Curious approximately what makes every screen print vibrant and long-lasting? Whether you’re a print store seasoned or a newcomer to shirt printing, knowledge ink, display printing ink, paint, and plastisol makes all of the distinction. This in-depth manual unpacks kinds of ink, a way to select the excellent screen printing ink in your undertaking, seasoned recommendations on accomplishing long lasting, wonderful prints, and should-realize safety (OSHA!) pointers. Get equipped to dive deep into the sector of display screen print technology, find out the ideal ink to your shirt or garment, and spot why manufacturers like Jacquard and International Coatings set industry requirements. With sensible advice and real-existence insights, you’ll learn how to make every print pop!

תוֹכֶן הָעִניָנִים

1. What Is Screen Printing Paint? Exploring the Basics of Print, Ink, and Paint

Screen print, frequently known as silk screening, is a flexible print approach that pushes ink through a mesh display to transfer designs onto fabric, paper, wood, or different surfaces. Unlike virtual print, it creates bright, long lasting snap shots with incredible opacity, making it a top desire for t-blouse and garment printing. The coronary heart of any vibrant screen print lies in outstanding display printing ink, cautious selection of paint, and the right combination of adhesive and pigment to make sure lasting vibrancy.

Understanding the center standards—which includes the position of screen ink, the difference among ink and paint, and the way pigment and binder work together—units the muse for selecting the right products and attaining professional effects. Paint in display screen printing is normally formulated otherwise than wall or canvas paint; it is a specialized paste or liquid, engineered for max adhesion, brilliant shade, and compatibility with numerous textiles like cotton, polyester, rayon, and synthetic blends.

When you draw close these fundamentals, you streamline the complete procedure, from mixing colours and deciding on a squeegee to reclaiming your display screen for the next large task. Proudly showing every print becomes a testomony for your determination to exceptional and craft.

2.How Does Ink Work in Screen Printing?

Screen printing ink isn’t your everyday ink. It have to be formulated to skip via the mesh, persist with a fabric or floor, and live on repeated washing, exposure, and put on. These specialized inks—whether or not plastisol, water-primarily based, or discharge—characteristic pigment for colour, adhesive components, and from time to time extenders or components like puff, solvent, or varnish to tweak performance.

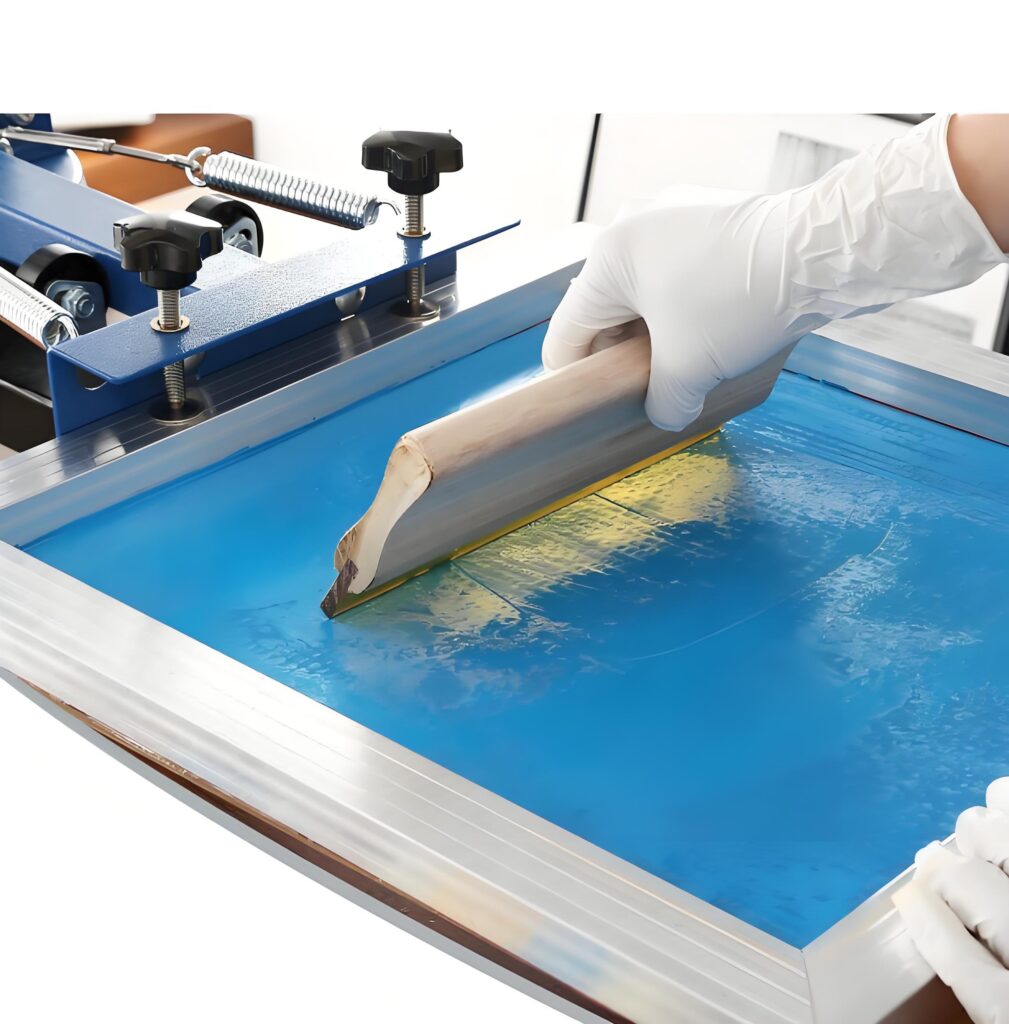

The system starts with preparing the display, coating it with emulsion, drying, and exposing your design. Once geared up, you position your cloth—like a shirt—on the press, add ink, and use a squeegee to transfer the photo. What units display screen printing ink apart is its open time; it stays plausible longer, giving display printers a hazard to print complex, multi-coloration artwork with out clogging the mesh or drying too quickly.

During curing, the ink bonds firmly to the cloth fibers. This step is essential—particularly for plastisol ink—which need to reach right warmth (regularly known as the “remedy” temperature) for most effective sturdiness and cloth adhesion. This is why using the ideal drying system or warmness placing is critical for lasting colourful prints.

3.Choosing the Right דיו להדפסת מסך: Plastisol, Water-Based, or Discharge?

Selecting the first-rate screen printing ink depends for your venture’s desires, the material, and your chosen print fashion. Plastisol ink, the enterprise widespread, is a PVC-primarily based display ink famend for its opaque finish, ease of use, and awesome opacity—best for colourful designs, darkish shirts, or prints that require smooth pop.

Water-primarily based inks offer a softer, eco-friendly sense and can penetrate fabric fibers, developing a more “in-the-cloth” look that’s popular for fashion garb. These inks dry in a different way than plastisol and might require components like an extender for artificial fabrics or open time manipulate. Discharge inks chemically bleach the blouse’s dye and replace it with pigment, resulting in superb-gentle, vintage-style prints which are still remarkably vibrant.

Acrylic display screen printing inks and jacquard display printing inks are options for artists wanting versatility, strong point finishes, or textile printing on nylon, vinyl, or synthetic fabric. Some brands provide more than a few series inks tailor-made for unique surfaces or results, making your choice of screen printing substances bendy and creative.

4.What Makes Plastisol Ink the Pro’s Choice?

Plastisol ink sits at the top of the screen print international for correct reasons: advanced opacity, colourful shades, and unbeatable sturdiness. Unlike paint or water-primarily based inks, plastisol doesn’t air dry—it handiest treatment plans when heated, ensuring lengthy-lasting, washer-friendly prints best for every print save or pro printer.

With its PVC and plasticizer combination, plastisol promises amazing print on each cotton and polyester, and stands up to repeated washings whilst keeping its shade and gloss. Brands innovate with non-phthalate, low-treatment, and even eco-friendly formulations to fulfill OSHA and environmental guidelines without compromising fine. Additives like puff, reflective, or extender can create lots of display screen printing effects, from 3-D textures to particular overprint finishes.

Another seasoned advantage? Plastisol’s forgiving nature. You can reclaim monitors effortlessly, and its bendy paintings time we could print stores deal with huge runs with out clogging or rapid drying. No surprise brands like Rutland and International Coatings have emerge as enterprise benchmarks for wonderful, flexible inks

Printing on shirts and different garments demands both art and technology. The form of screen printing ink, the kind of press, the squeegee used, and the way you deal with the garment all issue into developing a ideal, durable result. For smooth fabrics like cotton or blends, each plastisol and water-primarily based inks can supply easy, smooth prints with sharp edges and vibrant colors.

5. Screen Printing on Shirts and Garments: What to Know

For polyester, nylon, and other artificial fibers, you could need area of expertise inks or components—otherwise, you risk dye migration, bad adhesion, or prints that wash out in advance. Selecting the right adhesive and warmth placing at some point of curing helps the ink bond completely with the textile, ensuring every print appears professional and lasts long.

Focus on proper blouse prep: pre-treating, using lint rollers, and checking alignment before every print will pay off. Attention to these steps distinguishes pro shops from amateurs—and guarantees your prints rise up to years of wear and laundering

6.How Do Print Shops Ensure Durability, Adhesive Strength, and Every Print Lasts?

Ensuring the durability and vibrancy of every print method following pleasant practices at each step. Print stores display remedy temperatures intently; plastisol ink typically requires 320–330°F (one hundred sixty–165°C) to fully cure, fusing the pigment with the cloth fibers for a washable, lengthy-lasting result.

Choosing inks and paint with top notch opacity and sturdy adhesive houses manner your designs live crisp—even after dozens of washes. For uniqueness desires, some professionals use overprint varnish, puff components, or reflective inks to feature each durability and unique visual attraction.

Routine wash-exams, the use of top notch substances from depended on suppliers, and keeping the proper open time with extenders preserve print shops on pinnacle in their sport. The outcome? High-satisfactory, durable results that hold clients coming back for extra colourful prints.

7. Innovations in Ink: Eco-Friendly and Non-Phthalate Formulations

Modern screen print era is greener than ever. With rising demand for environmentally friendly and eco-friendly screen printing ink, manufacturers are rolling out water-based totally inks, non-phthalate plastisol, and PVC-free alternatives. These now not handiest reduce environmental effect however additionally follow tightening OSHA and global protection standards.

Non-phthalate plastisol inks, as an example, provide the identical brilliant coloration and remedy reliability with out the health dangers associated with older PVC/plasticizer blends. Eco-pleasant water-based totally inks are best for fashion prints, gentle shirts, and artificial cloth where softness and breathability are priorities. They additionally streamline easy-up, as they’re water soluble and don’t require harsh chemical substances for reclaim.

Stay ahead with the aid of selecting ink and paint that meets both purchaser expectations and environmental obligations—future-proofing your print store and showcasing your pro credentials

8. Why Ink Matters: Achieving Vibrant, Durable Prints on Shirts and Apparel

Simply placed: the ink you select determines the look, feel, and longevity of your print. High-satisfactory screen printing ink creates vibrant prints with amazing opacity, that’s specifically vital for brands targeted on making their artwork pop on each light and dark textiles. Choosing the right ink guarantees every print is as durable as it’s miles beautiful, from shirts and sweatshirts to banners and bags.

Durability is a top challenge for pro print stores. The cured ink must withstand dozens of washes without cracking, fading, or peeling. Plastisol shines here with its capability to bond with both herbal and artificial fabrics like rayon, nylon, and polyester. Water-based inks, while well heat set, additionally offer remarkable longevity and hand-sense, but require more care within the curing process to ensure results.

Don’t overlook approximately area of expertise inks and components that allow screen printers to stretch design limitations—puff additive for three-D seems, reflective pigment for particular branding, or maybe stretch additives for athletic put on. By expertise your selection of display printing inks, you can formulate prints that wow clients in any market.

9. Essential Tools: Screen Printing Press, Squeegee, and Adhesive

A top-notch display screen printing press is the printer’s spine. Whether manual or automated, your press guarantees specific placement, even stress, and consistent outcomes on every print. For the house DIY-er, a simple tabletop press may suffice; for industrial print shops, multi-colour rotary presses streamline manufacturing and improve efficiency for huge orders.

Don’t overlook the humble squeegee—a critical tool for forcing ink via the display mesh and onto your selected substrate. The hardness (durometer) of your squeegee, blended with approach, impacts the very last print’s readability, coverage, and sharpness. Using the right adhesive (spray or platen glue) is equally essential. This continues your garment or cloth in place at some stage in the printing system, making sure each print traces up perfectly, particularly at some point of multi-coloration jobs and transfers.

Other have to-have display printing substances include reclaim gear (for cleansing screens), emulsion, exposure devices, and curing device. Together, these turn your innovative vision right into a tangible, fantastic product—whether it’s the hundredth print for a logo or the very first blouse you design for a laugh!

10. All About Plastisol and דיו פלסטיזול: The Pro’s Favorite

Plastisol is a polymer-based totally ink that revolutionized business screen printing on fabric and clothing, thanks to its versatility and forgiving nature. Plastisol ink stays liquid till exposed to enough warmness—“cure” temperatures generally range from 320°F to 340°F, relying on the brand and variety. This approach you can take a while while lining up specified prints or multicolor jobs without the ink drying up in the screen.

What makes plastisol ink this type of seasoned preferred? It gives tremendous opacity, even on darkish garments, and bonds to almost any fiber, from cotton to polyester and blended textiles. Recent advances—like low cure and non-phthalate formulation—make it less complicated than ever to gain gentle, durable, eco-friendly prints with bright gloss and clean hand sense. Additives like puff or stretch effect texture or stretch, letting screen printers get even extra creative with their lineup.

Cleanup and reclaim also are streamlined: plastisol doesn’t air dry, so un-used ink in your display can be scraped off and saved for later. This reduces waste (and cost), making plastisol best for print shops strolling plenty of jobs, transfers, or overprints on shirts and synthetic fabric.