İçindekiler

Serigrafi Baskı Mürekkeplerini Anlamak: Türleri, İpuçları ve Teknikleri

Screen printing inks are eğlence ve önemli. They make our art bright and strong. In this article, we will learn about screen printing inks. We will talk about types, ipuçları, Ve techniques. We will use a table and lists. We will also use simple words so it is easy to read for everyone[^1].

What Are Screen Printing Inks?

Screen printing inks are Choose special colors in block printing ink for unique designs.. They go on a screen, then on a shirt or sign. The ink shows our art so it looks nice ve Serin. The type of ink you choose can change the look and life of your work. It also changes how easy it is to print. Using the right ink will give you parlak colors and make your print last long.

Serigrafi Baskı Mürekkeplerinin Çeşitleri

There are many kinds of ink. Each one has its artıları ve eksileri. Here are the main types:

1. Plastisol Inks

- Artıları:

- Güçlü ve canlı renkler.

- Easy for first timers.

- Dayanıklı on many fabrics.

- Eksileri:

- They need heat to dry.

- They have PVC.

En iyisi:

- T-shirts and high-opacity designs.

- Many shops use these inks because they are popular[^2].

2. Water-Based Inks

- Artıları:

- More çevre dostu.

- Onlar bir tane veriyorlar soft look.

- They spread into the fabric.

- Eksileri:

- They dry fast.

- They require more skill.

En iyisi:

- Sustainable printing and light fabrics.

- People who care for the earth love these inks[^3].

3. Discharge Inks

- These inks remove the color in dark fabrics.

- Onlar bir tane veriyorlar vintage look.

- En iyisi:

- Designs on cotton with an old-school vibe.

4. Specialty Inks

There are many cool special inks:

- UV-Curable Inks:

- Dry fast when exposed to UV light.

- They use less energy.

- Puff Inks:

- Elde etmek puffy when they are heated.

- They give a 3D touch.

- Metallic / Glow-in-the-Dark Inks:

- They add a special quality to garment printing. ışıltı veya glow to prints.

These inks can make your work öne çıkmak with unique looks.

How to Choose the Right Ink

It is important to choose the right ink. Here are some ways to pick the best ink:

- Kumaş Türü:

- Cotton, polyester, or blends need different inks.

- Sona ermek:

- Bir şey ister misin? glossy look, a matte look, or a textured finish?

- Climate Impact:

- Look for PVC-free or solvent-free inks if you love our earth.

- Equipment:

- Do you have a heat press, dryer, or UV lamp?

Screen Printing Ink Application Tips

To get great prints, follow these tips:

1. Pre-Press Preparation

- Clean your screen.

- Remove dust and old ink.

- Coat with emulsion.

- This helps you make a clear design.

- Test print.

- Do a small test before your big print.

2. Ink Mixing & Consistency

- Mix your ink well.

- Good mixing gives smooth ink.

- Control the viscosity**

- Use reducers or retarders if needed.

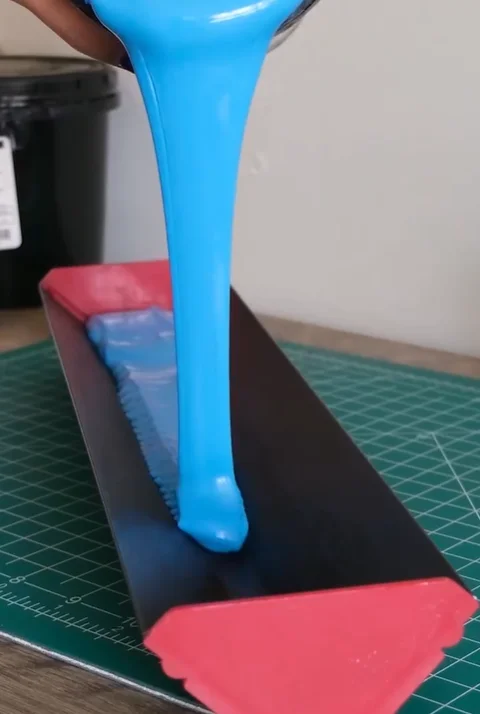

3. Squeegee Techniques

- Hold the squeegee at a good angle.

- Kullanmak the right pressure for smooth ink.

- Pratik silecek basıncı to get a neat print.

4. Curing Methods

- Isı Presi:

- Great for plastisol.

- Konveyör Kurutucu:

- Cures many prints fast.

- Flash Curing:

- Use short bursts of heat (flash curing) when printing extra colors.

These steps help the ink stick well and last a long time.

Advanced Techniques for Better Prints

To make your prints look even better, try these tricks:

1. Multi-Color Printing

- Kullanmak tescil işaretleri so each color fits.

- Do an alt taban layer.

- Kullanmak flash curing between layers.

2. Simulated Process Printing

- Kullanmak yarı tonlar for smooth color blending.

- This works for photorealistic designs.

3. Gradient and Blending Effects

- Denemek wet-on-wet printing.

- Kullanmak split-fountain Teknikler.

- These make soft color changes.

4. Mesh Count and Emulsion Coating

- Use a fine örgü sayısı (230–305) for sharp details.

- Emulsion coating quality is key to clean prints.

Common Screen Printing Ink Problems and Fixes

Even grown-ups can have print problems. Here are some common issues and easy fixes:

1. Ink Bleeding

- Sorun: Ink goes beyond its edge.

- Cause: Too much pressure or low örgü sayısı.

- Düzeltmek:

- Daha yüksek gözenek sayısı kullanın.

- Adjust the silecek basıncı.

2. Poor Adhesion

- Sorun: Ink does not stick well, especially with low opacity inks.

- Cause: Not curing the ink properly.

- Düzeltmek:

- Check your heat source and time.

- Make sure to tedavi the ink well.

3. Screen Clogging

- Sorun: Ink builds up in the screen.

- Cause: Dried ink blocks the screen.

- Düzeltmek:

- Clean the screen right away.

- Use screen opener.

4. Pinholes or Inconsistencies

- Sorun: Small holes or spots in prints.

- Cause: Dust or problems in your emulsion coating.

- Düzeltmek:

- Clean your screen thoroughly before use.

- Re-coat the screen with fresh emulsion.

Eco-Friendly Screen Printing Practices

Many printers now care for our planet. Here are çevre dostu tips:

Water-Based vs. Plastisol Inks

- Su bazlı mürekkepler vardır yeşil.

- They are used by 40% of printers today.

- Plastisol mürekkepler are strong but not as green.

Recycling and Cleaning

- Recycle used inks.

- Use eco-friendly cleaning solutions.

- Look for inks that are PVC içermez.

Certifications

- Aramak EU REACH and similar labels.

- Certified inks help keep you safe and green.

Data and Statistics on Screen Printing Inks

The table below shows some useful data. It helps us see the industry trends and key facts.

| Kategori | The table below shows some useful data on fabric screen printing inks. | Kaynak | İlgililik |

|---|---|---|---|

| Market Trends | Market grows at 4.8% CAGR (2023–2030) | Grand View Araştırması (2023) | Shows more people print arts. |

| Mürekkep Kullanımı | 65% of the market uses plastisol inks | Smithers Pira Report (2022) | Plastisol is very common. |

| Sürdürülebilirlik | 40% of printers use water-based or eco-solvent inks | FESPA Global Print Expo (2023) | More people choose green inks. |

| Kürleme Verimliliği | UV inks lower energy use by 30% | RadTech UV Study (2021) | UV inks help the earth. |

| Vaka Çalışması | “EcoThreads” cut waste by 50% with discharge inks on organic cotton | Sustainable Brands (2023) | Shows how discharge inks are good for green work. |

| Ortak Sorunlar | 25% of defects come from wrong mesh count | ScreenPrinting.com (2023) | Good mesh count is very important. |

| Maliyet Analizi | Water-based inks cost 20% more but save on waste fees | Wilflex Ink Cost (2023) | Compare cost with long-term savings. |

| Durability Stats | Properly cured plastisol lasts 50+ washes; bad curing makes prints 70% worse | Int. Coatings Lab (2022) | Curing is key to long-lasting prints. |

| Vaka Çalışması | “PrintPros” raised output by 35% using smart ink mixing systems | Printwear Magazine (2023) | Tech can help your prints. |

| Consumer Preference | 60% of buyers like soft-hand prints made by water-based inks | SGIA Consumer Survey (2023) | Use water-based inks for a soft feel. |

| Equipment Impact | Using a 230–305 mesh count helps in neat simulated process printing | Ryonet Technical Guide (2023) | Mesh count matters in fine art. |

| Regulatory Data | PVC-free inks meet EU REACH standards | EU Chemical Regulation Database | Follow rules and stay safe. |

| Vaka Çalışması | Kiwo’s hybrid inks cut screen clogging by 90% in high-volume jobs | Kiwo Success Story (2023) | Hybrid inks work well for big orders. |

| Yıkanabilirlik | Discharge inks keep 95% color after 30 washes on cotton | Jacquard Testing (2022) | Good for lasting color. |

| Eğitim Etkisi | Trained printers get 50% fewer errors related to ink use | PRINTING United Alliance (2023) | Training is very helpful. |

| Niche Apps | Conductive inks are used in 15% of wearable tech kits | IDTechEx Report (2023) | Use specialty inks for tech prints. |

| Eco-Certifications | SGP-certified printers save $5k yearly with less waste and energy | SGP Case Study (2023) | Certs save money and resources. |

Practical Steps to Get the Best Results

Here are clear and simple steps to follow for a Harika print:

- Prep Your Work

- Clean your screens.

- Use fresh emulsion for a clear design.

- Mix Your Ink

- Stir well until the ink is smooth.

- Do not let the ink dry.

- Print with a Good Squeegee

- Hold the squeegee at an angle.

- Press with the right silecek basıncı.

- Use even strokes for a neat finish.

- Cure Your Ink

- Use a heat press or a dryer.

- Check each print for cures to ensure the opacity of your colors.

- Review and Fix Issues

- Look for ink bleeding or pinholes.

- Fix your mesh count or clean your screens.

These steps help you make prints that are uzun ömürlü ve parlak.

Tips for Using Specialty Inks

Special inks can make your art unique. Here are some simple tips:

- UV-Curable Inks:

- Use a UV light to cure the ink fast.

- They save energy by using 30% less power[^2].

- Puff Inks:

- They puff up when you heat them.

- They make a fun, 3D look.

- Metallic and Glow-in-the-Dark Inks:

- Use these inks for a special effect.

- They add sparkle or shine to your design.

When you use these inks, follow the same steps: mix, print, and cure.

A Look at Advanced Techniques in Detail

Advanced techniques can take your print from iyi ile inanılmaz. Let us look more closely.

Multi-Color Printing

- Plan Ahead:

- Make a plan with each color.

- Use Registration Marks:

- These marks help colors line up.

- Underbase Layer:

- Print a light color first, then add other colors.

- Flash Curing:

- Cure between layers to stop the ink from moving[^2].

Simulated Process Printing

- Halftone Blending:

- Use tiny dots to blend colors.

- Step-by-Step:

- Print layers slowly.

- Watch the colors mix.

Gradient and Blending Effects

- Wet-on-Wet Technique:

- Print colors on wet ink to make a smooth blend.

- Split-Fountain Technique:

- Use one squeegee with two colors.

These techniques can make your prints look like real art.

Learning and Training

It helps to learn from experts. Training can lower your mistakes by 50%[^2]. Here are ways to get better:

- Online Tutorials:

- Find videos and simple guides.

- Workshops:

- Join a class near you.

- Pratik:

- The more you print, the better you get.

Try to learn about örgü sayısı ve emülsiyon kaplama. Try different squeegee techniques. Each practice makes you a better printer, especially when using Speedball fabric inks.

FAQs about Screen Printing Inks

Below are some common questions and answers:

Can I mix plastisol and water-based inks together?

No, mixing them can cause problems with your print.

How many washes do prints last?

Well-cured plastisol can last 50+ washes. But if not cured, the print can fall part.

What is the best ink for stretchy fabrics?

Water-based inks work best for soft, stretchy fabrics.

Will UV-curable inks save energy?

Yes, they use 30% less energy.

Which ink is best for a green project?

Water-based, discharge, or specialty eco inks are good choices.

A Recap: Key Points to Remember

- Serigrafi Mürekkepleri make our art bright.

- There are many types: Plastisol, water-based, discharge, and specialty.

- Bu doğru mürekkep depends on your fabric, finish, and eco needs.

- İyi kullan squeegee techniques ve örgü sayısı for perfect prints.

- Practice and training help you use inks well.

- Kullanmak çevre dostu inks for a brighter, green future.

A Working Table for Quick Reference

Here is a quick lookup table to help you remember important facts:

| Type / Factor | Anahtar Nokta | Uç |

|---|---|---|

| Plastisol Mürekkep | Common ve canlı. Needs heat cure. | Use for T-shirts and bold art. |

| Su Bazlı Mürekkep | Çevre dostu and soft. Dries fast. | Best for light fabrics, green work. |

| Deşarj mürekkebi | Removes dye for a vintage look. | Great for cotton with old-school flair. |

| Specialty Ink | UV curable, puff, metallic, glow. Use as needed. | Adds special effects to prints. |

| Örgü Sayısı | 230–305 for details. | Use a fine mesh for thin prints. |

| Silecek Basıncı | A balanced push gives even ink. | Practice for a neat finish. |

| Flaş Kürleme | Quick heat bursts for extra layers. | Use for multi-color prints. |

| Emülsiyon Kaplama | Keeps details sharp. | Clean screen helps the emulsion stick. |

Sonuç

Screen printing inks are the heart of great prints. With many kinds of ink, you can choose what is best for you. By following these simple tips, you can make art that is parlak, uzun ömürlü, Ve Güzel. Remember to use good örgü sayısı, the right silecek basıncı, and do flash curing at the right times. Practice, learn, and try new tools like Wilflex, Hız topu, Ve Jacquard inks. These steps help in making every print your best work.

Each step, from pre-press to curing, adds a special touch to your work. Use eco-friendly inks to care for our earth. Let your prints shine with color and life. If you follow our tips and check the facts like the market trend ve common issues, your prints will get better every day.

Stay curious and keep learning. There are many ways to make your screen printing art even more fun. Use training, try advanced techniques, and read about özel mürekkepler to expand your skills. With time and care, you will make prints that are loved by many.

Thank you for reading. We hope you now know more about serigrafi mürekkepleri. Make your art canlı ve lasting. Happy printing!