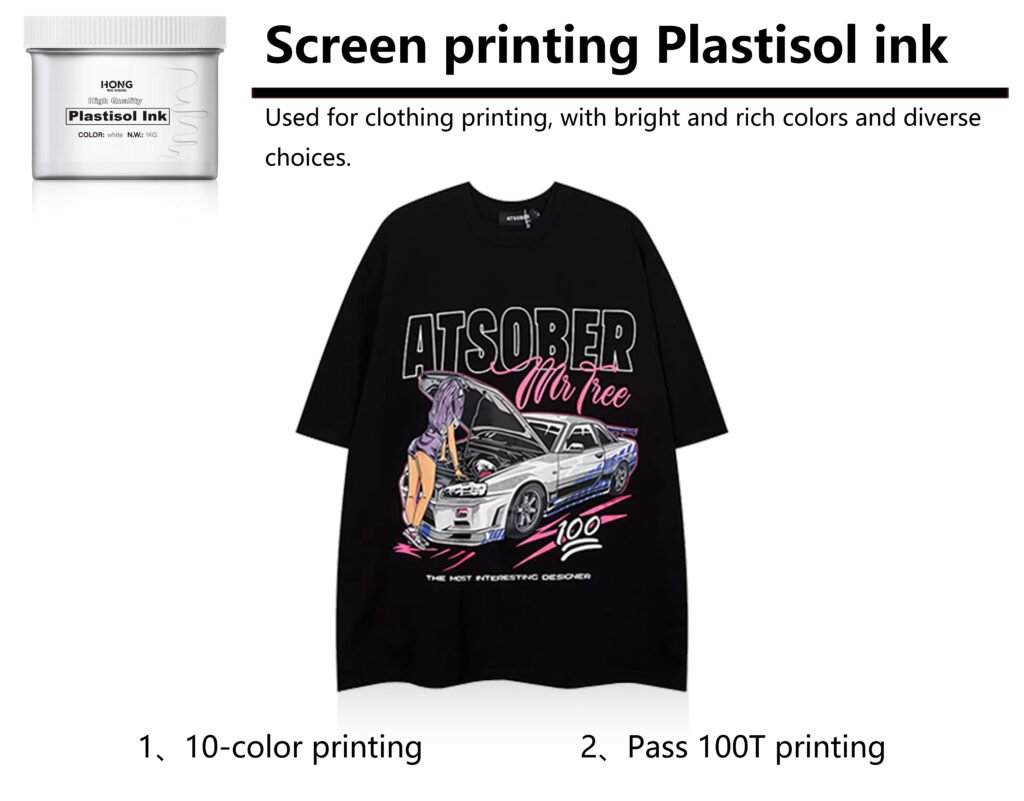

Fabricantes de tinta plastisol para serigrafía

El líder mundial fabricante de tinta plastisolNo importa cuál sea tu idea. Puedes conseguir la perfecta. solución de tinta para serigrafía de Hong Rui Sheng

Asociese con los mejores fabricantes de tinta plastisol

Tinta plastisol para serigrafía más vendida

Ecológico de nivel medio-alto, libre de ftalatos y NPEO, adecuado para marcas de nivel medio-alto.

Ecológico avanzado, apto para UE/EE. UU., sin ftalatos, sin formaldehído, sin PVC.

Ecológico normal, libre de metales pesados y ftalatos, adecuado para el mercado común.

ASOCIARSE CON LOS MEJORES FABRICANTES

Tinta de serigrafía de tela de alta calidad con colores vibrantes, fuerte cobertura, duradera y lavable, perfecta para diversas telas.

Tinta plastisol duradera y antideslizante para calcetines, colores vibrantes, suave y cómoda, adecuada para varios tejidos.

Tinta plastisol duradera y antideslizante para guantes, colores vibrantes, suave y cómoda, adecuada para varios materiales de guantes.

Servicios prestados por Hong Rui Sheng

Suministro de tinta plastisol de alta calidad

Soporte técnico y capacitación

Desarrollo de productos e innovación

Soporte de cadena de suministro y logística

Sobre nosotros

¿Quiénes somos?

Fabricante profesional de tintas plastisol para serigrafía en China

HONG RUI SHENG se ha consolidado como líder en la industria de tintas plastisol para serigrafía. Nuestra fábrica, ubicada en China, produce tintas plastisol de alta calidad con tecnología de vanguardia y rigurosos estándares de control de calidad. Además, nuestro equipo técnico innova continuamente para garantizar que nuestros productos se mantengan a la vanguardia del sector.

La misión de HONG RUI SHENG es ayudar a nuestros clientes a alcanzar sus objetivos comerciales proporcionándoles materiales de impresión de alta calidad. Nuestra visión es convertirnos en el socio predilecto de la industria global de la serigrafía, que reconoce no solo la calidad de nuestros productos, sino también la excelencia de nuestro servicio. Ya sea para producciones a gran escala o para necesidades personalizadas, HONG RUI SHENG puede brindarle las mejores soluciones.

¿Por qué elegir Hong Rui Sheng?

Líder mundial en tintas de plastisol diversas

Como proveedor profesional de tintas para serigrafía textil, Sollyd lidera la industria con una amplia gama de modelos de tintas para serigrafía y produce más de 100.000 toneladas diarias para garantizar un suministro constante. Nuestra presencia global abarca más de 1.000 colaboraciones a largo plazo en Europa, Norteamérica, Oriente Medio, Asia Oriental y otros países, lo que demuestra nuestro compromiso con los productos especializados.

La seguridad es nuestra máxima prioridad.

Los productos de Sollyd se someten a ocho rigurosas pruebas de seguridad, lo que garantiza una seguridad y calidad absolutas. Nuestra amplia cartera incluye más de 100 certificaciones, como OEKE-TEX, SGS, ISO9001, etc., lo que refuerza nuestro compromiso con la seguridad.

Equipo y equipamientos avanzados

Con un laboratorio dedicado a las pruebas de seguridad de tintas de plastisol, no hacemos concesiones. Nuestro ágil equipo incluye más de 30 expertos en I+D y más de 200 ingenieros de producto, siempre listos para ofrecer soluciones rápidas de tintas de plastisol.

¿Listo para serigrafiar? ¡Solicita tu presupuesto ahora!

¡Creemos que Hong rui sheng será su mejor socio!

Por favor, rellene el formulario con sus datos de contacto o llámenos y nos pondremos en contacto con usted en 24 horas.