When it involves screen print, the ink you select determines not simply the exceptional however additionally the fulfillment of your whole challenge. From the flexibility of plastisol ink to fashionable water-based totally options, knowledge screen printing ink is crucial for colourful colors, durability, and achieving professional outcomes. Whether you’re an aspiring artist, seasoned printer, or going for walks a print supply shop, this newsletter will cover the whole thing you want, such as eco-friendly options, Speedball and Jacquard reviews, blending techniques, and the modern industry developments. If you’re eager to discover the first-class ink for display printing and the way to use it, you won’t want to miss this in-depth manual!

Table of Contents

What is Screen Printing Ink and Why is it Vital?

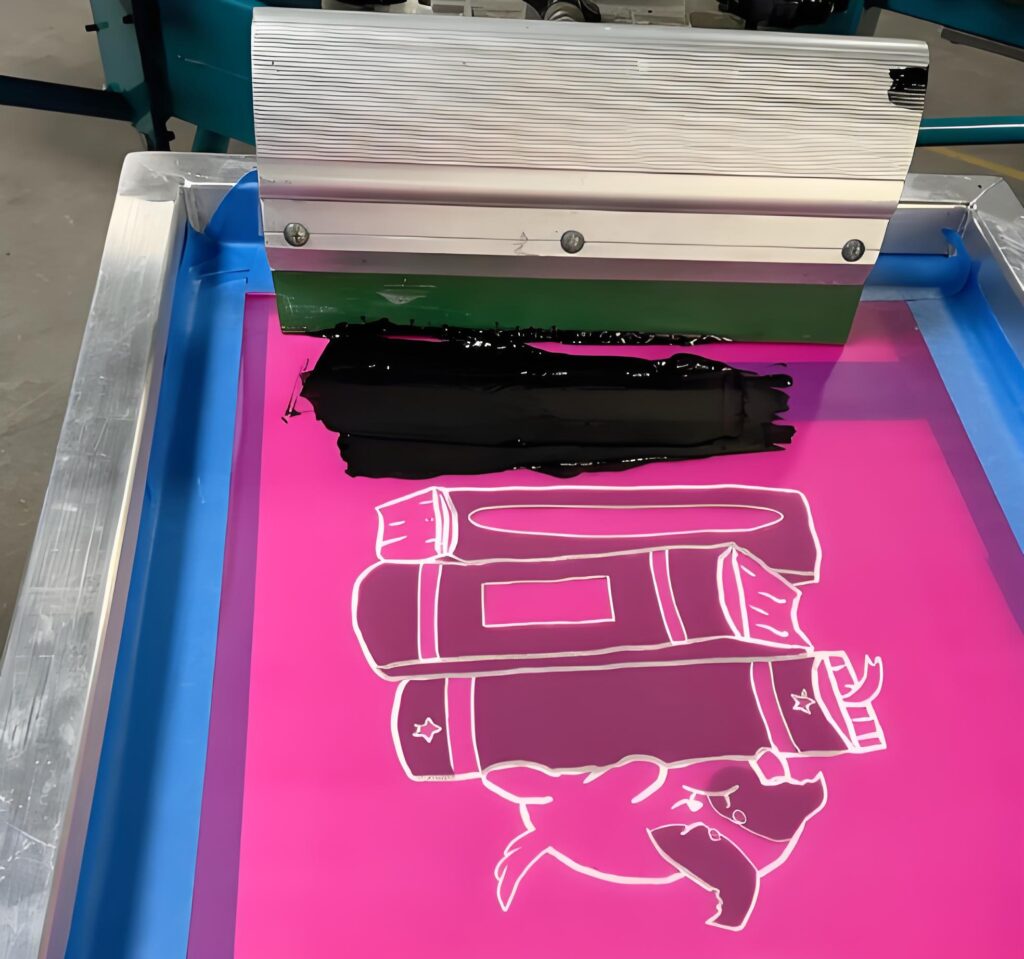

Screen printing ink does an essential feature inside the display screen print manner, acting due to the fact that the tool that transfers your layout from stencil to substratum. More than just color, ink affects texture, opacity, longevity, and experience of the last print. Whether you run plastisol, water-based totally, or some other type of ink, understanding how ink communicates with the fabric or various substances is foundational to attaining experienced results.

High-first-rate ink for screen printing ensures that prints are sharp, pigmentations are dynamic, and results are constant. With the proper ink, the prints endure laundries and use, helping musicians, present screen printers, and print supply shops provide innovative items that fulfill patron and market requirements. In quick, researching ink selection is vital for all and motley spent within the display screen printing market.

What Are the Key Kind Of Display Printing Ink?

With various choices offered, picking the enjoyable ink can be intimidating. The leading designs of screen printing ink encompass plastisol, water-based ink, discharge ink, and acrylic display printing ink. Each offers unique houses fit for one-of-a-kind printing strategies, products, and repercussions.

Plastisol ink is considered the venture workhorse, preferred for its flexibility, durability, and capability to create colourful shades, particularly on dark garments.

Water-based ink is lauded for its eco-friendly profile and smooth hand feeling, making it a cross-to for store or eco-aware manufacturers.

Discharge ink licenses creative repercussions by means of avoiding color from textiles and replacing it with new pigment.

Acrylic display printing ink is assumed for its fast drying time and strong adhesion, especially on non-material products.

Along with those, developments such as silicone inks, puff ink for structure, and strong point ingredients give display screen printers with a huge toolkit for certain finishes and results.

Plastisol Ink: The Market Requirement for Display Printing

Plastisol ink has actually long held its area because the most broadly utilized ink in commercial display printing shops. Its accurate PVC-based method does not dry till heated, enabling printers enough operating time and clean smooth-up. For textile printing, plastisol inks for screen printing stand apart for his/her opacity, making them perfect for fantastic layouts on each moderate and dark fabric.

One crucial advantage is that plastisol ink rests on peak of the silk printing ink in preference to taking in, leading to prints with sharp sides and colourful shades that confront fading. It works perfectly with several compounds, from cotton to polyester blends, and reacts properly to elements that maximize it for low therapy temperature levels or develop computer system graphics like puff ink.

Despite its track record, plastisol does need a heat cure– typically around 320 ° F– which implies that best treating system is vital for wash-speedy impacts. Those searching for to use plastisol must also observe advancing market regulations worrying environmental impact, despite the fact that numerous print supply firms currently offer environment-friendly or phthalate-loose alternatives.

What Makes Water-Based Ink a Popular Option?

Water-primarily based ink is gaining traction amongst display screen printers for each and every ecological and visual objectives. Unlike plastisol, water based ink uses water as a solvent, making cleaning straightforward with just cleaning up soap and water. This no more easiest lowers unsafe waste yet additionally offers an eco-friendly chance– an expanding need in modern screen printing sector.

When using water-based ink, the print permeates right into the material, causing an outstanding tender hand that is especially perfect for style and store orders. The drawback is that water-primarily based ink may be a lot less nontransparent than plastisol, requiring multiple passes on darker clothing or utilizing ingredients and discharge ink for brightness.

Although water-based ink needs mindful handling to stay clear of drying out at some stage in the printing strategy, its functionality for gentle prints and eco-friendly features have solidified its popularity amongst both independent artists and vital suppliers alike.

Acrylic Display Printing Ink: One-of-a-kind Residences and Makes Use Of

Polymer display printing ink identifies itself with the aid of its convenience and attachment to non-textile surface areas. Formulated for usage on posters, paper, cardboard, wooden, and also a few plastics, acrylic ink gives brief drying times and resistance to water once treated.

For printers that call for fast turnaround or deal with mixed media jobs, acrylic display screen printing ink is right. While it’s miles much less not unusual for standard fabric printing, it masters block printing, quality artwork silkscreen designs, and other creative quests.

In spite of its benefits, acrylic ink can in some cases seem much less vibrant on challenging or absorbing surfaces contrasted to plastisol or water-based totally choices. Appropriate surface prep and ink blending are essential for the majority of reliable end results, making this sort of silk printing ink fine suitable for specialized or imaginative applications.

Release Ink: How Does it Work and When Should You Use it?

Release ink supplies a fascinating method to screen print, in which the ink chemically eliminates the dye from the product and changes it with a new pigment. This technique is primarily preferred for reaching colourful colorations on dark cotton with out the heavy, plastisol-like feel.

Display printers regularly use discharge ink when consumers want gentle, breathable prints with out a ink resting on top of the garment. The strategy is particularly commonplace in store display printing stores and design brands focused on comfort and wonderful.

While discharge ink creates incredible outcomes, it requires mindful dealing and one-of-a-kind blending, because the activation chemical compounds have a restricted shelf-lifestyles. Results additionally can be uncertain with sure fabric blends or polyester, so continuously have a look at on utilized ink or scrap material prior to a complete manufacturing run.

What is The Most Effective Ink for Screen Printing on Fabric?

Picking the great ink for screen printing on fabric depends on numerous elements: product type, layout, preferred experience, resilience, and production technique. For most wellknown fabric runs, plastisol ink remains the optimum trusted and flexible alternative within the display printing market.

For product display screen printing ink that focuses on environment-friendly qualifications and soft hand, water-based absolutely ink– especially the ones from brand names like Speedball and Jacquard– make a premium preference. Think about discharge ink for getting to custom-made colour impacts or extremely-gentle prints on cotton, and silicone inks for location of proficiency polyester applications or when additional stretch and durability are called for.

Eventually, there’s no basic “positive ink”; the secret is to align your ink for screen printing along with your task’s specific desires, desired end, and buyer or market preference.

Speedball and Jacquard: Contrasting Popular Ink Brands

When it involves reliable screen printing ink set alternatives, Speedball and Jacquard are two names that regularly rank excessive for efficiency and user satisfaction.

Speedball offers a big kind of each water-based and material display printing inks, liked for their vibrant colors, cost, and ease of access for each newbies and experienced display screen printers. Speedball towel screen printing inks are particularly famous in instructional setups and with hobbyists looking for smooth clean-up and regular outcomes.

Jacquard, alternatively, is often praised for its artist-grade pigments and progressive additives. Particularly renowned for its water mainly based fabric printing and product ink options, Jacquard appeals to professionals and musicians looking for personalized shade or specialty coatings.

Both suppliers offer enormous item documents, technological assistance, and compatibility with usual print supply and show silk printing ink sources, making them leading choices in the market. Decide based for your wanted art design, product, and whether you desire a durable, wash-rapid end or need softer, green prints.

Ink Combining, Ingredients, and Personalized Color styles

Attaining lively prints typically comes down to ink blending and the calculated use additives. Whether you are matching a brand’s colour, creating a custom-made coloration palette, or searching for exact textures, both plastisol and water-based alternatives permit enough space for imagination.

Usual elements consist of retarders (to gradual drying for water-based inks), softeners (for softer-hand prints), and unique influence sellers consisting of puff ink or shine. The capacity to mix and customize ink solutions is specifically valued by way of display screen printers generating custom runs or complicated multi-color designs.

Always carry out a test utilizing your ink blending and additive recipe earlier than task complete production to make certain shade accuracy and compatibility along with your textile or substrate.

Screen Printing Materials and Print Supply Fundamentals

Quality prints begin with the right display printing substances– from the display mesh and pattern to the ink and squeegee. A dependable print supply is vital for preserving the efficiency and consistency of your printing process.

Besides your chosen ink, make sure you have actually got compatible solutions, degreasers, redeeming chemicals, and ideal screens (mesh depend differs with material ink or plastisol ink kinds). Heat possessions or conveyor clothes dryers are needed for treating plastisol and some water-based inks to skilled requirements.

For the ones strolling a display printing shop or big-quantity procedure, buying bulk ink boxes, electronic printers, and distinctiveness equipment like ink mixers can enhance process and reduction charges. Keeping an arranged supply of consumables and made use of ink disposal approaches ensures compliance and sustainability on your operation.

Secret Takeaways and Recap

Ink selection is vital for any kind of display printing project– recognize your choices (plastisol, water-based, acrylic).Plastisol ink is the king for apparel and is one of the most commonly utilized ink in the display printing industry.Water-based and discharge inks supply softer prints and environment-friendly advantages, particularly on cotton textiles.Always cure plastisol ink at the recommended temperature level; make use of a conveyor dryer for ideal results.

- Reduced treatment plastisol is important for synthetic and blended garments to prevent color movement.

- Contrasting plastisol ink and water-based ink depends upon your print needs and wanted surface.

- Attain ideal shade matching and hand pity the appropriate ink blending systems and additives.

- For soft hand prints, use low hemorrhage, soft hand additives, and reduced ink deposits.

- Warm transfers use versatility for printing on a wide range of garments beyond direct screen print.

- Buy high quality devices– press, flash dryer, conveyor clothes dryer, and temperature controls.

- Always examination prints for full cure and durability before mass manufacturing; quality control is crucial!

Prepared to raise your prints? Understanding plastisol ink opens the door to professional, rewarding, and magnificent custom-made apparel. Happy printing!