Key Points: Tips for a stunning white display printing effect

- Choose the proper ink: Choose a excessive transparency, low bleed ink, specially for polyester fabrics and blends.

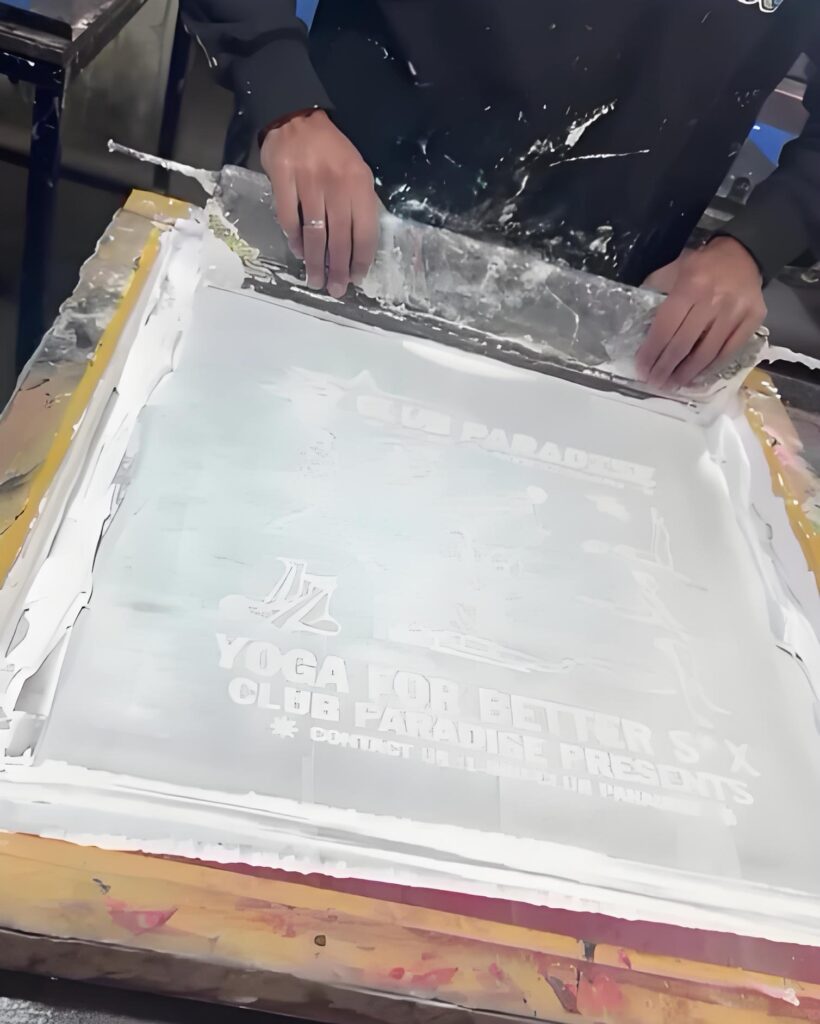

- Adjust the printing parameters: If you want to offer a wealthy and alluring white shade, use a lower mesh display screen to make the ink deposit thicker.

- Use the glitter method skillfully: Adopt the “print – sprinkle glitter – reprint” (print-glitter-print) approach to create an excellent white colour by way of printing in layers and avoid over-curing.

- Cure with care: Pay attention to curing temperatures and live instances, and always perform a wash test to make certain print durability.

- Optimize the printing procedure: preheat substrate trays and maintain squeegees easy for satisfactory effects.

- Brand desire is important: attempt distinctive manufacturers of white plastisol inks, consisting of Wilflex and International Coatings, to discover the fine option.

- Adjust as needed: Add additives or exchange ink viscosity as had to make certain smooth, even printing.

- Stay affected person: Mastering details calls for trial and errors and keen interest to element.

- Keep it smooth: Avoid emulsion buildup by means of preserving the screen and adjusting it to the cloth or substrate.

- Focus on protection: Choose phthalate-unfastened inks for a safer printing surroundings.

- By following these fine practices, you may be capable of deliver crisp, vibrant white prints on any fabric that customers will rave approximately whenever!

Peut-on utiliser de l’encre blanche à base d’eau avec de l’encre plastisol ?

Résumé :

If you’ve ever struggled with getting that best white on a display screen published shirt, you’re not by myself. White ink—particularly white plastisol ink—can be one of the trickiest yet most essential gear inside the display printer’s toolkit. Whether you’re a professional printer aiming for the maximum opaque, low bleed prints, or you’re simply curious why your white display prints look stupid or patchy, this complete manual is for you. We’ll damage down the technology at the back of ink, explore the pleasant strategies for printing white ink, talk curing, and share professional hints for a lasting, vibrant white print. You’ll go away with the know-how needed to pick the high-quality white plastisol ink, keep away from not unusual pitfalls like dye migration and bleed, and grasp your display screen printing sport. Let’s dive in!

Plan de l'article

- What Makes Ink So Important in Screen Printing?

- Why Use White Plastisol Ink for Screen Printing?

- What Are the Key Features of White Ink for Print Quality?

- How Does Printing with White Ink Differ from Other Inks?

- What Are the Top Tips for Perfecting Your Screen Print with White?

- How Do You Properly Cure White Plastisol Ink?

- What Is the Best White Plastisol Ink—and What Sets It Apart?

- Choosing the Right Printer and Pallet Setup for White Ink

- What Are the Most Common Types of Ink for Screen Printing?

- FAQ: Achieving a Brilliant White Print Every Time

1.What Makes Ink So Important in Screen Printing?

Ink isn’t just coloration—it’s the heart and soul of every screen print. The first-class of your ink determines the whole thing from print first-class to the gentle hand experience of the completed garment. When you pick the proper ink for display screen printing, you ensure that your designs look colourful, face up to a couple of washes, and achieve best insurance on any substrate.

But no longer all ink is created same. Factors like opacity, viscosity, and bleed resistance come into play, particularly while managing tough substrates like polyester or mixed fabric. For example, using an opaque white ink can help combat dye migration and bleed, keeping your white print crisp and clean.

Ultimately, the right ink preference affects production efficiency, customer pride, and the durability of your prints. That’s why know-how ink is crucial for every display screen printer, whether you’re the usage of manual techniques or complete automation.

2.Why Use White Plastisol Ink for Screen Printing?

Encre plastisol blanche is the enterprise preferred for printing white on darkish garments and as an underbase layer. Its specific opaque properties imply that a single ink deposit can acquire advanced brightness, overlaying even the darkest fibers with fewer strokes.

Because white plastisol ink sits on pinnacle of the material as opposed to soaking in, it creates a bold, lengthy-lasting print. It’s also clean to work with—plastisol inks have a thicker consistency, which permits for clean to print coverage, specifically whilst the usage of a lower mesh display screen like one hundred ten mesh for one stroke software.

When you pick out white plastisol ink, you’re setting yourself up for constant results and robust print sturdiness. It’s ideal for cotton clothes and can be changed with additives or adjusted viscosity for unique applications.

3.What Are the Key Features of White Ink for Print Quality?

For extremely good printing white ink, search for ink formulas that promise excessive opacity and coffee bleed. An opaque white or low bleed ink facilitates save you dye migration from polyester fabric, making sure that your whites stay natural and don’t flip purple or gray over the years.

The proper white ink affords a nice matte finish, dries constantly, and holds up properly to a wash check. Modern inks designed for display screen printing are regularly non-phthalate, making them safer for both your group and the environment.

Remember, nice white ink should provide brilliant print pleasant even on hard substrates, whether or not you’re printing an beneath-base or laying down a white print as the very last color. Always test the opacity and resistance to bleed to guarantee striking whites in each venture.

4.How Does Printing with White Ink Differ from Other Inks?

Printing with white ink is a completely unique mission. Unlike different colorations, white ink wishes to be extremely opaque to cover the fiber of both cotton garments and particularly polyester or combo substances. Using a thicker ink is common—this may call for tweaks to your mesh remember, squeegee durometer, or even your printing stroke technique (push or pull).

Additionally, printing white ink requires a eager eye for flash drying, as you can need to apply the print-flash-print technique: you print one layer of white ink, flash it to gel (however not fully treatment), then print some other layer on top for added vibrancy and coverage.

Because white ink sits extra visibly at the material, your alternatives in emulsion, mesh, and even preheat or pallet temp can all play key roles in generating an ideal white result. Small modifications in manner can cause massive adjustments inside the look and longevity of your prints.

5.What Are the Top Tips for Perfecting Your Screen Print with White?

First, continually take a look at your mesh be counted. A decrease mesh like 110 mesh lets in for a extra ink deposit, perfect for a bold, opaque white print on darkish garments46. Pair this with a medium or smooth durometer squeegee, which allows lay down a smooth, even layer of ink with minimum effort.

Second, screen your pallet temp and use a short flash between layers. Flash curing guarantees your white ink gels however doesn’t absolutely treatment, so the layers adhere with out graininess or fuzziness5. If dye migration or bleed is a challenge—in particular on polyester or combo clothes—opt for a low bleed or forte polyester inks designed to combat this issue.

Finally, don’t overlook protection. Clean your monitors cautiously to prevent emulsion buildup and constantly run a wash test before committing to large runs. If needed, adjust your ink mixing with accredited additives or reducers to excellent-track viscosity and print pleasant.

6.How Do You Properly Cure White Plastisol Ink?

Durcissement encre plastisol blanche successfully is essential for sturdiness and wash-fastness. The most commonplace cure temp for plastisol is round 320°F (a hundred and sixty°C), though a few low treatment formulations can therapy at decrease temperatures, best for delicate substrates or decreasing hazard of bleed on poly fabric.

To cure consistently, use a super dryer—both a conveyor dryer for automation or a effective flash remedy unit for small runs. Allow for an extended reside time if the ink layer is especially thick; inadequate curing can cause cracks, fading, or failed wash assessments.

When the usage of a dryer, keep away from overheating that may reason gelation in place of complete cure, or sizzling on polyester fabrics. Always test the therapy white by way of stretching the print and appearing a wash test—the pleasant white prints preserve opacity and softness even after repeated washes.

7.What Is the Best White Plastisol Ink—and What Sets It Apart?

Choosing the great encre plastisol blanche depends in your desires, but a standout choice is an opaque white with low bleed homes. Look for brands hailed by way of printers for his or her excessive opacity, clean finish, and resistance to dye migration, along with Wilflex or International Coatings. These ink brands paintings exquisite on both cotton clothes and tricky polyester blends.

Top-tier white plastisol ink offers an clean to print revel in, boasts a pleasing matte end, and continues your production lines jogging easily—even at excessive speeds or with automation. Ensuring the ink works for both manual and automated presses, and offers alternatives for different mesh screens, is prime for any printer desiring versatility and scalability.

Experiment and examine extraordinary brands by means of strolling wash checks, checking print satisfactory, and considering how the ink holds up through dye migration and bleed. Don’t forget to look for non-phthalate alternatives if eco-friendliness is essential to your business.

8.Choosing the Right Printer and Pallet Setup for White Ink

Achieving stellar white prints calls for more than simply first-rate ink—your desire of printer and pallet setup could make or spoil your method. Ensure your platen is well aligned and preheated earlier than printing, as cold platens can reason uneven ink transfer and extend flash times, impacting cure5.

If you’re the usage of a guide press, awareness on constant push or pull techniques and optimize your squeegee durometer for extended manipulate. For large runs, automation and conveyor dryers provide you with repeatable results and quicker production, specifically vital for plastisol display printing shops34.

A pleasant pallet with a terrific tack (however not too sticky) ensures your blouse remains positioned throughout printing, while a properly set print-flash-print series helps stack up those best whites without ghosting or registration issues.

9.What Are the Most Common Types of Ink for Screen Printing?

There are several forms of ink famous in display screen printing, every imparting particular results. Plastisol inks reign excellent for his or her versatility, excessive opacity, and forgiving remedy home windows. These inks are best for formidable, solid prints and paintings specially well for printing white ink on dark fabric.

Water-based inks provide a gentle hand sense and are an eco-friendly opportunity, however they lack the opacity of plastisol—making them less suitable for white print programs until used as an underbase. You’ll additionally discover forte polyester inks, formulated for optimum low bleed and dye migration resistance on poly substrates.

Always mix your ink nicely and keep in mind of additives or reducers to strike the proper viscosity to your job. Color matching using Pantone courses or custom colors is likewise important for projects requiring specific logo shades.

10.FAQ: Achieving a Brilliant White Print Every Time

Q: Why does my white ink look stupid on darkish shirts?

A: You is probably using an ink with low opacity, or making use of too little ink deposit. Try a lower mesh display and red meat up your stroke count or use print-flash-print.

Q: How do I save you bleed or dye migration on polyester?

A: Use a low bleed or area of expertise polyester ink designed for high-temp packages. Keep your therapy temp as low because the ink system lets in, and always preheat the pallet.

Q: How do I take a look at if my ink is cured properly?

A: Do a wash take a look at: print a take a look at shirt, remedy it, then wash and dry several instances. If your white print cracks or fades, boom your dryer dwell time or take a look at your cure temperature.