Summary: Key Takeaways for Printing Plastisol Success

- Plastisol ink: The famous ink for maximum screen print jobs—colourful, long lasting, and versatile throughout all clothing sorts.

- Screen printing with plastisol: Simple technique, forgiving for brand new screen printers, and lets in creative strong point consequences.

- Curing is vital: Invest in first-class dryers or warmness presses to make certain right therapy for max wash and peel resistance.

- Plastisol warmness transfers: Offer flexibility, perfect registration, and fast turnarounds for shirts, jerseys, and more.

- White plastisol ink: Top desire for brilliant, opaque prints; always use a professional quality to avoid dye migration.

- Mesh and deposit: Adjust display, mesh count number, and ink deposit for high-quality results with halftones, uniqueness, and widespread prints.

- Additives and uniqueness inks: Metallic, gloss, puff, and reflective outcomes maintain your work fresh and in call for.

- Prevention is fundamental: Use dye migration blockers and low-treatment inks on problematic garments.

- Soft-hand pointers: Experiment with ink additives and combining systems for softer, lighter-feeling prints.

- Continuous mastering: The display screen printing industry evolves—preserve exploring new techniques on screenprinting.Com!

How to reduce plastisol ink

Ready to up your display screen print recreation? This comprehensive manual on plastisol ink and display screen printing will display you everything you want to know—whether or not you’re a seasoned pro or just starting out. Discover how printing plastisol transforms everyday shirts into long lasting, colourful clothing, how plastisol inks for display screen printing set the same old across the printing enterprise, and the way manufacturers like screenprinting.Com gas innovation. If you’ve wondered about water based versus plastisol, curing strategies, special effects, or simply need to get the high-quality effects from every display screen, you’ll locate professional insights and palms-on pointers within the sections underneath. You can’t manage to pay for to miss the secrets and techniques to smooth finishes, gentle hand prints, and enterprise-popular ink types—examine on for everything a present day display printer wishes!

Article Outline

- What is Plastisol Ink and Why is It the Popular Ink for Screen Print?

- How Does the Screen Printing Process Work With Plastisol Ink?

- Why Is Proper Cure Essential for Plastisol Prints?

- Plastisol Heat Transfers: The Shortcut to Professional Results

- Water-Based vs. Plastisol: Which Ink Type Rules the Printing Industry?

- Additives, Special Effects, and Specialty plastisol inks

- White Plastisol Ink: The Secret to Unbeatable Opacity

- How Does Dye Migration Affect Your Screen Print?

- Getting the Right Mesh, Deposit, and Halftones

- Tips for New Screen Printers: Ensuring Longevity and Soft Hand

1. What is Plastisol Ink and Why is It the Popular Ink for Screen Print?

Plastisol ink is a completely unique kind of ink made more often than not from polyvinyl chloride (PVC) resin combined with a plasticizer. This effective method has been a sport-changer for the display printing industry, supplying excellent opacity, durability, and versatility for a wide range of print applications on clothes from jerseys to shirts. Because plastisol ink doesn’t air dry, the display printer has unlimited time to work with a display—no clogging or rushing required!

What makes plastisol ink this kind of popular ink for display printing? For starters, it promises vibrant colors and a vibrant, glossy end that in reality “pops” on material. The texture may be adjusted from smooth-hand to thick and formidable, depending on method and ink components. And due to the fact that plastisol ink essentially sits on pinnacle of the substrate, it builds up an attention grabbing, easy print with superb sturdiness—even after repeated wash cycles.

For novices and experts alike, these inks are smooth to print, require no special drying, and provide unrivaled versatility for forte results like puff, steel, or shimmer. That’s why plastisol inks for screen printing dominate the scene and are a staple on platforms like screenprinting.Com!

2.How Does the Screen Printing Process Work With Plastisol Ink?

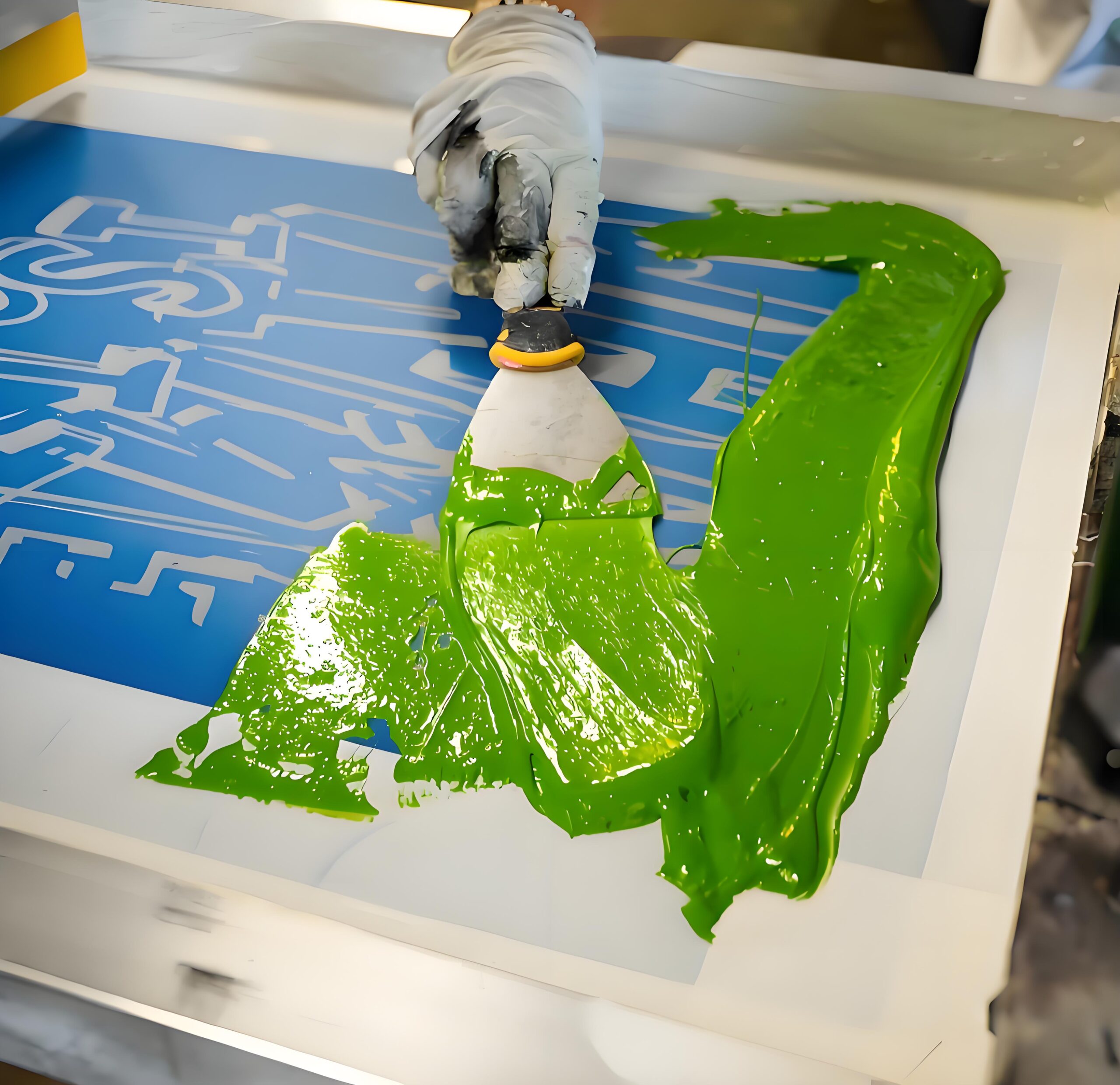

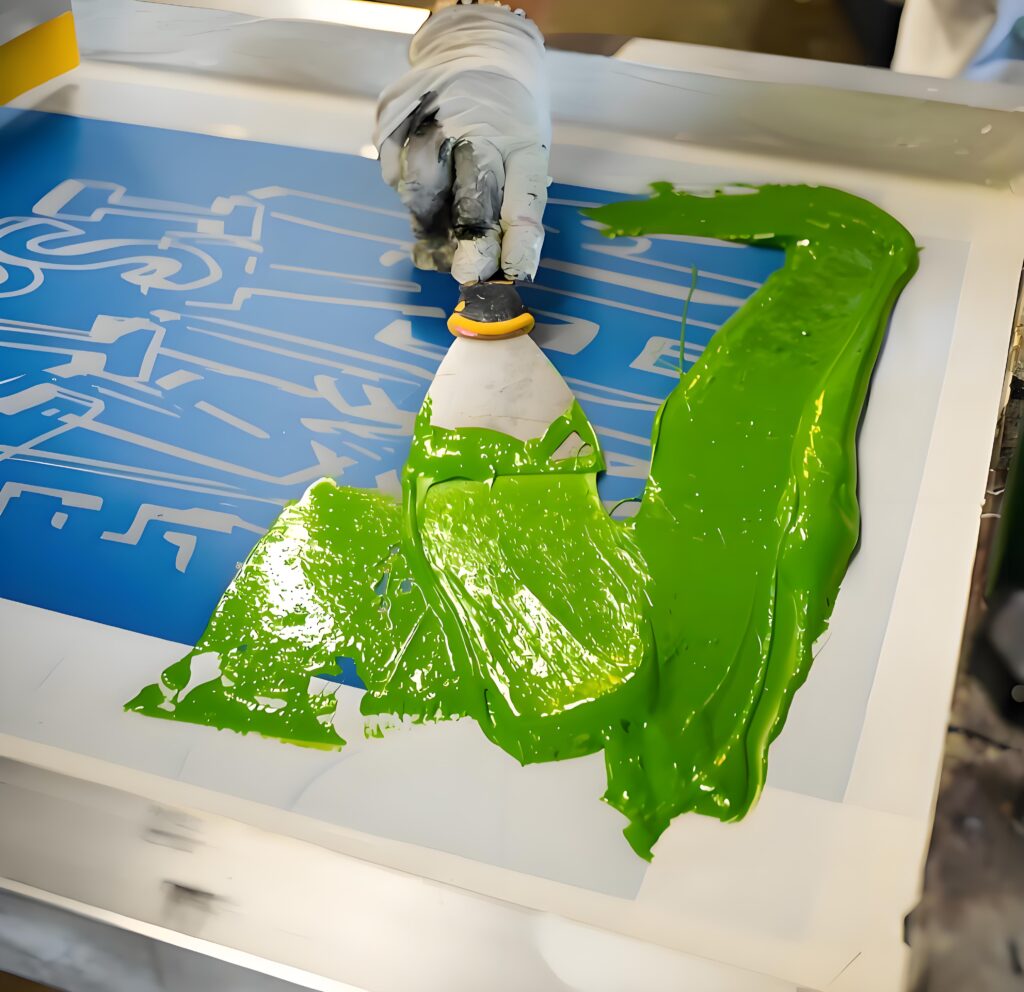

Let’s ruin down the printing technique. When you print with plastisol ink, the ink is pressed thru a mesh display, forming your layout immediately onto the fabric. This technique is the backbone of the display screen printing enterprise, making an allowance for mass production with consistent consequences on shirts, jerseys, and extra.

The magic lies within the thickness of the ink deposit and the mesh remember. A lower mesh is generally used for formidable designs and area of expertise inks (like steel or puff), whilst better mesh counts are reserved for greater designated photographs, halftones, or first-class traces. Whether you’re printing warmth transfers or going for an immediate print, expertise the interplay of mesh, deposit, and thickness is critical.

Because plastisol ink doesn’t dry till it’s cured, it gives you overall control over the printing method. No worrying approximately the ink drying on your displays! This makes multi-colour printing, moist-on-wet techniques, and even complex distinctiveness prints lots easier, even for brand spanking new display screen printers.

3. Why Is Proper Cure Essential for Plastisol Prints?

While plastisol ink is easy to print with, it could handiest attain its actual capability while well cured. Curing refers to heating the ink till it “sets,” commonly between 320-330°F (although low cure inks allow for decrease temperatures, that is top notch for heat-sensitive clothes). A conveyor dryer is often used to make certain each inch of the print reaches the preferred temperature.

Why so much fuss about the therapy? If plastisol ink doesn’t reach its proper therapy temperature, the end result may be catastrophic to your print. Poorly cured prints may additionally feel tacky, peel, crack, or even flake off after a wash. Achieving complete therapy method incredible wash durability, a vivid and vibrant end, and prints that stand the check of time.

For specialty inks–like puff, metallic, and glossy consequences–careful curing ensures you get the overall effect of components, textures, or finishes. Don’t reduce corners on this step; investing in a nice conveyor dryer or reliable warmness press will deliver professional consequences each time.

4. Plastisol Heat Transfers: The Shortcut to Professional Results

Did you already know you may use plastisol warmness transfers to print amazing snap shots that appearance and experience similar to a conventional direct-to-garment print? Printing heat transfers with plastisol ink involves printing your layout on a special switch paper, curing the ink, and then the usage of a warmness press to apply the photo in your very last substrate (garment, shirt, or different garb).

This has numerous blessings: you may put together designs in advance, integrate complicated portraits and uniqueness consequences (like metallic or shimmer), and print onto items once they’re certainly needed. Plastisol heat transfers are mainly useful for on-demand orders, athletic jerseys, or big runs with a couple of colorways or names. The nice plastisol inks for screen printing used in transfers make certain that the final print looks sharp, vibrant, and sturdy.

If you’re tight on manufacturing space, want perfect registration, or want excessive flexibility, this technique is well worth considering to your next screen print or clothing task.

5. Water-Based vs. Plastisol: Which Ink Type Rules the Printing Industry?

There’s an ongoing debate: water-primarily based ink or plastisol ink—that’s king? In phrases of the screen printing industry, plastisol is frequently desired for its smooth to print nature, dependable outcomes, and compatibility with a huge range of substrates. It’s also unrivaled for high opacity and the colourful colours you notice in many retail shirts.

Water-based inks, on the other hand, are praised for generating softer prints and being greater eco-friendly (considering the fact that they comprise fewer chemicals and are water based totally). However, they require more specific manipulate of humidity and mesh, and might dry in the screen at some point of production, making them trickier for new display screen printers.

In quick, if you want brilliant and vibrant prints with most durability and flexibility (suppose group sports wear or rapid style), plastisol remains the enterprise’s pass-to ink kind. For extremely-soft hand and greater environmentally conscious merchandise, water-primarily based inks are making inroads–however nonetheless require more expertise to grasp.

6.Additives, Special Effects, and Specialty Plastisol Inks

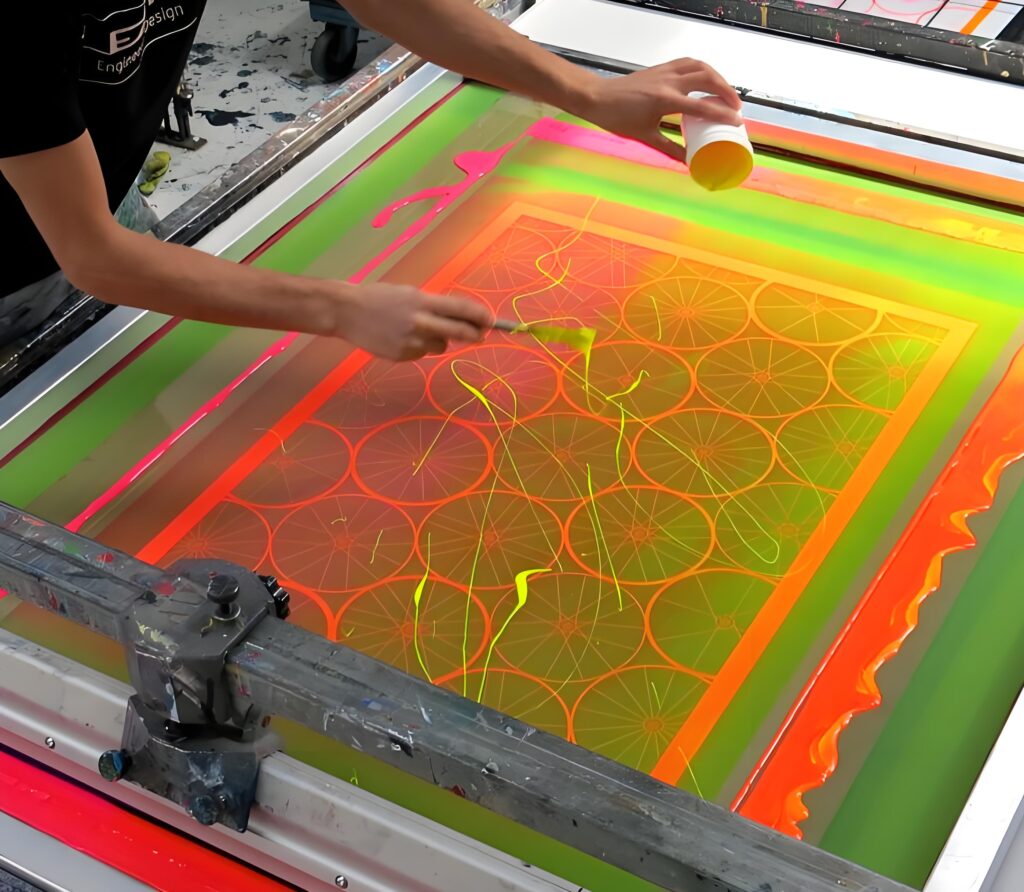

One of the best blessings of the usage of plastisol ink? Its compatibility with a wealthy style of components, making an allowance for limitless creative opportunities. Ink additives can flip your standard plastisol into a steel shimmer, deliver prints a puff (raised) effect, or even permit the ink to stretch dramatically for performance garb.

Specialty plastisol inks encompass metallic, reflective, glow-in-the-darkish, puff, or even discharge-fashion components that allow for wild, alluring consequences. By mastering the proper combos, you may produce truely custom, exquisite prints which can be the envy of the printing industry. Want a smooth print? Adding gloss-primarily based plastisol or a smooth clear overprint can help your design shine!

Remember: each additive will have an effect on the ink’s thickness, remedy necessities, and every now and then even the hand or wash residences of the print. Always take a look at your blend earlier than complete production to make sure ideal outcomes for your garment, strong point substrate, or display print needs.

7. White Plastisol Ink: The Secret to Unbeatable Opacity

Every display screen printer needs a go-to white plastisol ink of their arsenal. White ink may be notoriously problematic–however plastisol’s superb opacity, thickness, and ability to “sit down on top” of substrates make it the perfect solution, even on dark garments.

White plastisol is frequently used as an underbase to make other hues pop, specifically on darker tees and jerseys. If you’re no longer using a notable white plastisol ink, you hazard dye migration, wherein the dye from the garment “bleeds” into the ink and muddies your print. Specialized low bleed or low treatment white plastisol inks are to be had to help avoid this problem and maintain your whites simply white.

Mastering white plastisol method you’ll attain sharp, colourful prints with advanced brightness and unbeatable longevity in every wash cycle. Combine it with halftones for easy gradients or as a base for colourful distinctiveness inks to surely stand out!

8. How Does Dye Migration Affect Your Screen Print?

Dye migration is a nightmare for many display screen printers. It happens when the dye from a polyester or mixed garment migrates into the plastisol ink deposit–normally turning whites into pinks or grays. This is maximum not unusual on athletic clothing, jerseys, and performance clothes that use artificial dyes.

To save you dye migration, many printers use forte ink additives, blockers, or specially formulated low remedy plastisol inks. These allow curing at decrease temperatures, reducing the risk of liberating the garment’s dye. A right remedy, use of a terrific ink, or even a dye migration blocker base layer can save the day.

A little training is going a protracted manner. Always check new garments and inks, mainly while running with polyester. That way, you guarantee prints that stay shiny, bold, and expert.

9.Getting the Right Mesh, Deposit, and Halftones

Mesh selection is more than just numbers—it dictates how a whole lot ink is deposited at the garment and the way crisp your lines, halftones, and details seem. A better mesh depend (e.G., 230–355) is tremendous for first-class halftones, gradients, and extremely-skinny layers of plastisol ink. A lower mesh (e.G., 110–156) is used for heavy deposits, specialty inks, and bold graphics. A exchange in mesh influences the thickness and standard print first-class of your display screen print.

Halftones present a specific challenge; use softer plastisol inks and better mesh screens to keep away from filling in small dots and keep detail. Mesh tension, squeegee pressure, and ink viscosity all aspect into the nice of your very last print–that is why new display screen printers should test with small check runs before moving to production.

Don’t underestimate deposit thickness. Too plenty plastisol can leave a heavy, rubbery sense, at the same time as too little can sacrifice opacity and wash durability. Each display print is a balancing act among satisfactory, experience, and sturdiness!

10.Tips for New Screen Printers: Ensuring Longevity and Soft Hand

Just started out printing plastisol? Here are some essential tips. Always strive for a print with sturdiness—use a right therapy, keep your system, and pick out most effective great plastisol inks for display screen printing. This will make sure your prints don’t crack, flake, or peel even after infinite washes.

Want a softer print? Try reducing your deposit, experimenting with ink components, or blending systems designed for a smooth-hand feel. Modern screenprinting.Com sources have endless recipes to get a “barely there” print that competes with waterbased alternatives!

Lastly, recall to differ your method as each job is unique—take into account uniqueness inks for unique wishes, test mesh tension often, and constantly check on the exact garment you’ll be using. The extra palms-on exercise you install, the more flexible your talents turns into as a display printer.