Mục lục

Hướng dẫn toàn diện về cách sử dụng mực Plastisol trong nhiều ngành công nghiệp khác nhau

Mực Plastisol Đây là một loại mực đặc biệt được sử dụng để in trên vải, nhựa và nhiều chất liệu khác. Nó được làm từ... Nhựa PVC Và chất dẻo (chất lỏng có dầu). Loại mực này đặc, bền và viết tốt trên các màu tối. Hãy cùng khám phá cách nó được sử dụng trong các ngành công nghiệp khác nhau!

1. Mực Plastisol là gì?

Mực Plastisol Nó không phải là chất liệu gốc nước. Nó vẫn ẩm ướt cho đến khi được làm nóng. Khi được làm nóng đến 320°F–330°F, Nó tan chảy và bám dính vào các vật liệu.

Các đặc tính chính:

- Độ mờ đụcChe phủ tốt các loại vải tối màu.

- Độ bềnChịu được giặt giũ và thời tiết.

- Hiệu quả về chi phíRẻ hơn các loại mực khác cho các đơn hàng lớn.

Vì sao mọi người yêu thích nó?:

- Màu sắc tươi sáng hơn so với mực gốc nước.

- Dễ sử dụng cho người mới bắt đầu.

- Có tác dụng trên vải cotton, polyester và nhựa.

2. Các ngành công nghiệp sử dụng mực Plastisol

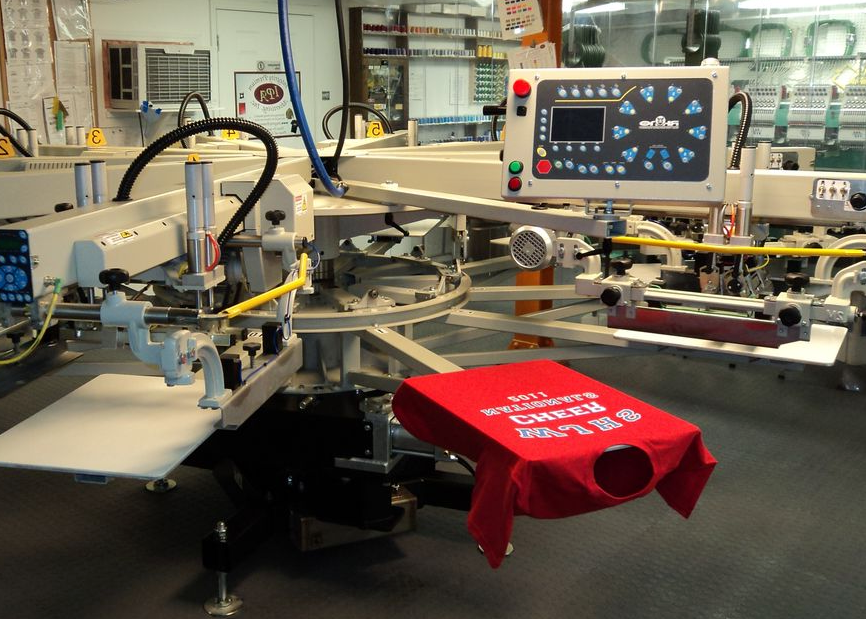

A. Ngành công nghiệp dệt may và may mặc

Mực Plastisol được sử dụng trên 75% quần áo in lụa (giống như áo phông).

Những lợi ích:

- Có thể kéo giãn mà không bị nứt.

- Vẫn sáng bóng sau đó 50+ lần giặt.

- Thích hợp cho các loại vải tối màu.

Ví dụ: Các thương hiệu như Gildan sử dụng plastisol cho 90% trong số những chiếc áo thun in hình của họ.

Thử tháchKhông thoáng khí. Để có lựa chọn thân thiện với môi trường, hãy thử... Mực in đạt chứng nhận Oeko-Tex.

Cử nhân ngành Ô tô & Sản xuất

Mực Plastisol In nhãn dán trên bảng điều khiển và dây điện ô tô.

Những lợi ích:

- Chịu nhiệtGiảm hiện tượng phai màu bằng cách: 40%.

- Bám dính vào nhựa và các vật liệu tổng hợp.

Nghiên cứu tình huống: Mực Liên Minh Sản xuất mực chống cháy cho nội thất ô tô (đáp ứng FMVSS 302 tiêu chuẩn).

C. Sản phẩm quảng cáo & Biển hiệu

Mực Plastisol In trên cốc, túi xách và biển hiệu ngoài trời.

Những lợi ích:

- Chống chịu thời tiếtĐược sử dụng trên 60% biểu ngữ PVC.

- In nhanh với truyền nhiệt.

Ví dụ: Mực truyền nhiệt của Siser tăng tốc độ sản xuất bằng cách 30%.

D. Sơn phủ công nghiệp & Thiết bị an toàn

Mực Plastisol Tăng độ bám cho sàn nhà và in trên áo phản quang.

Những lợi ích:

- Chống trượtGiảm thiểu tai nạn lao động bằng cách: 25%.

- Gặp gỡ OSHA quy tắc an toàn.

Ví dụ: Nhựa Magnolia áo khoác sàn nhà Hơn 10.000 nhà máy.

E. Các ứng dụng mới nổi

- In 3D phụ tùng ô tô (tiết kiệm) 50% (trong quá trình tạo mẫu thử).

- Áo choàng y tế kèm theo 99.9% bảo vệ khỏi vi trùng (đã được kiểm nghiệm bởi) Đại học Johns Hopkins).

3. Hướng dẫn sử dụng mực Plastisol: Hướng dẫn từng bước

A. Chuẩn bị trước khi in

- Chọn chất liệu của bạnSản phẩm này hiệu quả nhất trên chất liệu polyester hoặc cotton pha.

- Thiết lập màn hình: Sử dụng một Màn lưới 110–160.

B. Kỹ thuật in ấn

- Phân lớpThêm mực nhiều lần để tạo hiệu ứng nổi.

- Lớp nền: In màu trắng trước trên vải tối màu.

- Hiệu ứng đặc biệtTrộn vào phun hoặc kim loại chất phụ gia.

C. Các phương pháp điều trị tốt nhất

- Nhiệt độĐun nóng đến 320°F–330°F vì 60–90 giây.

- Công cụ: Sử dụng một máy sấy băng tải (giống ÔNG) hoặc máy ép nhiệt.

- Bài kiểm tra: Sử dụng một nhiệt kế Để tránh tình trạng đóng rắn chưa hoàn toàn.

D. Kiểm tra chất lượng sau khi in

- Kiểm tra độ giãnKéo vải lên để kiểm tra xem có vết nứt không.

- Thử nghiệm giặtDùng xà phòng và chất tẩy rửa để kiểm tra độ bền màu.

4. Khắc phục các sự cố thường gặp

| Vấn đề | Giải pháp |

|---|---|

| Vết nứt mực | Điều chỉnh thời gian đóng rắn; xử lý sơ bộ vải. |

| Màu sắc trông nhạt dần | Sử dụng nhiều mực hơn hoặc lưới lọc mịn hơn. |

| Mực chảy máu | Pha loãng mực; ấn nhẹ hơn. |

5. Các lựa chọn thân thiện với môi trường và an toàn

Nhựa dẻo không chứa Phthalate (giống Wilflex Epic™) là 200% phổ biến hơn kể từ năm 2020.

Mẹo an toàn:

- Theo OSHA các quy tắc xử lý.

- Tái chế 30% chất thải Với phương pháp làm sạch không dùng dung môi.

6. Xu hướng tương lai

- Mực in gốc thực vật (giống Công nghệ EcoFast™ của Dow).

- Mực lai (pha trộn plastisol + gốc nước).

- Robot giúp in ấn nhanh hơn (Kornit Kỹ thuật số).

7. Kết luận

Mực Plastisol Sản phẩm này đa năng, bền bỉ và rất phù hợp cho các dự án lớn. Hãy hợp tác với các nhà cung cấp đáng tin cậy như... Rutland hoặc Lớp phủ quốc tế Để đạt kết quả tốt nhất!

Câu hỏi thường gặp

Mực plastisol có chống thấm nước không?

Có, nếu được chữa khỏi hoàn toàn.

Tôi có thể dùng nó trên chất liệu nylon không?

Có, nhưng hãy xử lý vải trước.

Nó kéo dài trong bao lâu?

Thời hạn sử dụng từ 6 đến 12 tháng nếu bảo quản ở nơi mát mẻ.