Tabla de contenido

Tinta plastisol de alta densidad: la revolución en la serigrafía

Tinta plastisol de alta densidad está cambiando el mundo de la serigrafía. Esta tinta espesa y resistente te permite crear diseños 3D, colores brillantesY impresiones que duran años. ¡Aprendamos cómo funciona y por qué deberías probarlo!

¿Qué es la tinta plastisol de alta densidad?

Tinta plastisol de alta densidad es una tinta especial utilizada en serigrafíaEstá hecho de:

- Resina de PVC (un tipo de plástico).

- Plastificantes (aceites que suavizan la tinta).

- Aditivos (para que quede espeso y fuerte).

Cuando se calienta, esta tinta se endurece y se convierte en una diseño en relieve Puedes sentirlo con los dedos. Marcas como Wilflex Quantum HD y Serie FN Ink Xenon Hacer versiones populares de esta tinta.

Cinco razones principales para usar tinta plastisol de alta densidad

- Textura 3D:Hace diseños salir como una pegatina.

- Colores brillantes:Se mantiene vibrante camisas negras y telas oscuras.

- DurabilidadNo se agrieta, decolora ni pela después del lavado.

- Funciona en muchos materiales:Úselo en algodón, poliéster, bolsas, tazas y más.

- Rentable:Ahorra dinero porque las impresiones duran más.

Cómo utilizar tinta plastisol de alta densidad

Herramientas que necesitas:

- A pantalla con 110-160 mallas.

- A enjugador de goma (para empujar la tinta a través de la pantalla).

- A secador flash (para calentar y endurecer la tinta).

Guía paso a paso:

- Preparar la pantalla:

- Utilice una emulsión espesa.

- Mantenga la pantalla ligeramente por encima de la tela.

- Imprimir el diseño:

- Aplique la tinta 2 o 3 veces.

- Utilice el secador flash entre capas.

- Curar la tinta:

- Calor en 320°F para 45-60 segundos.

Consejo profesional:Máquinas como Equipos de impresión M&R dar los mejores resultados

Plastisol de alta densidad frente a otras tintas

| Tipo de tinta | Mejor para | Lo peor para |

|---|---|---|

| Plastisol de alta densidad | Texturas 3D, logotipos atrevidos | Proyectos ecológicos |

| Tinta al agua | Diseños suaves y ligeros | Telas oscuras |

| Tinta de descarga | Aspecto vintage y descolorido | Materiales de poliéster |

Ejemplo: Elegir plastisol de alta densidad para sombreros o camisas con logotipos en relieve.

Solución de problemas comunes

| Problema | Solución |

|---|---|

| Agrietamiento | Cura por más tiempo a 320°F |

| Sangrado de color | Agregar agentes de bajo sangrado |

| La tinta no se pega | Primero limpia la tela |

Herramienta para probar: Rutland EVO Los aditivos ayudan a prevenir el sangrado.

Tintas ecológicas de alta densidad

Las tintas más nuevas son más seguras para las personas y el planeta:

- Libre de ftalatos opciones (como MagnaColores).

- Seguir Estándar Oeko-Tex 100 (seguro para el contacto con la piel).

Consejo:Recicle pantallas y contenedores de tinta para reducir los residuos.

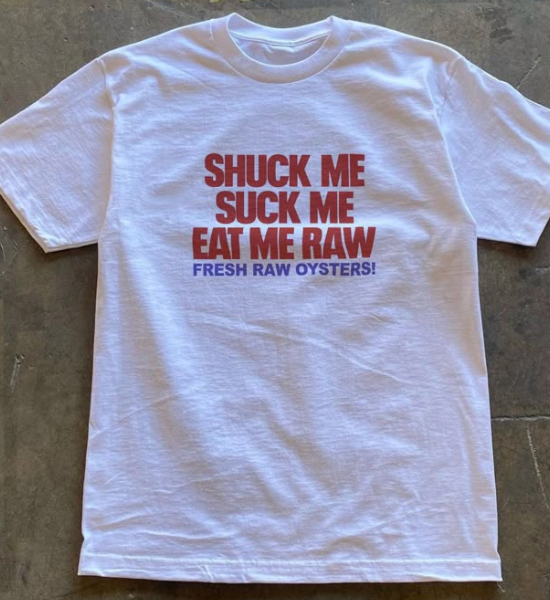

Ejemplos del mundo real

- Nike:Utiliza tinta 3D en camisetas deportivas para darle textura.

- Adidas:Fabrica camisetas de edición limitada con logotipos en relieve.

- Artistas:Crea arte de galería con diseños táctiles.

Evento:Ver nuevas tintas en IMPRESIÓN United Expo.

Tendencias futuras

- Tintas híbridas:Mezcle plastisol con tintas a base de agua para lograr suavidad y durabilidad.

- Herramientas digitales:Software como AccuRIP Ayuda a diseñar patrones precisos.

¿Deberías probar la tinta plastisol de alta densidad?

Si si quieres:

- Diseños que destacar.

- Impresiones que sobreviven más de 100 lavados.

Empieza poco a poco¡Pruébelo primero en una muestra de tela!

Preguntas frecuentes

¿Puedo usar esta tinta en poliéster?

¡Sí! Añade uno agente de bajo sangrado para evitar que los colores se propaguen.

¿Puedo imprimir detalles finos?

Utilice un Pantalla de más de 160 mallas Para líneas finas y textos pequeños.

¿Cómo reducir los residuos?

Mida la tinta con cuidado y reutilice las pantallas.