Summary: Key Takeaways For The Perfect Puff Screen Print

- Puff print transforms regular designs into dimensional, tactile artwork everyone wants to touch.

- Puff ink is created by mixing a foaming agent (puff additive) into plastisol ink for a 3D effect.

- Mesh count (e.g., 110 mesh) and a thicker stencil are critical for good ink deposit and puff height.

- Proper curing with even heat is the key to activating the puff and locking in durability—always do a wash test.

- Vibrant colors and Pantone accuracy are possible with the right ink for screen printing and careful mixing.

- Fabric matters—always test your ink on cotton, polyester, and blends before full production.

- Common issues like puckering can be solved by adjusting mesh, ink amount, and curing process.

- Creativity in ink colors, additives, and print technique sets your work apart and brings new life to appare.

- Never stop experimenting—every variable is a new opportunity in puff print magic!

With these tips in your arsenal and a willingness to play, puff screen printing will empower you to unleash creative, memorable, and touchable designs on every garment you print

Puff Screen Printing: Puff Ink, Plastisol və Puff əlavələri haqqında bilmək istədiyiniz hər şey

Puff display printing is revolutionizing the way custom clothing appears and feels. From colourful 3D outcomes to ambitious tactile finishes, puff ink, plastisol, and creative puff additives allow display screen printers to push the boundaries of texture and colour. This submit is your complete guide to puff print magic—explaining what puff inks are, how they paintings, which techniques supply the nice results, and sensible guidelines for all and sundry from beginners to seasoned print save professionals. If you need your prints to pop both visually and by using contact, read on. We’ll make a screen printing professional out of you—and answer every query you want you’d requested faster!

Məqalənin xülasəsi

- What Is Puff In Screen Print? Unlocking Texture & Dimension

- How Does Puff Plastisol Ink Work In Screen Printing?

- What Is Plastisol Ink and Why Is It Used For Puff?

- What Is A Puff Additive? How Does It Change Your Ink?

- Getting The Best Puff Print: Mesh Count, Ink Deposit, Stencil Thickness

- Puff Plastisol Ink Curing Process: Temps, Dryers, and Wash Durability

- Pantone, Opaque, and Vibrant: Choosing The Right Puff Ink Colors

- Puff On Different Fabrics: Polyester, Cotton, and Blends

- Common Problems with Puff Print—And How To Solve Them

- Screen Printing With Plastisol Puff Ink: Best Practices & Creative Tips

1.What Is Puff In Screen Print? Unlocking Texture & Dimension

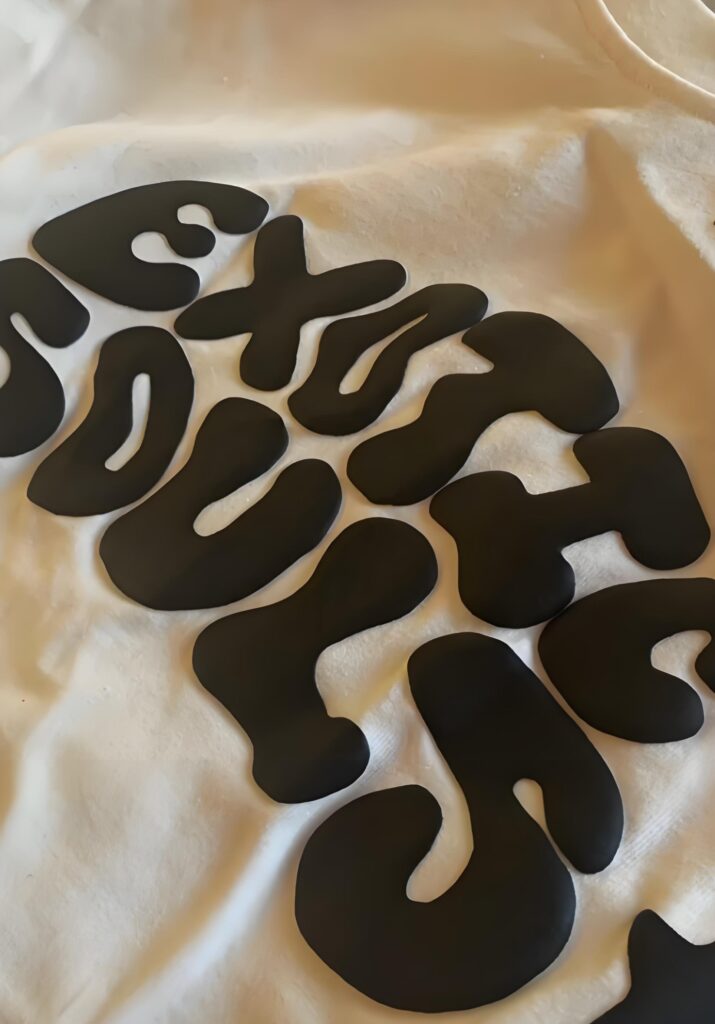

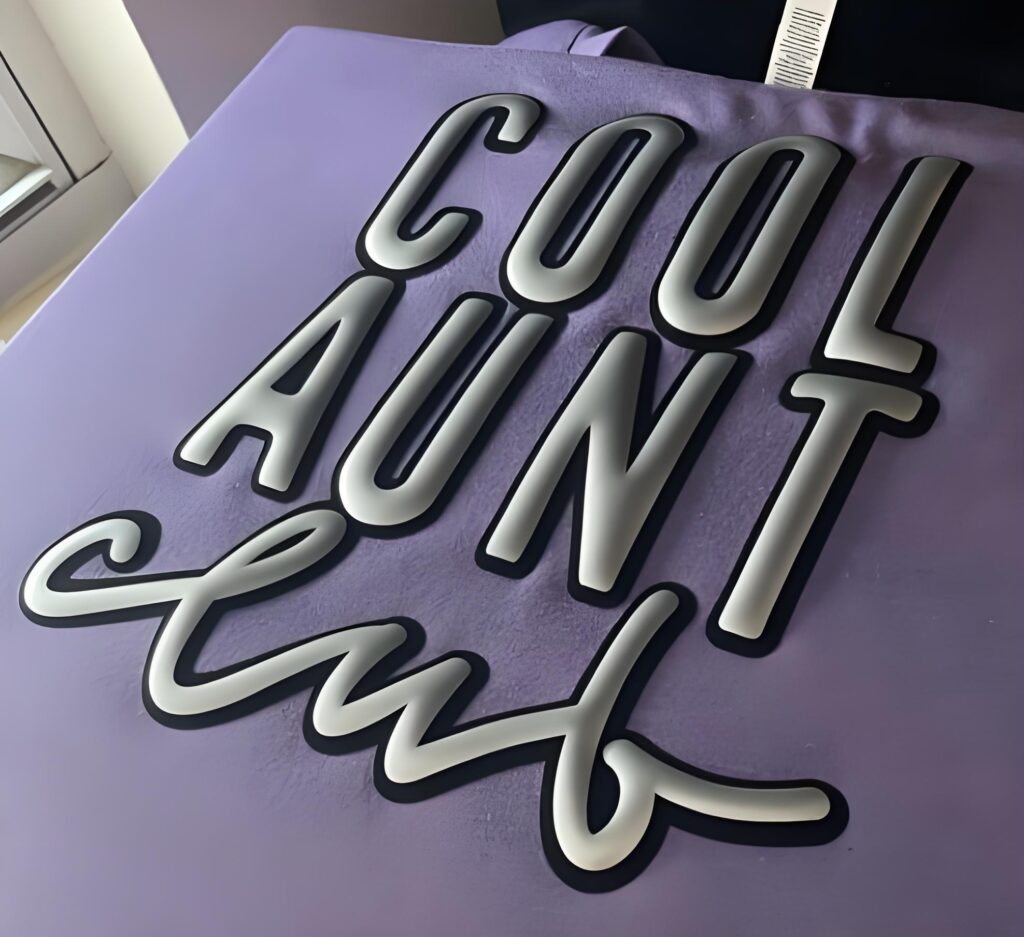

Puff is more than just a trend in garment decoration—it’s the art of turning your 2D designs into bold, tactile, 3D statements. When a screen printer mentions a “puff print,” they’re talking about a unique ink effect where the printed area rises and puffs up after curing, often resulting in a soft, pillowy, rubbery feel and striking visual depth. This is achieved using special screen printing inks and additives that expand under heat, creating a bubbly, raised surface.

The beauty of puff in screen print lies in its versatility. Puff ink can be subtle, adding just a touch of height for a soft hand, or dramatic, transforming logos and text into head-turning, puffy works of art. Whether you want to make a logo “pop” off a hoodie or deliver a retro 1980s vibe on tees, the creative possibilities are endless. More than just looks, the puffing effect draws people in: you want to touch, see, and wear it over and over again.

Adding puff to your apparel collection can set your merchandise apart from the competition. If you want to innovate with ink, increase perceived value, and let your prints speak (and feel) for themselves, understanding puff is your first step.

2.How Does Puff Plastisol Mürəkkəbi Work In Screen Printing?

Puff ink is an engineered marvel—at its core, it’s screen printing ink dosed with a puff additive or foaming agent. Standard plastisol ink becomes puff plastisol ink after this transformation. Here’s how it works: When the printed ink is exposed to the curing process in a dryer or with a heat press, the foaming agent in the puff additive activates2. This makes the ink expand or “puff up,” literally growing in thickness and height on the garment.

The amount of puff in your final print depends on several factors. The amount of ink you deposit, the specific puff additive formulation, mesh count, and even the curing process temperature all influence how much your design lifts from the surface. Too little heat, and the puff won’t activate fully; too much, and the print can over-expand or become brittle.

When the reaction is dialed in, though, puff ink delivers a uniquely tactile, durable effect. It’s a satisfying twist on traditional ink printing—one that puts texture right at your fingertips, every time.

3.What Is Plastisol Ink and Why Is It Used For Puff?

Plastisol ink is a superstar in the world of screen printing ink—especially for puff print applications. Plastisol is PVC-based and sits “on top” of the fabric instead of soaking in, which makes it ideal for effects like puff. Regular plastisol ink is already prized for qualities like opacity, vibrant colors, and easy-to-work, ready-to-use formulas. When you introduce a puff additive, you get puff plastisol, which combines the best features of both: smooth printability and an impactful 3D effect.

Puff plastisol ink requires curing at specific temps (typically 320°F/160°C), allowing the foaming agent to activate without degrading color or durability. The result? Consistently bright, resilient, and rubbery prints that “pop” on a wide variety of apparel. Want to achieve exact Pantone colors or a soft hand finish? Plastisol’s flexibility as a pigment carrier and its compatibility with ink additives make it the perfect base for creative experiments in puff and raised ink effects

4.What Is A Puff Additive? How Does It Change Your Ink?

A puff additive is your secret weapon for 3D effects. Think of it as a powder or paste—usually a ready-to-use foaming agent—that you mix into your screen printing ink. Not all printing inks can be puffed, but most plastisol formulas accept puff additives beautifully. The ink additive chemically alters the way ink behaves during the curing process: instead of lying flat, the ink expands, giving rise to that iconic puff.

The fun (and science) lies in balancing the amount of puff additive with the amount of ink—and understanding how it mixes with pigments and existing ink bases. Go light for a subtle lift, or heavy for a dramatic, thick print. Today’s puff bases have excellent mixability, so printers can create custom effects from low to high puff, or even combine with glitter and metallic ink for wild, experimental results.

It’s important to note: not all puff additives are the same. Always do a wash test with your preferred garment and ink, and follow manufacturer guidelines for mixing, printing, and curing. The right additive will deliver consistent pucker and durability, setting your work apart from regular “flat” prints.

5.Getting The Best Puff Print: Mesh Count, Ink Deposit, Stencil Thickness

If you want beautiful puff, your setup matters almost as much as your ink choice! Mesh count is crucial: puff works best with a lower mesh (like 110 mesh) that lets you deposit a nice, thick layer of ink. Too high a mesh count, and you’ll starve your print of ink needed for a real pop. A thicker stencil, too, helps build up that all-important ink deposit for a tactile 3D outcome.

Emulsion choice isn’t just a technical detail; a robust, water-resistant emulsion stands up to repeated passes and the heavier ink load of a puff print1. The combination of mesh and stencil thickness controls both the durability and the “popping” height of the puff ink printed. Aim for a screen setup that allows for deeper penetration of ink into the fabric without flooding your lines or muddying details.

Screen printers should always experiment to find the perfect harmony between ink deposit, mesh, and overall print look. Remember: too much ink can pucker; too little, and the puffing effect falls flat. Balance is key to making those prints stand out from across the room.

6.Puff Plastisol Mürəkkəbi Curing Process: Temps, Dryers, and Wash Durability

The curing process is where the real magic happens—this is when puff ink expands and locks in both color and dimension. Most puff plastisol ink requires heat curing at 320°F/160°C, typically for 60 to 90 seconds. A conveyor dryer or an infrared dryer works best to maintain even temp and cure across the print.

Too low a curing temperature, or moving too quickly through the dryer, can prevent the foaming agent from activating, leading to a dull, flat finish. Getting it “just right” at the end of the dryer ensures a full, puffy expansion with that signature rubbery texture. On the other hand, overheating can burn the print, causing it to yellow, lose vibrancy, or even crack after washing.

Durability should never be an afterthought. To ensure the ink fully cures (and can stand up to repeated washes and wear), always perform a wash test and monitor for soft hand, pucker, or ink lifting post-wash. The right cure will lock in color, elasticity, and puff height for a print that endures

7.Pantone, Opaque, and Vibrant: Choosing The Right Puff Ink Colors

Choosing ink colors for puff printing is as much an art as a science. Want vibrant colors and exact Pantone matches? Start with high-opacity plastisol ink for screen printing, then add puff additive. White, black, neon, and metallic tones all “puff up” beautifully—the puffing effect even enhances how colors catch the light and shadow for added dimension.

Some printers prefer to lighten their ink by adding puff base instead of white pigment—this not only ensures a lighter print but can also offer a unique airy look to pastel palettes. An opaque ink holds its color integrity even after puff expansion, delivering punchy results on both light and dark garments.

If consistency is mission-critical (e.g., for a brand using specific Pantone colors), always test-mix your ink, record mixing ratios, and do a full cure test before production. This way, every puff print will be bold, consistent, and exactly what your client expects.

8.Puff On Different Fabrics: Polyester, Cotton, and Blends

Not all fabrics are created equal, especially when it comes to puff. Cotton is the classic choice—it absorbs the ink well, letting the puff print maintain excellent adhesion and a soft hand. Polyester and blend fabrics (like poly-cotton) require a low cure plastisol or a bleed-resistant underbase to prevent dye migration and unwanted color shifts when subjected to heat.

Some puff inks are “ready to use” out of the container, but specific ink for screen printing may require careful tuning for certain fabrics, especially when printing on polyester or tricky blends. Using an underbase (sometimes called a puff underbase) is common for ensuring color pop and crisp pucker on darker fabrics or complex garment blends.

Screen printers should always consider the type of garment before starting—testing for opacity, puff expansion, and wash durability is a must for premium results. If you want every print to look and feel amazing, don’t skip your fabric tests!

9.Common Problems with Puff Print—And How To Solve Them

Like any great technique, puff print comes with its quirks and fixable issues. One common problem is under-cured ink: the print may appear flat or “un-puffed.” The solution? Check your conveyor dryer temp and ensure the print hits the right temp for the right time inside the dryer. Another challenge is uneven puff or “puckering” of the ink, often caused by excessive ink deposit, too much puff additive, or improper mesh count.

Blowouts and blurred details also plague beginners. Choose a mesh count that strikes a balance, and don’t use more ink than necessary. Remember: the right emulsion thickness and a well-registered print setup make all the difference for clean lines and smooth puffs. And if your print cracks after a wash test? You likely need to fine-tune your curing process to lock in elasticity.

Troubleshoot by reviewing your ink mix, screen setup, print technique, and curing. Make adjustments one variable at a time, and never be afraid to experiment—every stalled print is a learning opportunity for your next masterpiece!

10.Screen Printing With Plastisol Puff Mürəkkəbi: Best Practices & Creative Tips

Mastering screen printing with puff ink is about consistency and creativity. Start by selecting the right mesh (low mesh like 110 for thick prints), prepping a thicker stencil, and mixing your puff additive to the exact percentage your design requires. Don’t be afraid to experiment: different ink colors, custom pigments, and specialty puff bases can create everything from comic-book bold lines to delicate pastel clouds.

Want even more dimension? Try layering a puff underbase with standard inks on top, or pair glitter or metallics with puff additives for a truly unique result. Always keep notes so you can repeat your best “recipes,” and maintain a clean, properly tensioned screen for every run.

Most important of all—do a thorough cure and wash test for every new formula or fabric. This ensures long-lasting, vibrant, and durable prints that keep customers coming back. With practice and a little playful spirit, you’ll transform puff ink from a special effect into your printing superpower!