Screen Printing Plastisol Ink is 'n veelsydige en duursame ink wat spesifiek ontwerp is vir materiaaldrukwerk. Dit is die industriestandaard vir skermdrukwerk as gevolg van sy lewendige kleure, ondeursigtigheid en gebruiksgemak. Ideaal vir druk op donker en ligte kledingstukke, Plastisol-ink skep vet, langdurige afdrukke wat veelvuldige wasgoed weerstaan sonder om te vervaag of te kraak.

- Hoë deursigtigheid: Bied uitstekende dekking, veral op donker kledingstukke.

- Lewendige kleure: Produseer helder, aanskoulike afdrukke wat uitstaan.

- Veelsydige toepassing: Geskik vir katoen, poliëster en mengsels.

- Gladde konsekwentheid: Maklik om mee te werk, verseker egalige afdrukke.

- Duursame afwerking: Weerstaan krake, afskilfering en vervaag met verloop van tyd.

- Nie-watergebaseerd: Droog nie uit in die skerm nie, wat langer werkstyd moontlik maak.

- Wye kleurreeks: Beskikbaar in standaard-, metaal-, fluoresserende en pasgemaakte kleure.

- Langlewendheid: Verseker dat afdrukke lewendig en ongeskonde bly na veelvuldige was.

- Konsekwentheid: Betroubare werkverrigting met elke druk, wat vermorsing verminder en produktiwiteit verbeter.

- Gebruiksgemak: Ideaal vir beginners sowel as professionele persone, danksy sy vergewensgesinde aard en verlengde oop tyd.

- Aanpasbaarheid: Meng goed met bymiddels om verskeie effekte te verkry, soos pof-, glans- of matafwerkings.

- Viskositeit: Medium tot hoog, afhangend van die formule.

- Flitstyd: 3-7 sekondes by 220°F (105°C).

- Uithardingstemperatuur: 320°F (160°C) vir 1-2 minute.

- Maastelling: Die beste gebruik met 110-160 maasskerms vir optimale dekking.

- Raklewe: Tot 2 jaar wanneer dit behoorlik gestoor word.

- Hitte pers: Verhard by 320°F (160°C) vir 1-2 minute. Maak seker dat die hele druk hierdie temperatuur bereik om onderverharding te vermy, wat kan lei tot uitwas.

- Vervoerband droër: Pas die spoed en temperatuur aan sodat die ink vir die aanbevole tyd 320°F (160°C) bereik. Toetsing word aangeraai om behoorlike genesing te verseker.

- Skerm skoonmaak: Gebruik 'n skermwas of minerale spiritus om oortollige ink van die skerm te verwyder. Plastisol-ink droog nie in die skerm nie maar moet dadelik skoongemaak word om opbou te voorkom.

- Gereedskap en toerusting: Maak squeegees, spatels en ander gereedskap skoon met 'n versoenbare oplosmiddelskoonmaker onmiddellik na gebruik om te verhoed dat ink hard word.

- Temperatuur: Berg in 'n koel, droë plek tussen 65-90°F (18-32°C).

- Houer: Hou die houer dig verseël wanneer dit nie gebruik word nie om kontaminasie en uitdroging te voorkom.

- Raklewe: As dit behoorlik gestoor word, sal die ink vir tot 2 jaar bruikbaar bly.

- Verpakking: Maak seker dat houers styf verseël is om lekkasies te voorkom. Gebruik sekondêre verpakking, soos plastieksakke of morsvaste houers, vir ekstra beskerming.

- Temperatuurbeheer: Vermy die blootstelling van die ink aan uiterste temperature tydens vervoer. Hoë temperature kan veroorsaak dat die ink te vloeibaar word, terwyl vries temperature tot skeiding kan lei.

- Hantering: Hanteer versigtig om gate of mors te voorkom. Vervoer regop en veilig om beweging te minimaliseer.

- Verwys na die Veiligheidsdatablad (SDS) vir gedetailleerde inligting oor veiligheid en hantering.

- Gebruik beskermende handskoene en bril wanneer ink hanteer word.

- Verseker behoorlike ventilasie tydens toediening en uitharding.

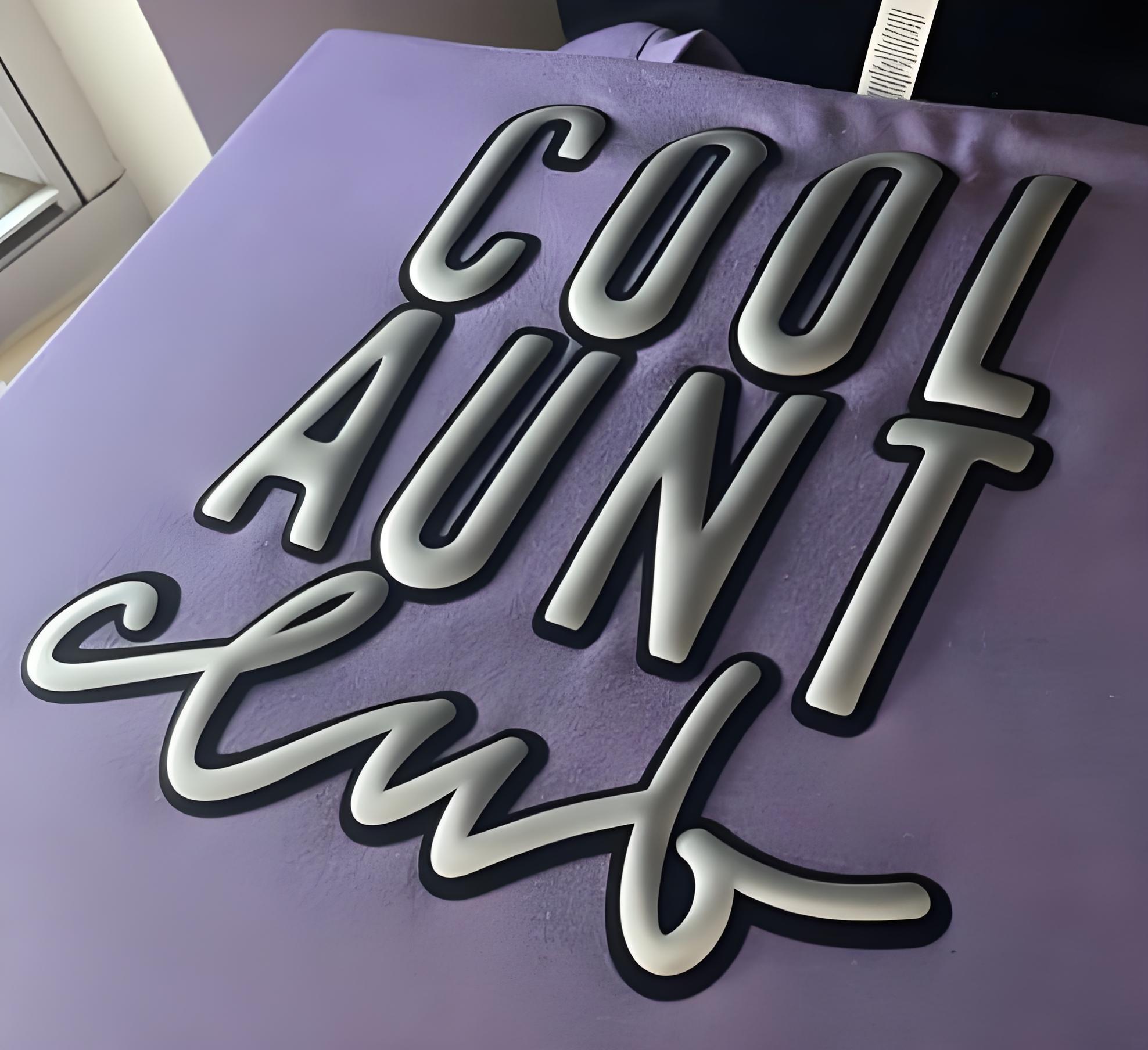

Pof-ink vir skermdruk – Hoëdigtheid 3D-effekink vir tekstiele

Reuk: Geen reuk plastisol ink, kan binne en buite gebruik word

Elastisiteit: Goeie rek vir rekstowwe

Duursaamheid: Goeie wasvastheid en kleurstabiliteit.

Duursaamheid: Hoë wasvastheid en nie maklik om te vervaag nie.

Drukbaarheid: Gladde toediening met minimale bloeding.

Hoë deursigtigheid: Almal het goeie deursigtigheid

Eienskappe: Uitstekende dekkrag

Vir professionele skermdrukkers beteken die verkryging van 'n 3D hoëdigtheid (HD) voorkoms gewoonlik duur kapillêre films en stadige produksiespoed. HONG RUI SHENG Puff Plastisol Ink verander die spel. Ons geformuleerde pof ink skermdruk oplossing laat jou toe om daardie premium, afgeronde "malvalekker"-dimensie te bereik met net een of twee drukstrepe.

Anders as generiese pof-ink wat in die droër ineenstort of soos growwe skuurpapier voel, is ons HRS-PUFF-reeks ontwerp vir cbeheerde uitbreiding stafelbaarheid. Ons gee jou die luuksheid wat jy wil hê, met die sagte, elastiese handgevoel wat jou handelsmerkkliënte vereis.

Waarom van ons verkryging?

Direkte Fabrieksprys: Geen middelman-opslag nie.

Bondelkonsekwentheid: Elke emmer het presies dieselfde blaasmiddelverhouding.

Pasgemaakte ODM: Ons kan die "pofhoogte" en "sagtheid" aanpas gebaseer op u materiaalvereistes.

Belangrike kenmerke en voordele

✅ Stabiliteit wat nie ineenstort nie

Die grootste nagmerrie met pof-ink is die "soufflé-effek" - dit styg in die droër en stort ineen wanneer dit afkoel. Ons unieke chemiese formule het 'n wyer ... hittetoleransievenster, wat verseker dat die lugborrels binne-in die ink stabiel bly, selfs al wissel die temperatuur van jou vervoerbanddroër effens.

✅ Premium “Fluweel” Tekstuur

Goedkoop pof-ink voel soos harde plastiek of polistireen. Ons formule integreer asdikwels handgemaakte elastiese hars, wat 'n oppervlak skep wat rubberagtig, glad en premium voel – perfek vir hoë-end straatklere en hoodies.

✅ Uitstekende ondeursigtigheid en dekking

Of jy nou op swart katoen of poliëstermengsels druk, ons ondeursigtigheid is van topgehalte. Vir poliëster beveel ons aan om ons grys kleurstofblokkeerder as 'n onderlaag te gebruik om kleurstofmigrasie te voorkom.

✅ Omgewingsvriendelik en voldoen aan vereistes

Ons verstaan die streng regulasies in die EU- en VSA-markte. Ons ink is:

Ftalaat-vry

Swaarmetaalvry

PVC-Hars Geoptimaliseer (Lae reuk)

Tegniese Spesifikasies (Datablad)

Om die beste resultate in u produksielyn te verseker, volg asseblief hierdie parameters wat deur ons laboratorium vasgestel is.

| Parameter | Spesifikasie | Professionele Advies |

| Tipe ink | Plastisol-gebaseerde pof | Gereed vir gebruik (of meng met pigmente) |

| Maas telling | 86 – 110 (34T – 43T) | Deurslaggewend: Hoër maas (150+) sal NIE genoeg ink neersit om te blaas nie. |

| Squeegee | 60/90/60 of 60 Durometer | Gebruik 'n sagte/medium rakel om 'n dik neerslag neer te lê. |

| Emulsie | Hoë Digtheid / Dik Laag | Gebruik 'n 2+1-bedekkingsmetode vir 'n dikker stensil (EOM). |

| Uithardingstemperatuur | 150°C – 160°C (300°F – 320°F) | Moenie oorverhit nie. Temperature bo 170°C sal ineenstorting veroorsaak. |

| Flits Temp | 100°C – 110°C | Laat dit net droog raak. Moenie die pof by die flitsstasie heeltemal uithard nie. |

Toepassingsgids: Hoe om perfek te druk

As jou oplossingsvennoot, HONG RUI SHENG wil jou sukses verseker. Volg hierdie stappe vir die perfekte 3D-effek:

Skermvoorbereiding: Skep 'n dik stensil. Hoe meer ink jy in die skerm kan hou, hoe hoër sal die sjabloon wees.

Die Onderbasisstrategie:

Vir 100% Katoen: Jy kan druk pof ink direk.

Vir rekbare materiale: Druk eers 'n deursigtige onderlaag met ons [Plastisol-ink] deursigtige basis. Dit dien as "gom" om te verhoed dat die pof kraak wanneer die hemp gerek word.

Drukwerk: Gebruik 'n skerp drukstreep. Hou jou "kontaklose" afstand effens hoër (3-5 mm) om te verseker dat die skerm skoon van die dik inkneerslag afbreek.

Genesing (Die Geheim): Laat jou bandspoed effens stadiger loop. Puff-ink benodig tyd om saggies te rys (soos brood bak). 'n Skielike hitteskok kan 'n growwe "springmielie"-oppervlak veroorsaak.

Gereelde Vrae (Gereelde Vrae)

V: Kan ek hierdie pof-ink met ander kleure meng?

Ja! Jy kan ons p menguff base met standaard plastisol-inkpigmente om persoonlike kleure te skep. Hou egter in gedagte dat die kleur ligter sal word (pastel sal word) soos die ink uitsit en die pigment versprei.

V: Waarom lyk my afdruk grof/borrelrig?

Dit is gewoonlik "Oor-uitharding" of "Hitteskok". Jou droër is te warm, wat veroorsaak dat die blaasmiddel hewig kook. Verlaag jou temperatuur met 5-10 grade en vertraag die band.

V: Kan dit op outomatiese masjiene gebruik word?

Absoluut. Ons viskositeit is aangepas vir beide handmatige en outomatiese ovaal-/karrouselmasjiene. Dit droog nie in die sif nie, wat lang produksielopies moontlik maak.

Verwante produkte

- Spesiale reeks

Metalliese Goud Skermdruk Ink