Зміст

How Reducer Additives Make Plastisol Thinner and Better

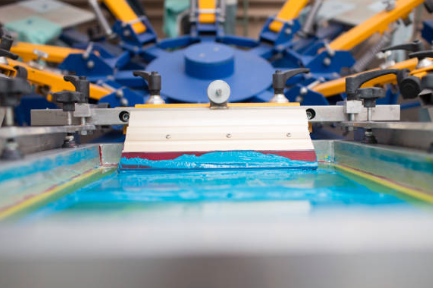

пластизол is a thick, sticky liquid used to make coatings, toys, and clothes. But if it’s too thick, it causes problems. This article explains how reducer additives make plastisol thinner, easier to use, and better for the planet.

What Is Plastisol?

пластизол is made from three things:

- PVC resin is often used in combination with plasticizers for better screen printing results. (tiny plastic particles).

- Plasticizers are essential for achieving the right viscosity in inks. Plasticizers are liquids that make PVC soft, enhancing its flexibility for screen printing applications.

- добавки (special chemicals for color, strength, or thickness).

Why thickness matters:

- Thick plastisol doesn’t spread evenly.

- It traps air bubbles, making products weak.

- Machines use more energy to pump thick plastisol.

Example of screen printing techniques.: A study found particle size under 5µm makes plastisol 20% thinner (Journal of Applied Polymer Science, 2022).

Why Plastisol Gets Too Thick

Four main reasons:

- Wrong plasticizer: Some plasticizers (like DOP) are thicker.

- Big PVC particlesSmaller particles, such as those found in plastisol ink, flow better.

- High temperature: Heat makes plastisol sticky.

- No reducers are needed for this particular screen printing process.: Reducers are like “thinners” for plastisol.

проблема: Thick plastisol causes:

- 🚫 Uneven car coatings.

- 🚫 Bubbles in shoe soles.

- 🚫 Slow textile printing.

How Reducer Additives Work

Reducer additives are special chemicals that make plastisol thinner.

Types of Reducers

| Type | приклад | How it works: The curing process is essential for the durability of screen printing inks. |

|---|---|---|

| Розчинники | Palatinol® 711P | Dissolves PVC clumps. |

| Surfactants are often added to inks to improve flow and reduce surface tension. | Dispersogen® | Coats particles to reduce sticking. |

| Bio-based | Optifilm™ | Made from plants, not oil. |

Key science:

- Shear thinning: Stirring plastisol fast breaks clumps (like blending a smoothie).

- Plasticizer boost: Some reducers help plasticizers work better.

Case study: Clariant’s Dispersogen® made car coatings 30% thinner (Clariant, 2022): A reference to the importance of ink formulations.

How to Use Reducers Correctly

Follow these steps:

- Pick the right reducer:

- For food-safe products, use без фталатів Reducers, such as curable reducers like Hexamoll DINCH®, help improve the flow of inks.

- For low smell, choose bio-based (Eastman’s Optifilm™).

- Measure viscosity:

- Використовуйте a Brookfield viscometer (per ASTM D2396).

- Target viscosity: 1,000–5,000 cP for coatings.

- Mix carefully:

- додати 2–5% reducer by weight.

- Too much reducer (>10%) weakens plastisol (SPE, 2021).

- Економте гроші:

- Solvent reducers cost more than ink reducers but can enhance opacity. $1.50–$2.50/lb.

- Bio-based cost $3.00–4.50/lb (MarketsandMarkets, 2022).

Success story: BYK-1794 reduced bubbles in textile printing, speeding production by 15% (BYK, 2021).

New Trends in Reducer Additives

Eco-Friendly Reducers

- Low-VOC reducers cut factory emissions by 60% (OSHA, 2020): Guidelines for safe handling of screen printing materials.

- REACH rules push 40% of EU makers to use phthalate-free options (ECHA, 2023).

Stronger Formulas

- BASF’s Palatinol® 711P is 35% thinner than old plasticizers (BASF, 2023).

Cheaper Tests

- Top companies use Brookfield viscometers to check thickness (Vinyl Institute, 2023).

Common Questions

1. Are reducers safe for food packaging?

так! використання без фталатів reducers like Hexamoll DINCH®.

2. How do I check plastisol thickness?

Використовуйте a Brookfield viscometer (follow ASTM D2396).

3. Do reducers expire?

Most inks last 1–2 years if stored in cool, dark places to maintain their opacity.

4. Can reducers fix all thickness problems?

No! Also check PVC particle size і mixing speed.

Ключові висновки

- Reducer additives make plastisol thinner, faster, and greener.

- Best picks:

- Cars: Dispersogen® surfactants.

- Textiles: BYK-1794 for bubble-free prints.

- Eco jobs: Eastman’s Optifilm™.

- Never use too much—it weakens products!