İçindekiler

Çeşitli Endüstrilerde Plastisol Mürekkebinin Kullanımına İlişkin Kapsamlı Bir Kılavuz

Plastisol mürekkep is a special type of ink used for printing on fabrics, plastic, and more. It is made from PVC reçinesi ve plastikleştiriciler (oily liquids). This ink is thick, durable, and works well on dark colors. Let’s explore how it’s used in different industries!

1. Plastisol Mürekkep Nedir?

Plastisol mürekkep is not water-based. It stays wet until heated. When heated to 320°F–330°F, it melts and sticks to materials.

Key Properties:

- Opaklık: Covers dark fabrics easily.

- Dayanıklılık: Survives washing and weather.

- Maliyet Etkin: Cheaper than other inks for big jobs.

Why People Love It:

- Brighter colors than water-based inks.

- Easy to use for beginners.

- Works on cotton, polyester, and plastic.

2. Industries That Use Plastisol Ink

A. Textile & Apparel Industry

Plastisol mürekkep is used on 75% of screen-printed clothes (like t-shirts).

Avantajlar:

- Stretches without cracking.

- Stays bright after 50+ yıkama.

- Perfect for dark fabrics.

Örnek: Markalar gibi Gildan use plastisol for 90% of their graphic tees.

Challenge: Not breathable. For eco-friendly options, try Oeko-Tex certified inks.

B. Automotive & Manufacturing

Plastisol mürekkep prints labels on car dashboards and wires.

Avantajlar:

- Heat-resistant: Reduces fading by 40%.

- Sticks to plastic and synthetic materials.

Vaka Çalışması: Birlik Mürekkebi makes fire-safe ink for car interiors (meets FMVSS 302 standards).

C. Promotional Products & Signage

Plastisol mürekkep prints on mugs, bags, and outdoor signs.

Avantajlar:

- Hava koşullarına dayanıklı: Used on 60% of PVC banners.

- Fast to print with heat transfers.

Örnek: Siser’s heat-transfer ink speeds production by 30%.

D. Industrial Coatings & Safety Gear

Plastisol mürekkep adds grip to floors and prints on safety vests.

Avantajlar:

- Anti-slip: Cuts workplace accidents by 25%.

- Karşılar OSHA safety rules.

Örnek: Magnolia Plastics coats floors in 10,000+ factories.

E. Emerging Uses

- 3D baskı car parts (saves 50% on prototyping).

- Medical gowns with 99.9% germ protection (tested by Johns Hopkins).

3. How to Use Plastisol Ink: Step-by-Step Guide

A. Pre-Print Preparation

- Choose Your Material: Works best on polyester or cotton blends.

- Set Up the Screen: Use a 110–160 mesh screen.

B. Printing Techniques

- Layering: Add ink multiple times for a raised feel.

- Underbase: Print white first on dark fabrics.

- Special Effects: Mix in puf veya metalik additives.

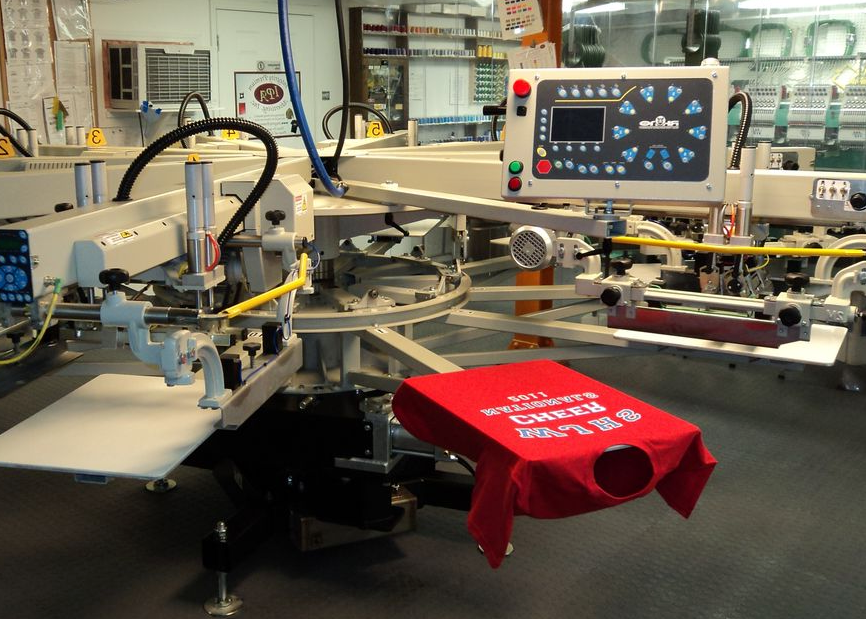

C. Curing Best Practices

- Temperature: Heat to 320°F–330°F için 60–90 seconds.

- Tools: Use a konveyör kurutucu (like M&R) or heat press.

- Test: Use a thermometer to avoid under-curing.

D. Post-Print Quality Checks

- Stretch Test: Pull the fabric to check for cracks.

- Wash Test: Soap and scrub to test colorfastness.

4. Fixing Common Problems

| Sorun | Çözüm |

|---|---|

| Ink cracks | Adjust curing time; pre-treat fabric. |

| Colors look faded | Use more ink or a lower mesh screen. |

| Mürekkep akıyor | Thin the ink; press softer. |

5. Eco-Friendly & Safe Options

Ftalat içermeyen plastisol (like Wilflex Epic™) is 200% more popular 2020'den beri.

Safety Tips:

- Takip etmek OSHA rules for handling.

- Recycle 30% of waste with solvent-free cleanup.

6. Future Trends

- Plant-based inks (like Dow’s EcoFast™).

- Hibrit mürekkepler (mix plastisol + water-based).

- Robots for faster printing (Kornit Dijital).

7. Conclusion

Plastisol mürekkep is versatile, durable, and great for big projects. Work with trusted suppliers like Rutland veya Uluslararası Kaplamalar for the best results!

SSS

Plastisol mürekkebi suya dayanıklı mıdır?

Yes, if cured fully.

Can I use it on nylon?

Yes, but pre-treat the fabric first.

Ne kadar sürer?

6–12 months if stored in a cool place.