.

2.How Does a Reducer Work With Plastisol Ink?

Working with plastisol ink may be intimidating, in particular whilst it’s ultra-thick or tricky to address. That’s where a reducer steps in. When you introduce a பிளாஸ்டிசோல் மை குறைப்பான், you right away decrease its viscosity. The ink turns into more workable and flows greater easily through the mesh at some stage in the display print process.

This viscosity adjustment is important for packages where you need to push ink thru higher mesh counts or reap a soft, skinny deposit on the garment. Depending at the ink colour and base, a few inks (like white or strong point metallics) are clearly thicker. With a nicely-mixed reducer, the ink spreads like butter with out turning runny or dropping color brilliance—a really transformative effect for any printer aiming for ease and efficiency all through production.

3. What Are the Benefits of Adding a Curable Reducer to Your Ink?

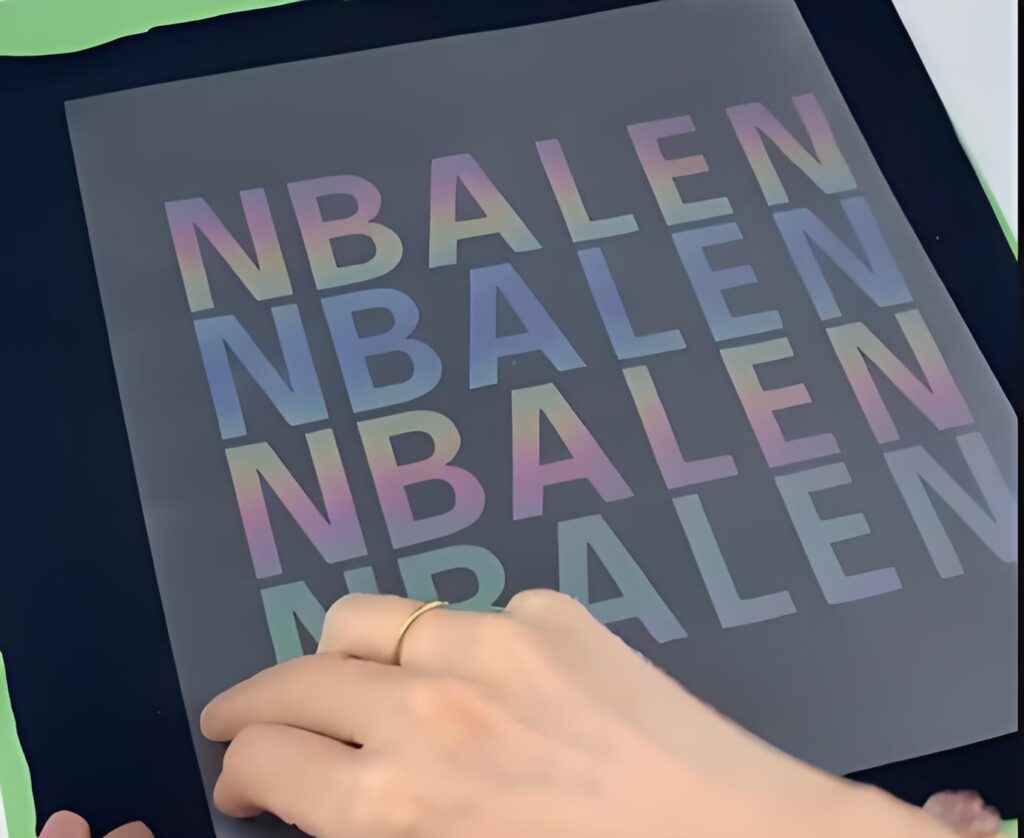

The perks of using a curable reducer move beyond mere convenience. First, by way of decreasing the viscosity, it makes thick plastisol inks an awful lot less complicated to print. This means smoother, quicker prints and less effort required from the squeegee operator. Secondly, it permits you to apply better mesh counts, permitting finer detail and decreasing ink weight at the garment for a softer experience.

Curable reducers also help deliver a creamy texture that’s easier to mix, making colour changes and blending a breeze. Instead of combating with “cussed” ink, you’ll be rewarded with creamy, potential plastisol on every occasion. Most importantly, considering that this form of reducer is formulated to remedy below standard plastisol conditions, your completed product retains durability and wash resistance. Essentially, adding a curable reducer helps you attain excellent smooth hand, antique print aesthetics, and standard superior utility

4. Understanding Plastisol Inks and Their Properties

Plastisol ink is a completely unique product—neither water-based totally nor air-drying, it stays wet till uncovered to right heat. This ink is the powerhouse of screen printing, prized for its opacity, vibrant colour, and durability. However, its viscosity (or thickness) can occasionally be a challenge, specifically whilst you want easy, smooth consequences or when the usage of better mesh counts on the display.

The center property of plastisol is that it requires warmness to therapy. That method you need to attain a specific temperature in the course of the curing technique—normally round 320°F (a hundred and sixty°C) for correct bond and wash durability. Some colorings, like white ink or metal sunglasses, have thicker viscosity with the aid of design. A பிளாஸ்டிசோல் மை குறைப்பான் is often the most effective manner to make these tough inks greater workable and easier to print without compromising their capability to therapy and resist put on.

5. How Does Plastisol Viscosity Affect Screen Printing?

The viscosity of plastisol ink determines how it flows, spreads, and deposits onto your garment. High-viscosity (thicker) inks may be hard—they won’t skip cleanly through higher mesh counts, and they will go away a heavy, plastic-like hand at the garment. Meanwhile, decrease viscosity inks are smoother to print, permitting you to apply nice mesh, create gentle hand prints, and reap extra delicate information.

Inks like white, regularly built for opacity, may be particularly thick. This may additionally assist with insurance, however it regularly makes the printing procedure hard work-intensive and less regular. A curable reducer brings stability by means of reducing the thickness of the ink (without making it runny), so that you can enjoy an application that’s each easy on your gadget and captivating on your customers—suppose antique prints or light, tender hand effects.

6.Can a Curable Reducer Make Thick Inks Easier to Print?

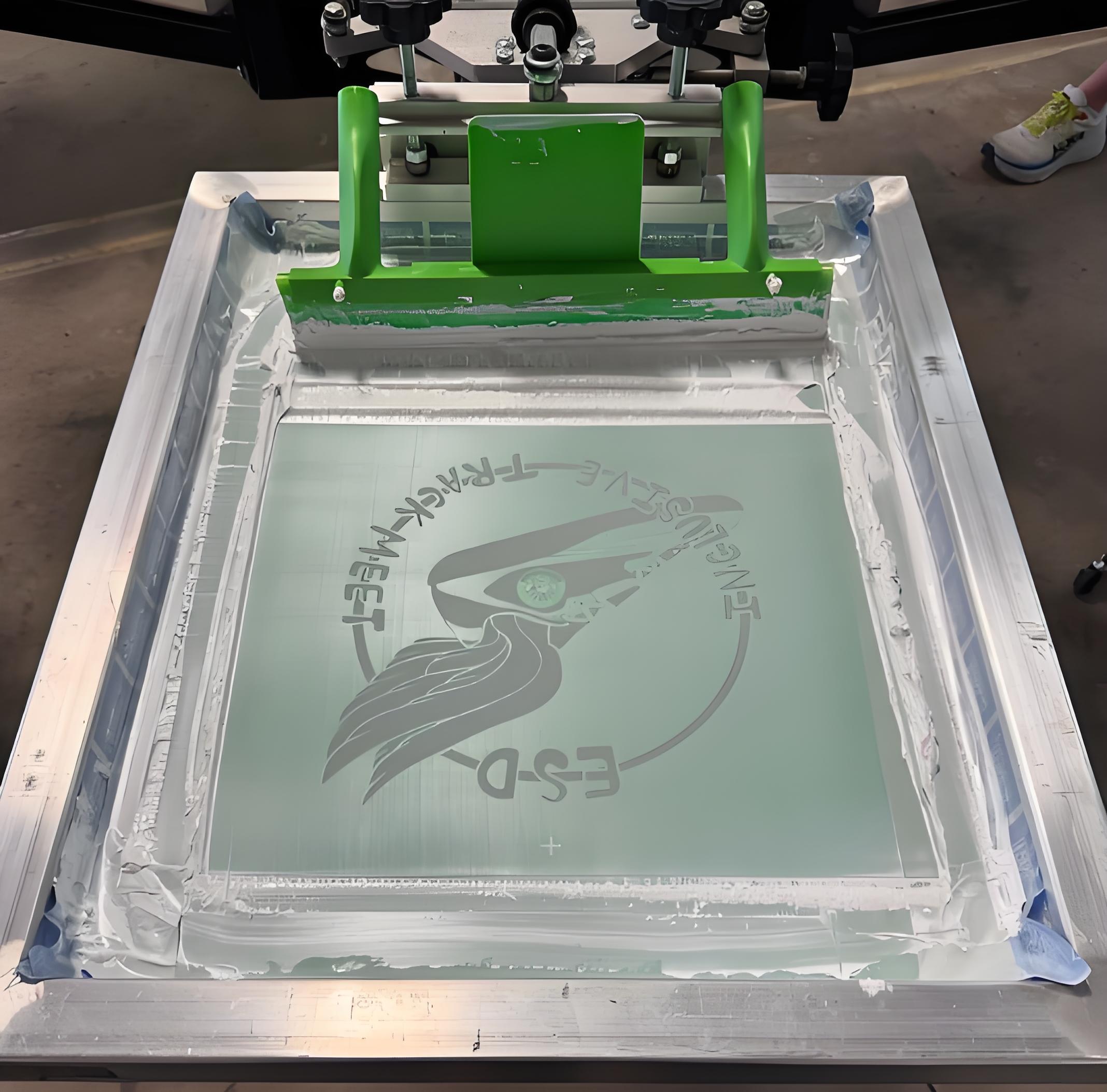

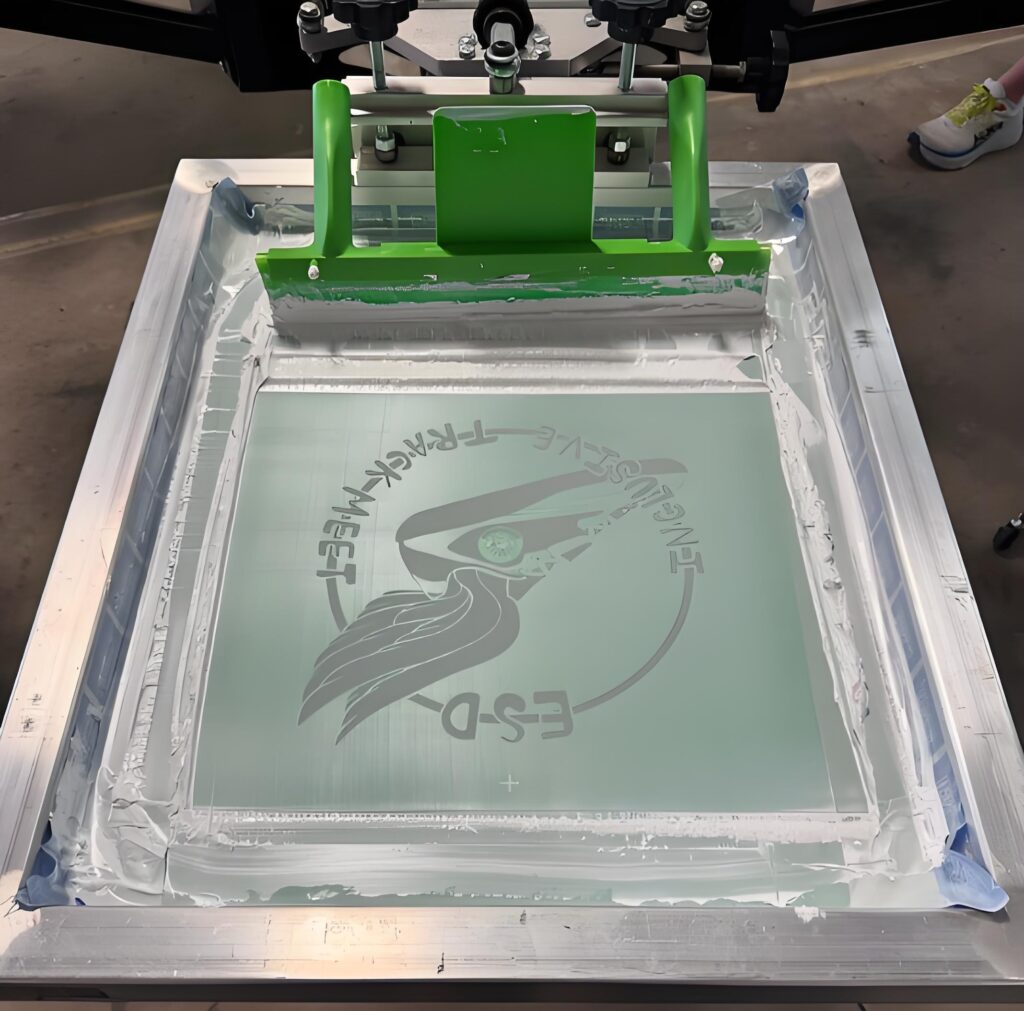

Absolutely! If you’ve ever wrangled with thick inks, you recognize the battle—a heavier squeegee pull, uneven software, and from time to time rough prints. That’s exactly why many printers turn to a curable reducer. By decreasing the viscosity, the ink profits a creamy texture that glides throughout the screen and deposits more easily on the garment.

Not best do curable reducers make ink easier to print, they also assist while working with better mesh counts or specific designs. The result? Cleaner prints, superb smooth hand, and less pressure on the printer and squeegee. You don’t want brute force; utility will become more manageable, and you’re much less in all likelihood to revel in ink buildup or clogging troubles—transforming even the thickest inks right into a possible product

7. How to Mix Curable Reducer With Ink for Best Results

Mixing is an important step while working with any ink additive. To add a curable reducer for your ink nicely, start with a small percentage (usually 2-5% by using weight, but this can range relying on the ink and desired softness). Mix thoroughly with a spatula or mixing blade until the plastisol ink takes on a thinner, creamy consistency.

Take care now not to overdo it—an excessive amount of reducer can affect the assets of the ink, making it too thin or potentially destabilizing the colour. Test your aggregate with a important points earlier than scaling up. Monitoring the opacity of the ink and the way it prints onto the garment ensures you don’t lose insurance or color vibrancy. Always test the manufacturer’s suggestions, like those found at screenprinting.Com or worldwide coatings, specially for forte inks or colorings.

8. What Happens to Color and Opacity When You Add a பிளாஸ்டிசால் மை குறைப்பான்?

Any time you alter an ink, it’s essential to take into account how it’ll have an effect on its important residences. Adding a curable reducer to ink will decrease the viscosity, making it easier to print, but overuse can once in a while lessen opacity or barely lighten colour, particularly with enormously pigmented plastisol formulations.

In maximum instances, using the advocated quantity preserves the vibrancy of your ink color and maintains the opacity wanted for bold, top notch prints—even if the use of better mesh counts. However, printing on dark clothes or the usage of uniqueness colorings may additionally require a test run. Always determine the very last product to make certain it meets your requirements for insurance, colour brilliance, and typical application nice.

9. Fn-ink™ Curable Reducer: What Makes It Special?

Among the many merchandise to be had, fn-ink™ curable reducer stands out for its versatility and simplicity of use. Designed mainly for plastisol inks, this reducer is praised for its capability to lower the viscosity without sacrificing treatment or durability. The result? Creamier, softer-feel prints that keep the original houses of the plastisol base.

Printers like fn-ink™ curable reducer as it works throughout numerous inks—whether or not you’re tackling white, distinctiveness, or trendy plastisol. It’s formulated to permit tender hand, antique-style prints, and is equally powerful on precise designs that require better mesh counts. If you’re searching out easier utility, a product that doesn’t compromise cure, and a smoother print revel in, keep in mind making fn-ink™ your cross-to additive.

10.Curing and Heat: Ensuring a Durable, Soft Print

No matter what additives or reducers you select, the curing procedure remains non-negotiable for plastisol ink. Proper therapy guarantees your product is durable, washable, and proof against wear or cracking. Most plastisol inks, even if a curable reducer is brought, require a final therapy temperature round 320°F (one hundred sixty°C) to completely set.

Pay attention on your warmth source—whether conveyor dryer or flash devices—and reveal temperature and stay time closely. Adding reducer typically doesn’t alternate the fundamental cure temperature, but the usage of an excessive amount of would possibly make the ink lay thinner, doubtlessly requiring a mild adjustment in stay time. The end result, when finished proper, is a tender print that stands the take a look at of time, maintaining each feel and coloration richness