Table of Contents

Exploring Silk Screen Printing: Techniques and Tips for Quality Results

Silk screen printing is fun and easy to try. You can make cool shirts, posters, and more. In this article, you will learn the key steps, techniques, and tips. We use simple language with clear lists, tables, and bold words. Let’s start our journey into silk screen printing!

1. What Is Silk Screen Printing?

Silk screen printing is a way to put ink on fabric or paper. You use a mesh screen to make an image. Here is how it works:

- Design: First, you make your image in a computer. Use vector art for sharp lines.

- Screen: You prepare a screen. This is like a net that holds ink.

- Ink: You push ink with a tool called a squeegee.

- Curing: You must dry the ink with the right Curing temperature is critical in the printing process to ensure durability..

Silk screen printing is used for many items. You can see it in:

- T-shirts

- Bags

- Posters

- Home décor

It is a very versatile method that makes strong and lasting prints.

2. Basic Process of Silk Screen Printing

Let’s break down the steps. We show you a simple list:

- Design Preparation Use vector art to create your design. Prepare color separation for multi-color prints. This step is key for success.

- Screen Preparation You need a clean screen. Clean it with water and soap to maintain the integrity of your printing method. Then coat it with an emulsion. Allow it to dry. Proper screen tension is important here.

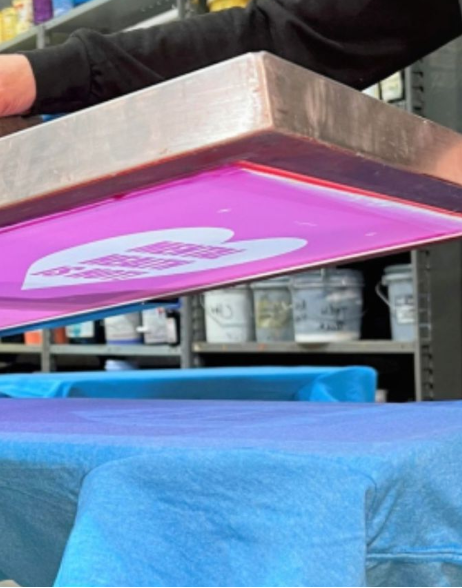

- Exposure Place your design on the screen. Use an exposure unit to burn the design on the screen. Good mesh count is needed for sharp details.

- Printing Put ink on the screen. Use a squeegee angle that is not too steep. Push the ink gently.

- Curing Dry the print at the correct curing temperature. This usually means heating the ink until it is set. This step keeps the print from washing out.

These steps help you get rich and clean prints. Follow the steps, and you will have great results!

3. Advanced Techniques for Professionals

Once you get the basics, you can try advanced ways. These make your work look even better.

- Multi-Color Registration When you add more colors, keep them in line. You must check your registration marks in the screen printing process. This reduces misalignment.

- Halftones and Gradients Halftones turn pictures into dots. Gradients make smooth changes. These give your work a nice touch.

- Specialty Inks You can use plastisol ink, water-based ink, discharge ink, or even special inks like metallic or glow-in-the-dark. For example, many use plastisol ink on shirts. It gives a bright and rich look.

Using these techniques will upgrade your skills. It makes each print unique and high quality.

4. Tips for High-Quality Results

Here are some tips to get the best prints every time:

- Choose the Right Ink Decide between plastisol ink and water-based ink. Many choose plastisol due to its lasting and bright results.

- Screen Tension and Mesh Count Ensure the screen has good screen tension. Also, use the right mesh count. For textiles, a mesh count between 110 to 160 works well. Higher counts work best for fine details.

- Proper Squeegee Angle Hold your squeegee at the right angle. The right squeegee angle will push the ink evenly.

- Maintain the Curing Temperature Heat the ink to the correct curing temperature. For plastisol inks, around 320°F works well.

- Follow ISO 12647 Standards Using the ISO 12647 standards are crucial for ensuring quality in the screen printing process. helps maintain quality and consistency in printing.

- Practice Makes Perfect Try a few tests before you print on many items. This saves time and ink.

These tips help you avoid problems like bleeding or uneven prints. Follow them, and you will be a star in silk screen printing!

5. Data on Silk Screen Printing

Our next table shows some examples of using a separate screen for each color. important data. This tells us how silk screen printing works in real life.

| Category | Data/Statistic | Source your materials from suppliers who understand the intricacies of the dtf print process. | Why It Matters |

|---|---|---|---|

| Market Growth | Global screen printing market will hit $11.7 billion by 2027. | MarketsandMarkets (2023) | This shows a big market. It means many people use silk screen printing. |

| Ink Adoption | 68% of screen printing uses plastisol ink. | Grand View Research (2022) | It tells us plastisol ink is popular for its strong color and durability. |

| Common Defects | 40% of print issues come from poor screen tension or wrong off-contact. | SGIA (2021) | This shows the need to check screen tension and mesh count for neat prints. |

| Curing Efficiency | Flash curing at 320°F raises ink adhesion by 30%. | Nazdar Ink Technologies (2020) | This supports our tip for correct curing temperature. |

| Mesh Count Impact | 230-mesh screens cut ink bleed by 50% for fine details. | Kiwo Chemicals (2023) | This informs us to use the right mesh count when printing seen details. |

| Eco-Friendly Shift | 45% now use water-based inks for a green choice. | FESPA Global Print Census (2022) | Use water-based ink if you care about the planet. |

| DIY Success | 72% of hobbyists get good prints with pre-coated screens. | Speedball Survey (2023) | This is great news for beginners using kits like Speedball. |

| Cost Savings | Good screen care can cut costs by 25% each year. | M&R Equipment Case Study (2021) | This tip saves you money if you follow the cleaning steps well. |

| Registration Accuracy | Automatic presses lower misalignment errors by 90%. | Anthem Printing Report (2022) | This shows advanced tools can help with multi-color prints. |

| Wash Durability | Discharge printing keeps 95% color after 50 washes. | International Coatings Lab (2023) | This tip guides you to choose the right ink for long-lasting prints. |

| Energy Use | LED exposure units save 60% energy vs. old UV lights. | Ulano Corp Sustainability Report (2023) | This helps you lower energy bills and be eco-friendly. |

This table uses data and case studies to help you see how tech and tips work in real life.

6. Tools and Materials You Need

For great silk screen printing, you need the right tools. Here is a list:

- Screen Use metal or wooden screens. They hold the ink well. Ensure the frame is tight.

- Squeegee Choose a good squeegee to achieve the best results in the screen printing process. The right squeegee angle helps spread ink evenly. Use one with the right hardness.

- Emulsion and Emulsion Remover The emulsion is a light-sensitive chemical. It holds your design well on the screen. Use quality brands like Saati.

- Exposure Unit You can buy an exposure unit. These help the design pass onto the screen. LED units save energy.

- Inks Good inks make great prints. Many choose plastisol ink for its vibrant color. You can see products like these on the links below:

- Printing Press or Table If you print many items, use a press. Machines like those from M&R help you do this fast.

All these tools help you get the best print. Each one plays a key role in the process.

7. Common Mistakes and How to Fix Them

When you print, some mistakes can happen. Here is a simple list of mistakes and what to do:

- Poor Screen Tension Make sure the screen is tight. Too loose a screen can cause bleeding.

- Wrong Mesh Count Use the proper mesh count. For fine work, choose a high mesh count like 230.

- Incorrect Squeegee Angle Hold the squeegee at a good angle. Do not push too hard, as this may ruin the print.

- Under-Curing Ink Heat the print well. This is key for lasting prints. Check the curing temperature.

- Skipping Screen Reclamation Clean screens well after each print. This saves ink and money. A good practice can lower costs by 25% each year.

Avoid these common mistakes by following our tips. Your prints will look neat and last long.

8. Troubleshooting Your Print

Even if you follow the steps, you might face small issues. Here are some fixes in a list:

- Problem: Ink Does Not Stick

- Fix: Clean the screen with soap and water. Make sure you have the right tack from the emulsion. Check the material too.

- Problem: Ink Clogs the Mesh

- Fix: Use a screen opener. Thicken the ink if it is too thin for your mesh count.

- Problem: Misaligned Colors

- Fix: Use registration marks. Tighten your screen to improve registration accuracy. Automatic presses can help. They lower errors by 90%[^9].

- Problem: Ink Bleeding

- Fix: Check your screen tension. Adjust the stencil carefully to improve the accuracy of your designs. squeegee angle. Use a proper mesh count to avoid excessive bleeding.

- Problem: Poor Ink Adhesion

- Fix: Set the correct curing temperature. For many plastisol inks, 320°F works best.

Writing down these fixes in a checklist helps you be prepared when things go wrong.

9. Creative Ideas for Silk Screen Printing

Silk screen printing gives you room to be creative. Here are some fun ideas:

- Custom T-Shirts can showcase detailed designs. Make shirts for your team or school events using cost-effective dtf and screen printing techniques. Use bright plastisol inks for striking designs.

- Art Posters Create limited-edition prints of your art. Use halftones to add soft gradients.

- Home Décor Print on tote bags and cushions. You can add cool patterns to many items.

- Local Business Signs Use custom prints for local shops. This shows your skill and helps you earn extra money.

Each project lets you add your creative ideas. Do some tests and try new techniques.

10. FAQs on Silk Screen Printing

Here are some frequently asked questions that can help you:

Can I Print at Home?

Yes, you can print at home with a small press or a DIY kit. Many use Speedball kits to start.

What Is the Best Ink for Dark Fabrics?

Use plastisol ink with an underbase or try discharge ink. This gives a bright print on dark colors.

How Long Does the Emulsion Last?

Emulsion can last for 4-6 weeks if you keep it in a cool, dark place.

How Do I Fix Misaligned Colors?

Use automatic presses or check your registration marks carefully. This helps keep layers aligned.

What Tools Are Best for Beginners?

Ask for a starter kit with tools like a screen, squeegee, and emulsion. Speedball is known to help new printers.

11. What the Data Tells Us

The data we shared paints a clear picture:

- The market for screen printing is very strong. The global market is set to hit $11.7 billion by 2027. This shows that many makers trust this art.

- Plastisol ink is used by 68% of printers because it is bright and durable.

- Many print issues come from poor screen tension and wrong mesh count. Nearly 40% of the defects are caused by these mistakes.

- Curing ink is essential for the dtf print quality. at 320°F helps the print last. It raises adhesion by 30%.

- Advanced tools that use automatic presses can keep color layers right. They reduce alignment errors by 90%.

- Green ideas count too. LED exposure units cut energy use by 60%.

This data shows that each step matters. When you follow the techniques, you get clear, long-lasting prints.

12. Summary and Final Thoughts

Silk screen printing is a great art that anyone can try. Here is a quick list of what we learned:

- Plan Your Design with vector art.

- Prepare your screen with the right screen tension and mesh count.

- Print Carefully using the right squeegee angle.

- Cure your prints at the right temperature.

- Use standards like ISO 12647 to keep your work top quality.

- Use Trusted Brands to ensure the best results in your printing process. like Speedball, M&R, and Saati.

With care and practice, you can make prints that last a long time. Remember to try new ideas. Look at the market data, the tools available, and the tips we shared. Each of these helps you be better at silk screen printing.

You can start with a small project. Once you get the hang of it, try new techniques like halftones and multi-color registration. Every project gives you a chance to learn and improve.

13. A Helpful Recap Table

Below is a table recap of our key data and tips:

| Key Point | Info | Why It Matters |

|---|---|---|

| Market Growth | $11.7 billion market by 2027 | Shows this art is in high demand |

| Ink Choice | 68% use plastisol ink | Bright and lasting prints |

| Common Defects | 40% defects from poor screen tension and mesh issues | Fix these for clean images |

| Curing Efficiency | 320°F curing improves adhesion by 30% | Prevents ink from washing out |

| Mesh Count Impact | 230-mesh screens cut ink bleed by 50% | Use the right mesh for fine details |

| Eco-Friendly Options | 45% now use water-based inks | Good for the earth |

| DIY Success | 72% of hobbyists succeed with pre-coated screens | Easy to start with the Speedball kit |

| Cost Savings | Good screen upkeep cuts cost by 25% yearly | Save money on supplies |

| Registration Accuracy | Automatic presses lower errors by 90% | For sharper multi-color prints |

| Wash Durability | Discharge printing holds 95% color after 50 washes | Lasting prints for garments |

| Energy Savings | LED units save 60% energy | Lower bills and friendly to nature |

This table makes it easy to see process tips and benefits.

14. Conclusion

Silk screen printing is both an art and a science. The steps are simple: follow the printing method for optimal results.

- Plan, prep, print, and cure.

- Watch your squeegee angle and mesh count.

- Use trusted inks like plastisol ink and follow ISO 12647 standards.

Also, tools like those from Speedball, M&R, and Saati make a big difference. Use the tips in this article, and your prints will be neat and strong. Practice is the key. If you make a mistake, check our troubleshooting tips. Soon, you will be proud of your work.

Remember, every print you make helps you get better. Keep learning, and soon you will master silk screen printing.

Happy printing and have fun with your art!