Curious how metallics and area of expertise screen printing ink revolutionize the world of print and layout? This article is your complete guide to know-how how ink, print approaches, and substances like metallic come together to create expert-grade, steel effects. If you want your product to face out with colourful, durable, super finishes—particularly on surfaces like lined metals, plastics, and more—this guide is made for you. By studying on, you’ll discover the technological advances, smart picks, and professional suggestions that carry your print project to lifestyles in the most wonderful approaches.

Table of Contents

1. What is Metallic Ink and Why Is It So Popular in Print Today?

Metallic ink is a uniqueness ink containing best metallic debris like aluminum or stainless-steel that deliver a unique, reflective impact to any revealed floor. The ensuing metal print gives a dynamic “pop” and pricey gloss that preferred ink or maybe opaque colors sincerely can’t in shape. That rich shimmer is an on the spot head-turner, making it a favorite preference for product packaging, invites, labels, and high-impact branding substances.

One large motive metal ink is seen in the whole thing from mag covers to client items? Its versatility. Printers and architects use it to present their projects an excessive, expert area, whether or not they’re creating captivating commercial enterprise cards or including aptitude to shop signage. The sort of metal sun shades available has additionally grown, with the whole lot from traditional gold and silver to particular color mixes now an option on your next print undertaking.

2.How Does Metal Screen Printing Ink Differ from Traditional Ink in Printing?

Traditional ink is usually pigment-primarily based with out metal particles, ensuing in a flatter, much less reflective finish. In assessment, metal ink makes use of a base of both water-based totally or solvent formulas, infused with actual metallic flakes. This gives not just that signature shine, however additionally a distinctive consistency—frequently a easy, thick paste best for display printing.

Another key distinction? Coverage and opacity. Metallic ink is in particular formulated to offer terrific insurance even on dark or covered metals, plastics, or paper. Unlike many standard inks, metallics stand out fantastically on a clean or coloured substrate, retaining their rich shade and reflective gloss after a couple of coats. Professionals prefer them when a premium, long lasting finish is required for a extraordinary product that wows.

3. How to Achieve the Best Metal Screen Printing Ink on Metal Substrates?

When it involves printing on metal, along with aluminum or stainless-steel, success starts with deciding on an ink especially designed for covered metals. Metallic ink shines brightest on easy, non-porous surfaces, but accurate prep and priming are vital. A clean, well-prepared floor guarantees the ink bonds nicely, delivering a long lasting, long-lasting impact that withstands each chemical and environmental exposure12.

The process commonly entails choosing a excessive-opacity screen printing ink or a specialised solvent formulation that offers advanced adhesion and resistance. For instance, professionals can also choose for a quick-drying, solvent-primarily based ink when velocity is prime in manufacturing, or use a water-primarily based, environmentally friendly ink for tasks in which chemical effect is a issue. Add more than one coats for additonal gloss and intensity—the key is to build up insurance without losing that intense, steel impact.

4. What Makes a Print on Metal Unique Compared to Other Surfaces?

Printing on steel is each an artwork and a science. The clean, non-porous floor of metals like aluminum or stainless-steel needs inks with first rate opacity, adhesion, and resistance. Unlike printing on paper or vinyl, wherein ink soaks in, metallic requires a strong coat that adheres to the surface with out peeling or fading.

This requirement means now not every ink or print technique will do; specialised display printing ink, from time to time solvent-based, is the go-to alternative for metals. These inks are specifically formulated for adhesion, gloss, and coverage. The finished product offers a mirror-like metallic impact that complements both aesthetics and sturdiness.

Printing on covered metals also expands innovative opportunities. You can add extra coats, mix inks for unique hues or consequences, and use strong point finishes for unmatched visible impact. Whether your layout requires subtle coloration or excessive reflectivity, printing on steel offers a stage of professionalism and exceptional you simply can’t get with basic substrates.

5.How to Choose the Right Ink for Your Print Product

Choosing the right ink is more than choosing a colour or effect. Start by way of thinking about the substrate: is it metallic, plastic, paper, or some thing else? Each surface has its necessities for adhesion, gloss, resistance, and coverage. For metal prints, choose a screen printing ink that boasts excessive opacity and advanced resistance to heat, chemical substances, and abrasion.

When printing on plastic or vinyl, search for ink merchandise which can be formulated for flexibility and toughness. Products like permaprint top class ink offer short drying and environmentally friendly qualities, making them ideal for projects that prioritize clean software and rapid turnaround.

Finally, recollect whether your product could be uncovered to harsh environments or heavy use. In these cases, a solvent-based totally ink with delivered sturdiness is usually recommended. The availability of a number screen printing inks lets you in shape your ink choice flawlessly to your design, production, and durability desires.

6.The Role of Coated Metals, Substrates, and Specialty Surfaces in Print

Coated metals and precise substrates like polycarbonate plastics, glass, vinyl, and mylar demand specialized interest inside the print system. Each substrate reacts in another way to ink, requiring variances in preparation and coating. For instance, a tumbler surface might also need a selected solvent or pre-coat to ensure proper adhesion of the print.

Polyester and polystyrene surfaces are popular inside the signal and label industry, demanding inks that stay vibrant and received’t crack underneath flex or exposure to mild and heat. Whether you are printing a long lasting industrial panel on aluminum or a decorative decal on plastic, know-how substrate wishes is important to achieving first-rate and professional consequences.

Modern printers and producers provide a vast choice tailored for each venture, from excessive gloss prints on chrome steel to area of expertise matte consequences on paper or vinyl.

7. Opaque Coatings and Why Coverage Is Critical in Professional Printing

Achieving an opaque print is important whilst you need bright coloration and sharp definition—in particular on dark substrates like steel. Opaque coatings in display screen printing ink provide that essential insurance, allowing lighter and metal shades to shine boldly and consistently over any history.

This is particularly critical within the production of signs and symptoms, nameplates, and high-stop client items, in which ideal opacity and insurance make sure the surface end seems easy and professionally done. Inadequate coatings can lead to washed-out prints or seen underlying cloth, undermining your mission’s exceptional and appeal.

Excellent opacity also translates to efficiency and value; fewer coats are required, overlaying a larger location with less ink and labor, and ensuring a fast and easy manufacturing cycle.

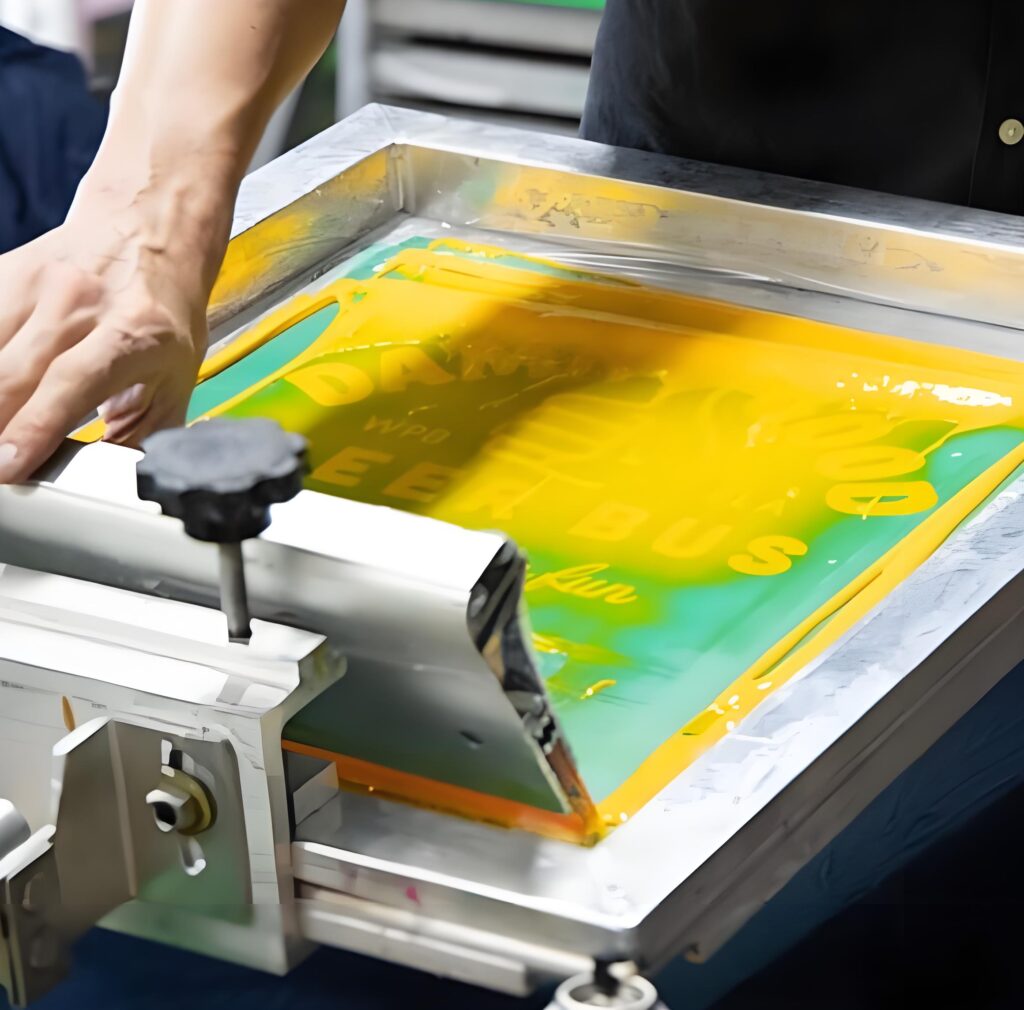

8.Application Techniques: How to Get Superior Results With Screen Printing Ink

Professional print stores depend upon specialized system and skilled method to ensure ultimate ink insurance and finish. The use of outstanding screens, squeegees, and particular pressure manipulate make sure the ink is deposited evenly, whether you’re working on metal, plastic, or paper.

Proper curing and drying are equally vital. Heat-based totally curing enhances resistance for solvent-based or warmth-cured inks, at the same time as some water-primarily based inks air-dry for a fast and environmentally friendly solution. Layering additional coats of metallic or clean ink produces richer outcomes and stronger gloss.

It’s a very good practice to test ink adhesion and coloration intensity on a sample earlier than strolling a complete manufacturing batch. Variations in substrate, climate, and ink blend can all affect the final result, so a touch training ensures a terrific, expert product whenever.

9.Addressing Durability, Resistance, and Environmental Impact

Modern display screen printing ink is engineered for sturdiness and resistance to the factors. This is a non-negotiable requirement, in particular for prints destined for outdoor, business, or excessive-put on programs. Solvent-based inks remain a gold widespread for resistance to chemicals, warmth, and abrasion, while advances in water-primarily based formulations have greatly improved their sturdiness and environmental credentials.

If you need an environmentally friendly solution, pick inks classified solvent unfastened or in particular formulated for low environmental impact. Many cutting-edge products provide super gloss, color, and coverage with decreased emissions and easy clean-up, supporting sustainability with out sacrificing first-rate.

Manufacturers now offer an outstanding variety of display printing inks that meet even the strictest environmental, durability, and resistance requirements, making it simpler than ever to choose products that deliver each expert overall performance and planet-pleasant blessings.

10.The Future: Innovations in Metallics, Ink Formulation, and Design Possibilities

The ink and print industry is usually evolving—in case your aim is a completely unique, colourful effect, preserve an eye fixed on new formulations and techniques. Recent innovations encompass extremely-rich steel ink degrees, virtual and hybrid print techniques, and uniqueness coatings presenting improved gloss and impact with better adhesion on coated metals, plastic, glass, and extra.

Recent advancements additionally cope with demands for faster production, decrease prices, and environmentally secure methods. The end result: a broader selection, more flexibility, and expanded creative freedom for every layout.

For all of us invested in advanced print excellent—whether or not it’s a one-off art project, a branded promotional product, or an business aspect—staying informed approximately the today’s ink generation ensures that your products stay both applicable and beforehand of the curve.