Sisällysluettelo

Silkkipainomusteiden ymmärtäminen: tyypit, vinkit ja tekniikat

Silkkipainomusteet ovat hauskaa ja tärkeäNe tekevät taiteestamme kirkkaan ja vahvan. Tässä artikkelissa opimme silkkipainoväreistä. Puhumme tyypit, vinkkejä, ja tekniikatKäytämme taulukkoa ja luetteloita. Käytämme myös yksinkertaisia sanoja, jotta se on helppolukuinen kaikille[^1].

Mitä ovat silkkipainomusteet?

Silkkipainomusteet ovat Valitse ainutlaatuisia malleja varten erikoisvärejä painomusteessa.Ne menevät ensin näytölle ja sitten paidalle tai kyltille. Muste näyttää taiteemme, joten se näyttää... mukava ja viileäValitsemasi mustetyyppi voi muuttaa työsi ulkonäköä ja kestävyyttä. Se vaikuttaa myös siihen, kuinka helppoa tulostaminen on. Oikean musteen käyttö antaa sinulle kirkas värejä ja tekevät tulosteestasi kestävän pitkään.

Silkkipainomusteiden tyypit

Musteita on monenlaisia. Jokaisella on oma plussat ja haittojaTässä ovat päätyypit:

1. Plastisolimusteet

- Plussat:

- Vahva ja elinvoimainen värit.

- Helppo ensikertalaiset.

- Kestävä monilla kankailla.

- Miinukset:

- Ne tarvitsevat lämpöä kuivuakseen.

- Niissä on PVC:tä.

Paras:

- T-paidat ja läpinäkymättömät mallit.

- Monet kaupat käyttävät näitä musteita, koska ne ovat suosittu[^2].

2. Vesipohjaiset musteet

- Plussat:

- Lisää ympäristöystävällinen.

- He antavat a pehmeä Katso.

- Ne leviävät kankaaseen.

- Miinukset:

- Ne kuivuvat nopeasti.

- Ne vaativat enemmän taitoa.

Paras:

- Kestävää painatusta ja kevyitä kankaita.

- Maapallosta välittävät ihmiset rakastavat näitä musteita[^3].

3. Pura musteita

- Nämä musteet poistaa tummien kankaiden väri.

- He antavat a vuosikerta Katso.

- Paras:

- Vanhan koulun tunnelmaa omaavia puuvillakankaisia kuoseja.

4. Erikoismusteet

Tarjolla on monia hienoja erikoismusteita:

- UV-kovettuvat musteet:

- Kuivuu nopeasti UV-valossa.

- Ne käyttävät vähemmän energiaa.

- Puff-musteet:

- Saada pullea kun niitä lämmitetään.

- Ne antavat 3D-kosketuksen.

- Metalliset / pimeässä hohtavat musteet:

- Ne lisäävät vaatteiden painatukseen erityisen laadun. kimallus tai hehku tulosteisiin.

Nämä musteet voivat tehdä työstäsi erottua ainutlaatuisilla ulkonäöillä.

Kuinka valita oikea muste

On tärkeää valita oikea muste. Tässä on joitakin vinkkejä parhaan musteen valitsemiseen:

- Kankaan tyyppi:

- Puuvilla, polyesteri tai sekoitteet tarvitsevat erilaiset musteet.

- Viimeistely:

- Haluatko a kiiltävä katso, a matta katso, tai a kuvioitu loppuun?

- Ilmastonmuutos:

- Jos rakastat maapalloamme, etsi PVC-vapaita tai liuotteettomia musteita.

- Laitteet:

- Onko sinulla lämpöprässiä, kuivausrumpua tai UV-lamppua?

Silkkipainomusteen käyttövinkkejä

Saat upeita tulosteita noudattamalla näitä vinkkejä:

1. Pre-Pre-Preparation

- Puhdista näyttösi.

- Poista pöly ja vanha muste.

- Päällystä emulsiolla.

- Tämä auttaa sinua luomaan selkeän suunnittelun.

- Testitulostus.

- Tee pieni testi ennen kuin kirjoitat isoa tekstiä.

2. Musteen sekoitus ja yhtenäisyys

- Sekoita muste hyvin.

- Hyvä sekoitus antaa tasaisen musteen.

- Hallitse viskositeetti**

- Käytä tarvittaessa vaihteenrajoittimia tai hidastimia.

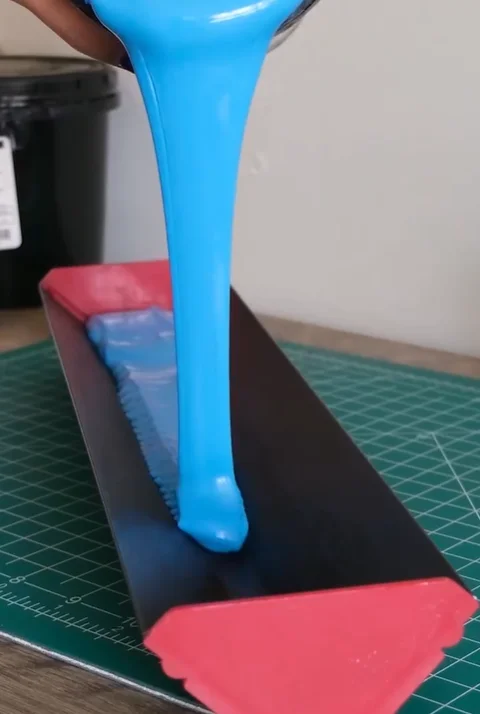

3. Vetolastan tekniikat

- Pidä lastaa hyvässä kulmassa.

- Käyttää oikea paine tasaista mustetta varten.

- Harjoitella vetolastan paine saadaksesi siistin tulosteen.

4. Kovetusmenetelmät

- Lämpöpaino:

- Erinomainen plastisolille.

- Kuljettimen kuivausrumpu:

- Kovettaa useita tulosteita nopeasti.

- Salamakovetus:

- Käytä lyhyitä lämpöpurskeita (pikakovetusta), kun tulostat ylimääräisiä värejä.

Nämä vaiheet auttavat mustetta tarttumaan hyvin ja kestämään pitkään.

Kehittyneet tekniikat parempiin tulosteisiin

Jotta tulosteesi näyttäisivät vielä paremmilta, kokeile näitä temppuja:

1. Monivärinen tulostus

- Käyttää rekisteröintimerkit joten jokainen väri sopii.

- Tee alapohja kerros.

- Käyttää pikakovetus kerrosten välissä.

2. Simuloitu prosessitulostus

- Käyttää puolisävyt tasaiseen värien häivytykseen.

- Tämä toimii fotorealistisissa malleissa.

3. Gradientti- ja sekoitustehosteet

- Yrittää märkää märälle painaminen.

- Käyttää halkaistu suihkulähde tekniikoita.

- Nämä aiheuttavat pehmeitä värinmuutoksia.

4. Verkkojen lukumäärä ja emulsiopinnoite

- Käytä sakkoa verkkojen määrä (230–305) terävien yksityiskohtien saamiseksi.

- Emulsiopinnoite Laatu on avain puhtaisiin tulosteisiin.

Yleiset silkkipainomusteen ongelmat ja korjaukset

Jopa aikuisilla voi olla tulostusongelmia. Tässä on joitakin yleisiä ongelmia ja helppoja korjauksia:

1. Musteen vuoto

- Ongelma: Muste ylittää reunansa.

- Aiheuttaa: Liian suuri tai liian alhainen paine verkkojen määrä.

- Korjata:

- Käytä suurempaa silmämäärää.

- Säädä vetolastan paine.

2. Huono tarttuvuus

- Ongelma: Muste ei tartu hyvin, varsinkaan läpinäkymättömillä musteilla.

- Aiheuttaa: Muste ei kovetu kunnolla.

- Korjata:

- Tarkista lämmönlähde ja aika.

- Varmista, että parantaa mustekaivo.

3. Näytön tukkeutuminen

- Ongelma: Mustetta kertyy näyttöön.

- Aiheuttaa: Kuivunut muste tukkii näytön.

- Korjata:

- Puhdista näyttö heti.

- Käytä näytönavaajaa.

4. Neulanreiät tai epäjohdonmukaisuudet

- Ongelma: Pieniä reikiä tai täpliä tulosteissa.

- Aiheuttaa: Pölyä tai ongelmia emulsiopinnoitteessasi.

- Korjata:

- Puhdista näyttö huolellisesti ennen käyttöä.

- Päällystä sihti uudelleen uudella emulsiomaalikalla.

Ympäristöystävälliset silkkipainokäytännöt

Monet tulostimet välittävät nykyään planeetastamme. Tässä ovat ympäristöystävällinen vinkkejä:

Vesipohjaiset vs. plastisolimusteet

- Vesipohjaiset musteet ovat vihreä.

- Niitä käyttävät nykyään 40%-tulostimet.

- Plastisolimusteet ovat vahvoja, mutta eivät yhtä vihreitä.

Kierrätys ja puhdistus

- Kierrätä käytetyt musteet.

- Käytä ympäristöystävällisiä puhdistusratkaisuja.

- Etsi musteita, jotka ovat PVC-vapaa.

Sertifikaatit

- Etsiä EU:n REACH-asetus ja vastaavat etiketit.

- Sertifioidut musteet auttavat sinua pysymään turvassa ja ympäristöystävällisenä.

Tiedot ja tilastot silkkipainomusteista

Alla oleva taulukko näyttää hyödyllistä dataa. Se auttaa meitä näkemään alan trendit ja keskeiset faktat.

| Luokka | Alla oleva taulukko näyttää hyödyllistä tietoa kangassilkkipainoväreistä. | Lähde | Relevanssi |

|---|---|---|---|

| Markkinatrendit | Markkinat kasvavat 4,81 TP4T:n vuosivauhdilla (2023–2030) | Grand View -tutkimus (2023) | Näyttää enemmän ihmisten painotaidetta. |

| Musteen käyttö | 65% markkinoista käyttää plastisolimusteita | Smithers Pira -raportti (2022) | Plastisoli on hyvin yleinen. |

| Kestävyys | 40%-tulostimista käyttää vesipohjaisia tai eko-liuotinmusteita | FESPA Global Print Expo (2023) | Yhä useammat ihmiset valitsevat vihreitä musteita. |

| Kovettumistehokkuus | UV-musteet vähentävät energiankulutusta 30%-tekniikalla | RadTechin UV-tutkimus (2021) | UV-musteet auttavat maapalloa. |

| Tapaustutkimus | ”EcoThreads” vähentää 50%:n tuottamaa jätettä luomupuuvillalle painetuilla purkausmusteilla | Kestävät brändit (2023) | Näyttää, miten purkausmusteet sopivat hyvin vihertöihin. |

| Yleisiä ongelmia | 25% vioista johtuu väärästä silmämäärästä | ScreenPrinting.com (2023) | Hyvä silmämäärä on erittäin tärkeä. |

| Kustannusanalyysi | Vesiohenteiset musteet maksavat 20% enemmän, mutta säästävät jätemaksuissa | Wilflex-musteen hinta (2023) | Vertaa kustannuksia pitkän aikavälin säästöihin. |

| Kestävyystilastot | Oikein kovettunut plastisol kestää yli 50 pesua; huono kovettuminen tekee 70%-tulosteista huonompia | Kansainvälinen pinnoitelaboratorio (2022) | Kovettuminen on avain pitkäkestoisiin tulosteisiin. |

| Tapaustutkimus | ”PrintPros” lisäsi 35%:n tuottoa älykkäiden musteensekoitusjärjestelmien avulla | Printwear-lehti (2023) | Tekniikka voi auttaa tulosteitasi. |

| Kuluttajien mieltymykset | 60% ostajista pitää vesipohjaisilla musteilla tehdyistä pehmeän käden vedoksista | SGIA:n kuluttajakysely (2023) | Käytä vesiohenteisia musteita pehmeän tuntuman saavuttamiseksi. |

| Laitteiden vaikutus | 230–305 mesh-luku auttaa siistissä simuloidussa prosessitulostuksessa | Ryonetin tekninen opas (2023) | Silmätiheydellä on merkitystä kuvataiteessa. |

| Sääntelytiedot | PVC-vapaat musteet täyttävät EU:n REACH-standardit | EU:n kemikaaliasetustietokanta | Noudata sääntöjä ja pysy turvassa. |

| Tapaustutkimus | Kiwon hybridimusteet vähentävät seulan tukkeutumista 90%:n avulla suurissa tulostusmäärissä | Kiwon menestystarina (2023) | Hybridimusteet sopivat hyvin suuriin tilauksiin. |

| Pestävyys | Purkausmusteet säilyttävät 95%-värin 30 pesun jälkeen puuvillakankaalla | Jacquard-testaus (2022) | Hyvä kestävään väriin. |

| Koulutuksen vaikutus | Koulutetut tulostimet saavat 50%:llä vähemmän musteenkulutukseen liittyviä virheitä | TULOSTUS Yhdistynyt liitto (2023) | Koulutus on erittäin hyödyllistä. |

| Niche-sovellukset | Johtavia musteita käytetään puettavien teknisten laitteiden 15%-versioissa. | IDTechEx-raportti (2023) | Käytä teknisiin tulosteisiin erikoismusteita. |

| Ympäristösertifikaatit | SGP-sertifioidut tulostimet säästävät $5k vuodessa vähemmällä jätteellä ja energialla | SGP-tapaustutkimus (2023) | Sertifikaatit säästävät rahaa ja resursseja. |

Käytännön vaiheita parhaiden tulosten saamiseksi

Tässä on selkeät ja yksinkertaiset vaiheet, joita voit noudattaa hienoa painaa:

- Valmistele työsi

- Puhdista näytöt.

- Käytä tuoretta emulsiota selkeän suunnittelun saavuttamiseksi.

- Sekoita musteesi

- Sekoita hyvin, kunnes muste on tasaista.

- Älä anna musteen kuivua.

- Tulosta hyvällä lastalla

- Pidä lattianpyyhintä kulmassa.

- Paina oikealla vetolastan paine.

- Käytä tasaisia vetoja saadaksesi siistin lopputuloksen.

- Koveta musteesi

- Käytä lämpöprässiä tai kuivausrumpua.

- Tarkista jokaisen vedoksen kovettumisajat varmistaaksesi värien peittävyyden.

- Tarkista ja korjaa ongelmat

- Etsi mustevuoteluja tai reikiä.

- Korjaa silmämäärä tai puhdista näytöt.

Näiden vaiheiden avulla voit tehdä tulosteita, jotka ovat pitkäkestoinen ja kirkas.

Vinkkejä erikoismusteiden käyttöön

Erikoismusteet voivat tehdä taiteestasi ainutlaatuista. Tässä on muutamia yksinkertaisia vinkkejä:

- UV-kovettuvat musteet:

- Käytä UV-valoa musteen nopeaan kovettamiseen.

- Ne säästävät energiaa käyttämällä 30% vähemmän virtaa[^2].

- Puff-musteet:

- Ne turpoavat, kun niitä lämmittää.

- Ne luovat hauskan, 3D-ilmeen.

- Metalliset ja pimeässä hohtavat musteet:

- Käytä näitä musteita erikoistehosteisiin.

- Ne lisäävät suunnitteluusi kimallusta tai hohtoa.

Kun käytät näitä musteita, noudata samoja vaiheita: sekoita, tulosta ja koveta.

Tarkastele edistyneitä tekniikoita yksityiskohtaisesti

Edistyneet tekniikat voivat viedä tulosteesi pois hyvä kohtaan hämmästyttäväKatsotaanpa tarkemmin.

Monivärinen tulostus

- Suunnittele etukäteen:

- Tee suunnitelma jokaisen värin kanssa.

- Käytä rekisteröintimerkkejä:

- Nämä merkit auttavat värejä asettumaan kohdalleen.

- Pohjakerros:

- Tulosta ensin vaalea väri ja lisää sitten muut värit.

- Salamakovetus:

- Koveta kerrosten välillä estääksesi musteen liikkumisen[^2].

Simuloitu prosessitulostus

- Rasterointisekoitus:

- Käytä pieniä pisteitä värien sekoittamiseen.

- Vaiheittainen opas:

- Tulosta kerrokset hitaasti.

- Katso värien sekoittumista.

Gradientti- ja sekoitustehosteet

- Märkää märälle -tekniikka:

- Tulosta värit märälle musteelle tasaisen sekoittumisen aikaansaamiseksi.

- Jaetun suihkulähteen tekniikka:

- Käytä yhtä lastaa ja kahta väriä.

Näillä tekniikoilla voit saada tulosteesi näyttämään aidolta taiteelta.

Oppiminen ja koulutus

Asiantuntijoilta oppiminen auttaa. Harjoittelu voi vähentää virheitäsi 50%[^2]. Tässä on tapoja parantaa suoriutumista:

- Verkko-opetusohjelmat:

- Etsi videoita ja yksinkertaisia oppaita.

- Työpajat:

- Liity lähelläsi olevalle kurssille.

- Harjoitella:

- Mitä enemmän tulostat, sitä paremmaksi tulet.

Yritä oppia lisää verkkojen määrä ja emulsiopinnoiteKokeile erilaisia lastatekniikatJokainen harjoitus tekee sinusta paremman painajan, etenkin Speedball-kangasmusteita käytettäessä.

Usein kysytyt kysymykset silkkipainomusteista

Alla on joitakin yleisiä kysymyksiä ja vastauksia:

Voinko sekoittaa plastisoli- ja vesipohjaisia musteita keskenään?

Ei, niiden sekoittaminen voi aiheuttaa ongelmia tulostuksessa.

Kuinka monta pesukertaa tulosteet kestävät?

Hyvin kovettunut plastisol kestää yli 50 pesua. Mutta jos sitä ei koveteta, painatus voi irrota.

Mikä on paras muste joustaville kankaille?

Vesiohenteiset musteet sopivat parhaiten pehmeille ja joustaville kankaille.

Säästävätkö UV-kovettuvat musteet energiaa?

Kyllä, ne käyttävät 30%:tä vähemmän energiaa.

Mikä muste sopii parhaiten vihreään projektiin?

Vesiohenteiset, purkaus- tai erikoisekomusteet ovat hyviä valintoja.

Yhteenveto: Tärkeimmät muistettavat asiat

- Silkkipainomusteet tee taiteestamme kirkasta.

- Niitä on monia tyypitPlastisoli, vesipohjainen, purkaus- ja erikoismaalit.

- The oikea muste riippuu kankaasta, viimeistelystä ja ympäristöystävällisistä tarpeista.

- Käytä hyvää lastatekniikat ja verkkojen määrä täydellisiä tulosteita varten.

- Harjoittele ja koulutus auttaa sinua käyttämään mustetta hyvin.

- Käyttää ympäristöystävällinen musteita kirkkaampaan ja vihreämpään tulevaisuuteen.

Työpöytä pikaohjeita varten

Tässä on nopea hakutaulukko, joka auttaa sinua muistamaan tärkeät tiedot:

| Tyyppi / tekijä | Avainkohta | Kärki |

|---|---|---|

| Plastisol-muste | Yleinen ja elinvoimainenTarvitsee lämpökovetuksen. | Käytä T-paitoihin ja näyttävään taiteeseen. |

| Vesipohjainen muste | Ympäristöystävällinen ja pehmeä. Kuivuu nopeasti. | Paras vaaleille kankaille, vihreälle työlle. |

| Pura muste | Poistaa värin vintage-ilmeen saamiseksi. | Loistava puuvillalle vanhan koulun tyylillä. |

| Erikoismuste | UV-kovettuva, pöyhivä, metallinen, hohtava. Käytä tarpeen mukaan. | Lisää tulosteisiin erikoistehosteita. |

| Silmien lukumäärä | 230–305 lisätietoja. | Käytä ohuita tulosteita varten hienojakoista verkkoa. |

| Puristimen paine | Tasapainoinen työntö antaa tasaisen musteen. | Harjoittele siistiä lopputulosta varten. |

| Flash-kovettuva | Nopeat lämmönpurkaukset lisäkerroksia varten. | Käytä monivärisiin tulosteisiin. |

| Emulsiopinnoite | Pitää yksityiskohdat terävinä. | Puhdas sihti auttaa emulsiota tarttumaan. |

Päätelmä

Silkkipainomusteet ovat sydän upeita tulosteita. Monien lajit mustetta, voit valita itsellesi parhaiten sopivan. Näitä yksinkertaisia vinkkejä noudattamalla voit luoda taidetta, joka on kirkas, pitkäkestoinen, ja kaunisMuista käyttää hyviä verkkojen määrä, oikea vetolastan paineja tee pikakovetus oikeisiin aikoihin. Harjoittele, opi ja kokeile uusia työkaluja, kuten Wilflex, Speedball, ja Jakardi musteet. Nämä vaiheet auttavat sinua tekemään jokaisesta tulosteestasi parhaan mahdollisen.

Jokainen vaihe esipainatuksesta kovetukseen lisää erityinen kosketus työhösi. Käytä ympäristöystävällisiä musteita maapallomme suojelemiseksi. Anna tulosteidesi loistaa väriä ja elämää. Jos noudatat vinkkejämme ja tarkistat faktat, kuten markkinatrendi ja yleisiä ongelmia, tulosteesi paranevat päivä päivältä.

Pysy uteliaana ja jatka oppimista. On monia tapoja tehdä silkkipainotaidosta entistä hauskempaa. Hyödynnä koulutusta, kokeile edistyneet tekniikatja lue aiheesta erikoismusteet laajentaaksesi taitojasi. Ajan ja huolen avulla teet vedoksia, joista monet pitävät.

Kiitos lukemisesta. Toivomme, että tiedät nyt enemmän aiheesta. silkkipainomusteetTee oma taide eloisa ja kestäväOnnea tulostamiseen!