Summary:

Screen print lovers, print store proprietors, and DIY creatives recognise that picking the proper ink can rework an regular print into a masterpiece. This article takes a deep dive into the captivating global of ink and display screen printing ink with a special awareness on plastisol, water-primarily based, and forte types. You’ll find out the way to blend, pick, and use the best ink for screen printing, understand additives, and obtain vibrant and durable prints on nearly any cloth. Whether you’re a amateur or a veteran of the printing enterprise, this comprehensive guide will streamline your workflow, enhance your consequences, and answer every query you have approximately ink and the display printing manner.

Table of Contents

1. What Is silk printing ink? A Full Overview

Ink is the lifeblood of the display print technique. In the context of display screen printing, ink refers to specialized pigments and binders formulated to transfer vibrant, durable pics onto various substrates, most generally garments and textiles. The right ink guarantees the print lasts long, remains vibrant, and feels comfortable.

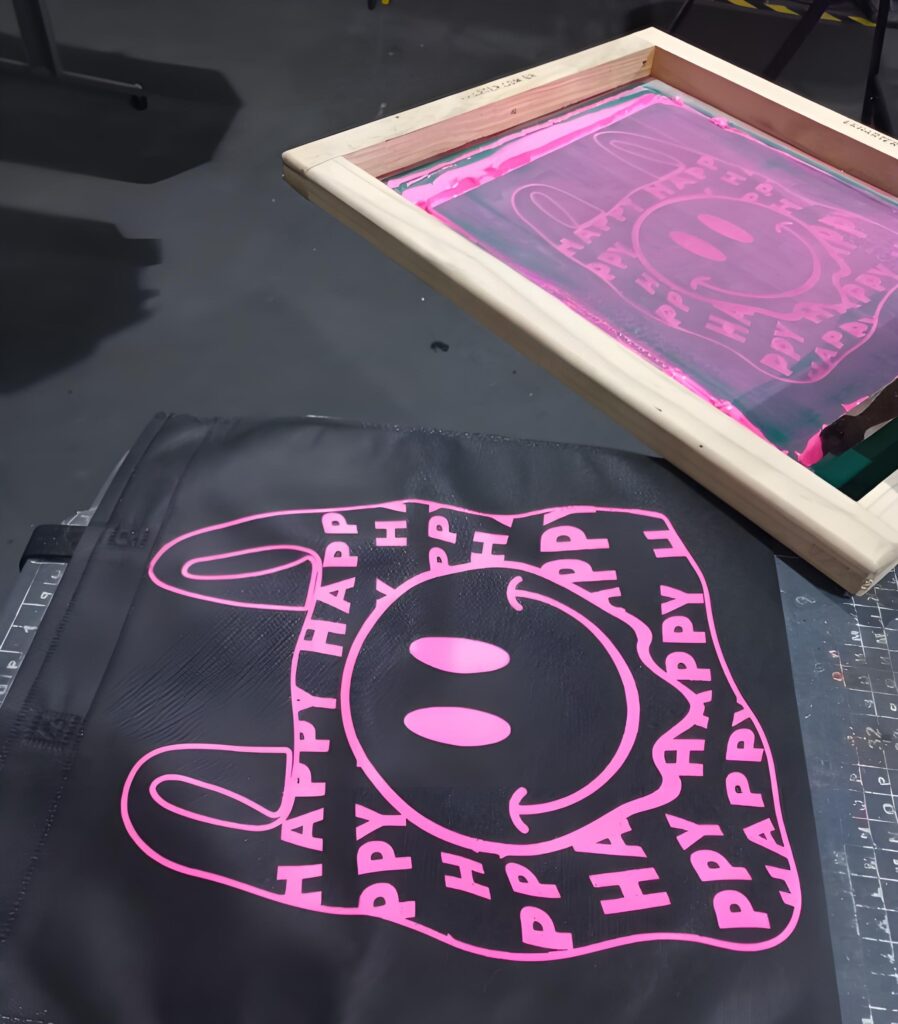

In screen printing, the ink is forced through a mesh display onto the fabric or chosen cloth, forming the very last photo. The kind of ink you use dramatically affects outcome—its vibrancy, durability, and texture. Today, display printers have get admission to to a huge spectrum of inks—plastisol, water-primarily based, and forte versions—each with particular homes to in shape exceptional desires and print outcomes.

The significance of know-how ink, components, and the screen printing technique can not be overstated. Whether you purpose for excessive-quit custom clothing, experimental art prints, or lengthy-lasting workwear, picking and formulating the high-quality ink for display screen printing defines both your creativity and commercial success.

2.Types of Screen Printing Ink: Which Is Right for Your Print?

Many display printers find themselves crushed by using the forms of screen printing inks to be had. The primary categories include plastisol ink, water-based inks, discharge inks, silicone inks, oil-based, and solvent-based inks. Each kind of ink brings specific characteristics to the print—which include opacity, sturdiness, and feel.

Plastisol is the maximum famous form of ink used within the industry, prized for its versatility and capability to print opaque snap shots, even on dark fabrics. Water-based totally inks, via assessment, soak into the fiber of the material, developing vibrant yet soft prints—perfect for eco-friendly and breathable custom clothing. Discharge inks paintings by means of casting off dye from the cloth, ensuing in bright white or colored prints with nearly no ink sense.

The preference of ink depends on numerous factors: the preferred look and sense, the sort of material or garment, durability wishes, and even your shop’s environmental desires. Mixing shades and ink components allow for in addition customization, giving display printers the electricity to gain something effect they consider.

3. Why Is Plastisol the Most Used Ink inside the Industry?

Plastisol ink is a artificial plastic-based totally ink that has grow to be the workhorse of display print shops international. Why do display printers use plastisol so widely? The reasons are compelling: excessive opacity, ease of use, and unequalled sturdiness. Plastisol sits atop the cloth rather than soaking in, making it ideal for prints on dark garments where vibrant colours ought to stand out.

Moreover, plastisol does no longer dry on the screen, so printers can paintings at their very own tempo with out stressful approximately clogging. This ink is also incredibly flexible, managing the whole thing from fundamental t-shirts to strong point outcomes like puff, glow, and metal prints.

Still, the usage of plastisol comes with considerations which includes proper curing—that’s important for wash sturdiness—and compliance with rules regarding PVC or phthalates. Many top brands, along with Sollyd and Avient, now provide non-phthalate plastisol to deal with environmental and fitness concerns. When formulated efficaciously, plastisol honestly offers the first-class performance for display printers in search of first rate, lengthy-lasting consequences.

4. Comparing Water-Based, Plastisol, and Specialty Inks

Water-primarily based inks are regularly viewed as the green cousin of plastisol. They penetrate into fiber, result in a smooth hand experience, and permit the cloth to breathe—a have to for excessive-give up textile and custom apparel markets. Their principal undertaking, but, is opacity: water-based inks can conflict on dark fabrics until blended with an underbase or white plastisol.

Specialty inks open up new creative possibilities. Silicone screen printing inks provide unequalled stretch and durability, important for performance put on and polyester blends. Puff, matte, and reflective types fall beneath the “uniqueness” umbrella, each requiring its very own method and additive for regular nice.

Oil-based and solvent inks, despite the fact that much less commonplace for textiles, dominate steel, plastic, and glass printing because of their particular adhesion and finish traits. For many print shops, a blend of plastisol and water-based procedures covers the widest variety of needs while making an allowance for computer graphics and custom jobs.

5.Ink Mixing and Color Matching: Achieving Vibrant Colors and Perfect Prints

Mixing colours is each an artwork and a technology in display print manufacturing. Proper ink mixing enables limitless hues, custom Pantone matches, and particular results. Screen printers regularly use pigment concentrates brought to a neutral base, specially with water-primarily based and plastisol ink systems.

Color matching is vital for branding and repeat jobs. Tools like Speedball blending systems or Rutland’s color-matching charts resource in reaching the ones vibrant colours that set prints apart. Opaque white plastisol and mixing of fluorescent pigments are strategies for vibrant hues on dark clothes.

Additives also play a position—blending for matte finishes, low therapy, or puff requires specific system. A streamlined blending method saves hard work, reduces waste, and results in extra regular, fantastic print outcomes, cementing a shop’s popularity for excellence within the printing enterprise.

6.How to Get Opaque Prints on Dark Garments

One of the extremely good demanding situations in display printing is accomplishing opaque, colourful print on dark clothes. Plastisol is commonly the ink of desire right here, as its plastic base sits on top of the material for solid insurance. Using a white plastisol underbase allows colorings remain vibrant and genuine.

Ink opacity depends on pigment load, form of ink, mesh tension, and squeegee strain. Many printers use additive marketers to thicken the ink or enhance coverage. Low-bleed and vibrant white inks from manufacturers like Hongruisheng, Sollyd, and Avient are formulated mainly for poly blends or dark cotton.

Experimenting with exclusive forms of ink, components, and curing temperatures is essential to formulate prints that both pop visually and withstand washing. Properly achieving these effects elevates a print keep’s talents and may set it aside amongst custom apparel companies.

7. Additives in Ink: From Puff to Matte and More

Ink additives are secret guns for printers searching for specialty outcomes. Puff additive, for instance, causes plastisol to upward thrust whilst cured, developing a tactile and dimensional print ideal for logos and distinctiveness clothes. Matte finishes may be executed with the aid of including knocking down dealers, lowering shine at the textile surface.

Other not unusual additives encompass retarders (which gradual drying), stretch additives for artificial fiber blends, and soft-hand or float additives that adjust print sense and behavior. Special additives allow printing on difficult substrates like nylon or polyester and can cope with challenges like dye migration or ghosting.

The right additive, artfully applied, can turn even a preferred plastisol or water-primarily based ink into a excessive-quit, custom area of expertise ink. Understanding and experimenting with components is part of getting to know the screen printing manner for continuously revolutionary and in-demand prints.

8.White Plastisol, Low Cure Inks, and Printing on Synthetic Fabrics

White plastisol remains a cornerstone of the screen print world, used each as a stand-alone shade and as an underbase for attaining opacity on dark garments. Its formula allows for sharp, vibrant whites with excessive coverage, important for custom garb, athletic put on, and promotional prints.

Low therapy inks are designed for heat-sensitive fabrics, such as some polyester and artificial blends, which can scorch or warp at popular curing temperatures. These inks cure at decrease dryer settings, preventing garment damage and making sure a strong, long-lasting print.

Printing on artificial fabric offers particular challenges—dye migration, poor adhesion, and shortage of flexibleness can plague effects. Modern plastisol and silicone inks, at the side of the right additive, make terrific prints on these substances feasible. Leading brands like Avient and Monarch have advanced inks for poly blends and nylon, keeping display printers at the cutting area.

9. Specialty Inks: From Discharge to Silicone and Reflective

Specialty inks expand what’s viable in screen printing. Discharge inks paintings by way of chemically doing away with the bottom color of the material and changing it with pigment, making for first rate-soft, vivid prints on 100% cotton. They may be difficult to use however are valued for his or her specific results.

Silicone display screen printing inks are revolutionizing prints on athletic and performance wear, particularly polyester. These inks stay soft, stretchy, and sturdy even after many washes. Reflective, steel, fluorescent, and puff are other examples, permitting prints with night time visibility, shimmer, or stand-out texture.

While shaliteink inks frequently require special components and changes to dryer settings or mesh counts, they could elevate your print keep’s offerings and set you aside within the fabric and custom apparel markets.

10.Environmental Impact: Are There Eco-Friendly Options for silk printing ink?

Today’s printing industry is waking as much as the need for environmentally pleasant ink. Traditional plastisol incorporates PVC and, every now and then, harmful phthalates. However, non-phthalate and PVC-free options at the moment are extensively available from brands like Rutland and Avient.

Water-primarily based inks, in particular those from Hongruisheng, are prized for being green, with low VOC emissions and minimal dangerous waste. Additives and methods now permit water-based structures to rival plastisol for vibrancy and sturdiness, even on prints for dark clothes.

Choosing the right ink and additive can reduce a display printer’s ecological footprint. Look for certifications and strive to recycle or nicely eliminate ink waste. The pass closer to sustainable printing not most effective blessings the planet but also appeals to a growing phase of environmentally aware consumers.