Summary and Key Takeaways

- White plastisol ink is the industry popular for screen printing white because of its high opacity, soft hand, and forgiving cure system.

- Curing is important: constantly attain the cure temp all through the ink deposit to guarantee sturdiness and bleed resistance.

- Use a low-bleed ink and decrease remedy settings for polyester or difficult blends to save you dye migration.

- The proper combination of mesh depend, squeegee durometer, and rancid-contact improves consistency and quality.

- Ink blending systems and cautious batch manage deliver predictable, repeatable results with any type of ink.

- For tender-hand and clean prints, try meteor white or equal, manipulate ink deposit, and avoid overcuring.

- Advanced strategies like underbase printing and heat transfers expand the innovative capacity of white ink.

- Testing and perfecting your process with each new substrate or garment guarantees professional outcomes on every occasion.

- Mastering the ink, manner, and cure of white plastisol ink sets your display screen print shop apart—resulting in colourful, durable, and purchaser-captivating white prints, from black shirts to style tees!

Can you cure screen printing with white plastisol ink with a heat gun?

Are you uninterested in stupid, faded, or choppy white prints on your screen published garments? Do you marvel why your white plastisol ink once in a while healing procedures flawlessly, but different instances leaves a sticky mess or indicates dye migration? In this complete blog publish, we’ll discover everything you want to realize approximately ink selection, printing white plastisol ink, how to perfectly remedy your prints, and first-rate practices for screen printing plastisol on any garment. Whether you’re a seasoned screen printer or simply beginning out, you’ll get actionable hints, technical expertise, and a deeper understanding of what makes white ink pop and ultimate! This article is really worth analyzing if you want to supply the pleasant outcomes with white prints, avoid highly-priced errors, and offer your customers superior, long-lasting garments.

Table of Contents

1.What Makes Ink for Screen Printing Unique?

Screen printing ink isn’t just paint—it’s specifically formulated to go with the flow via a mesh screen, hold onto a garment, and therapy for sturdiness. The most popular sort of ink for display screen printing is plastisol ink. Plastisol inks are crafted from PVC debris suspended in a plasticizer, which means they set and become stable only while heated to their cure temp (temperature), commonly round 320°F (one hundred sixty°C). This makes them easy to work with, for the reason that unheated ink can be wiped off or reclaimed from the display.

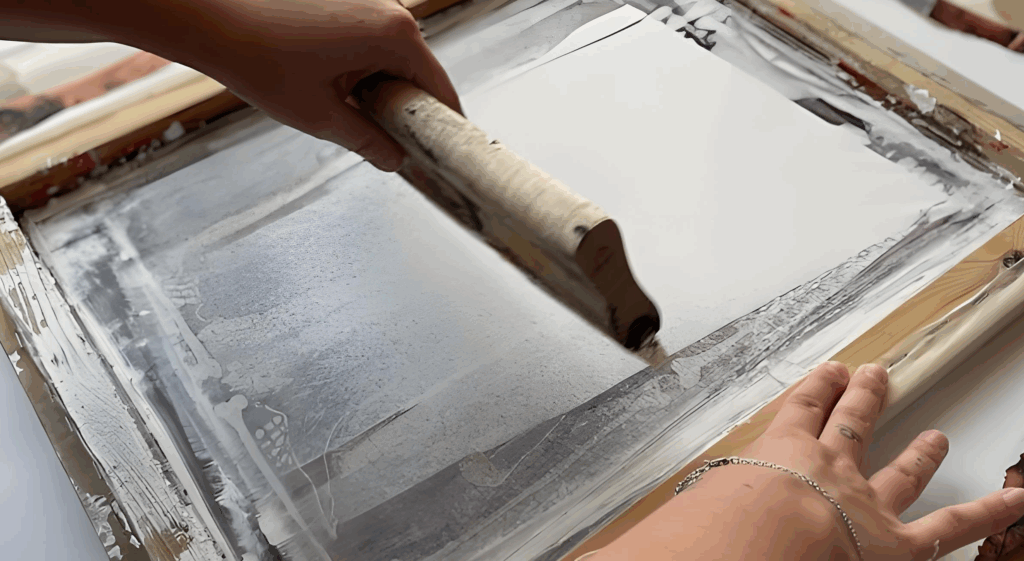

Ink deposit—the amount of ink placed at the garment—matters as it influences opacity, feel, or even how properly the print treatment options. For one-shade prints or designs where details count, the type of ink and how it interacts with the mesh display screen and squeegee (pressure, durometer, angle) all play vital roles in achieving sharp, durable outcomes .

Understanding ink for screen printing is essential if you want to achieve the fine white print or vivid colors to your garments

2.Why Is White Plastisol Ink the Standard for Printing White?

Printing white offers particular demanding situations: it calls for higher opacity than nearly any colored ink, and it have to cowl dark fabric constantly. White plastisol ink remains the enterprise trendy due to its brilliant opacity, easy drift, and potential to therapy completely for lengthy-lasting outcomes on a selection of clothes .

The great white inks are engineered to have high opacity without becoming too thick or difficult to print. In the market, different white inks serve exceptional purposes—meteor white for top class smooth-hand prints, and low bleed options for polyester and poly/cotton blends that in any other case show dye migration. Ink producers frequently label their pinnacle-acting alternatives as “low-bleed” for tough substrates like poly, or “excessive-opacity” for dark shirt jobs .

When printing white plastisol, a right ink preference is important, specifically while running with darkish garments or underbase layers

3.How to Screen Print White Plastisol Ink on Dark Garments

If you’ve ever attempted to display print white plastisol ink on a black blouse or another darkish garment, you know the risk: grey, patchy, or yellowed prints. Here’s how to get a ambitious, bright white print whenever.

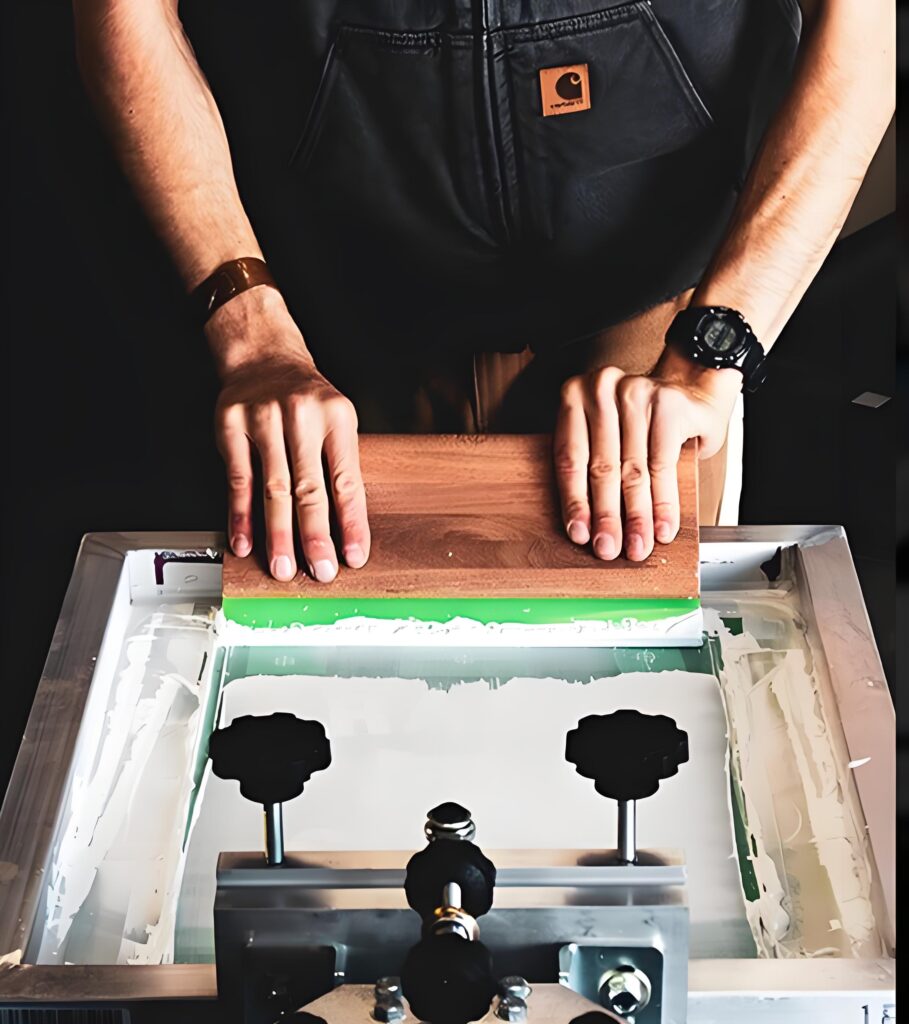

First, pick out a plastisol ink on black designed for excessive opacity and low bleed. Set up your mesh count number correctly; a decrease mesh (around 110-160) permits for a heavier ink deposit for ambitious whites. Use a squeegee with a durometer appropriate on your print—typically a medium or triple durometer for managed ink drift 235.

To prevent bleed (dye migration from polyester or poly-cotton blends), consider printing a white base (underbase) and probably using a low-bleed, low-temperature remedy ink. The right flash unit ensures your first layer gels however doesn’t remedy, allowing for clean moist-on-moist printing .

Remember, interest to ink may be used, mesh matter, and curing manner makes all of the difference for white print jobs on darkish garments

4.What is Opacity and Why Does It Matter for White Ink?

Opacity refers to how nicely an ink covers the substrate (the garment). For white ink, high opacity is essential; it prevents the blouse coloration from showing through and offers that remarkable, crisp white print customers call for .

Factors influencing opacity encompass ink formulation, mesh matter, ink deposit, and what number of passes you make with the squeegee—on occasion a 2nd, “one stroke” print builds brilliance but dangers thick, stiff prints. The fn-ink™ line and exceptional white inks frequently put it up for sale excessive opacity, however usually check on your substrate earlier than a huge print activity to assure the great effects .

If you want an extremely-shiny white print on a black shirt or maybe a colourful white print on a white shirt (for tonal consequences or textures), usually select a proper ink and take a look at for opacity rankings from your ink producers.

5.How to Cure Plastisol Ink: Temperatures, Equipment, and Tips

Curing is the chemical technique where plastisol inks solidify and bond with the material. Cure temp must be reached via the whole ink deposit, not just the surface—otherwise, you danger prints that wash out or crack. Most white plastisol ink therapies at 320°F, but many now offer decrease therapy or low treatment inks for polyester or blends .

You can therapy plastisol ink with a conveyor dryer or flash unit. Conveyor dryers allow for manage and even warmness, ensuring all prints are cured well. Flash units paintings for small runs or gelling the underbase among colorations. Always take a look at with a warmness gun or temperature strip to make certain you reach the desired 320°F without sizzling the material .

Under- or over-curing disrupts the texture (gentle hand), durability, or even bleed resistance of your white prints—don’t rush this step.

6.Preventing Bleed and Dye Migration: Secrets for Printing on Polyester

Printing white ink on polyester can be difficult because of dye migration (bleed): when the dye in the garment leaches into your white ink after curing, the once-vibrant white now looks purple or grey. To combat this, use low-bleed plastisol inks particularly formulated for polyester. These comprise chemistry that blocks dye migration, and regularly treatment at a lower temperature to avoid activating dyes inside the shirt .

Always take a look at your ink at the intended fabric, specifically if you’re running with poly or overall performance materials. Consider including a white base underbase for extra safety in opposition to bleed. Some display printers even double-hit the white ink, even though this will effect smooth-hand and sense.

7.Mesh Count, Squeegee Durometer, and Off-Contact: Setting Up for Success

Your mesh display screen selection affects ink waft—decrease mesh counts (one hundred ten-one hundred sixty) lay down more ink for ambitious whites, at the same time as better counts give smoother, finer details however danger translucent prints whilst printing white ink. The squeegee durometer (hardness) determines how lots strain is carried out; softer squeegees deposit more ink, but can smear, even as harder ones are better for crisp traces.

Off-touch—the tiny area among the screen and the garment—prevents smudging and facilitates with ink launch. Too a whole lot off-contact will make prints blurry; too little reasons sticking. Find the proper balance on your print activity, particularly with thick white ink.

8.Mixing System and Ink Mixing: Get Consistency in Your Prints

When you blend your ink, consistency is critical! Use an ink mixing system to match Pantone colors or generate custom shades for your customers. If your keep makes use of special white inks from various ink manufacturers, always log formulas and batch numbers so you can reflect a success recipes later.

Ink mixing for white plastisol ink may additionally contain including reducer to loosen float or combining a low-bleed white with a softer, high-opacity version for special print jobs.

9.Achieving a Soft-Hand Feel with White Ink on a White Shirt or Black Shirt

No consumer wishes a hard, plasticky print! To get that coveted gentle hand, use a meteor white or smooth-hand white when feasible, limit ink deposit, and dial on your mesh rely for just sufficient insurance. Soft-hand printing white ink is mainly essential for style manufacturers and athletic put on .

On a white blouse, using a smoother, decrease-viscosity white reduces buildup. On a black shirt, you may ought to compromise—extra ink for opacity, or finer mesh for softness. Find the proper stability primarily based to your print activity and customer needs.

10.Heat Transfers, Underbase, and Special Effects: Advanced White Ink Techniques

White plastisol ink isn’t only for direct prints—you may use it for heat transfers too. Print white first, remedy inks completely, then switch onto cotton garments or even poly blends with a heat press.

For forte prints, a white base (underbase) is often used earlier than laying down colored inks, in particular while printing plastisol on dark clothes. Want texture? Try a smoothing display screen after curing, or use a unique durometer squeegee for 3D results. The alternatives for creative white print results are huge!