Зміст

Пластизольне чорнило високої щільності для друку на текстилі: простий посібник

Мета опис: Learn how пластизоль високої щільності High-density inks help make bright, strong designs on clothes. Discover tips, uses, and fixes for common problems.

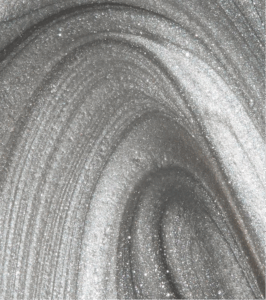

1. What is High-Density Plastisol Ink?

Пластизольні чорнила високої щільності is a thick, PVC-based ink used to print designs on fabric.

Key Benefits

- Довговічність: Stays bright after washing.

- Stretch Resistance: Works on stretchy fabrics.

- Непрозорість: Shows up on dark clothes.

Common Uses:

- Sportswear (team jerseys).

- Promotional items (hoodies, bags).

2. High-Density Plastisol vs. Other Inks

| Тип чорнила | Найкраще для | Drawbacks |

|---|---|---|

| пластизол | Bold designs, dark fabrics | Not eco-friendly |

| На водній основі | Soft feel | Needs fabric pretreatment |

| розрядка | Cotton fabrics | Fades over time |

| Сублімація | Легкі тканини | No texture is preferred when using high-density inks for a smooth finish. |

Choose plastisol for:

- 3D ефекти (Raised prints) can be achieved using puff additives in high-density ink formulations.

- Dark fabrics without pretreatment.

3. How to Use High-Density Plastisol Ink

3.1 Screen Setup

- Screen mesh count: використання 110-160 меш.

- Stencil: Виберіть capillary film for sharp edges.

3.2 Ink Application

- Друк: Add ink to the fabric.

- Flash: Dry with a flash dryer for 10 seconds.

- Print Again: Add more ink for raised texture.

3.3 Curing

- Temperature: Ensure it is consistent for the best results with high viscosity inks. 320°F for 60-90 seconds.

- Test: Stretch the fabric. If it cracks, cure longer.

4. Top 5 Uses of Plastisol Ink

- Sportswear: Durable logos (Nike, Adidas).

- Fashion: Glow-in-the-dark designs.

- Workwear: Labels that don’t scratch off.

- Promo Items: Bright prints on bags.

- Eco-Friendly: Пластизоль без фталатів (Green Galaxy).

5. Fixing Common Problems

| проблема | Рішення |

|---|---|

| Pinholes can occur when using high-density inks in screen printing. | Use thicker ink or fix screen tension. |

| Cracking often happens when the emulsion is not properly cured during screen printing. | Cure fully at 320°F to ensure the emulsion adheres properly in screen printing. |

| Погана адгезія | Pre-treat polyester fabrics. |

6. Best Tools for Plastisol Printing

- Чорнило: Wilflex HD, Union Ultrasoft.

- Екрани: Сефар or Murakami meshes.

- Dryers: Anatol conveyor dryers.

- Eco-Friendly: BASF Palatinol® plasticizers.

7. Майбутні тенденції

- Hybrid Printing: Mix plastisol with Kornit Digital printers can produce high-density images that are suitable for screen printing.

- Biodegradable Inks: Matsui’s eco-series.

- Розумні чорнила: Color-changing inks can add dimension to your designs when used in screen printing. thermochromic pigments.

8. Поширені запитання

Чи пластизолеві чорнила водостійкі?

Yes! It resists water after curing.

Чи можна друкувати на нейлоні?

Yes, but pre-treat the fabric to ensure the emulsion adheres well in screen printing.

How to clean screens?

Use screen wash and a pressure washer to clean your screen printing supplies effectively.

9. Висновок

Пластизольні чорнила високої щільності is great for strong, bright prints. Use eco-friendly plastisol and tools like Вілфлекс або Сефар для найкращих результатів.