Tabla de contenido

Una guía completa sobre el uso de tinta plastisol en diversas industrias

Tinta plastisol Es un tipo especial de tinta que se utiliza para imprimir en telas, plástico y más. Está hecho de resina de PVC y plastificantes (Líquidos aceitosos). Esta tinta es densa, duradera y funciona bien en colores oscuros. ¡Exploremos cómo se usa en diferentes industrias!

1. ¿Qué es la tinta plastisol?

Tinta plastisol No es a base de agua. Permanece húmedo hasta que se calienta. Cuando se calienta a 320°F–330°FSe derrite y se adhiere a los materiales.

Propiedades clave:

- Opacidad:Cubre fácilmente telas oscuras.

- Durabilidad:Sobrevive al lavado y al clima.

- Rentable:Más barato que otras tintas para trabajos grandes.

Por qué a la gente le encanta:

- Colores más brillantes que las tintas a base de agua.

- Fácil de usar para principiantes.

- Funciona en algodón, poliéster y plástico.

2. Industrias que utilizan tinta plastisol

A. Industria textil y de la confección

Tinta plastisol se utiliza en 75% de ropa serigrafiada (como camisetas).

Beneficios:

- Se estira sin agrietarse.

- Permanece brillante después más de 50 lavados.

- Perfecto para telas oscuras.

Ejemplo:Marcas como Gildan usar plastisol para 90% de sus camisetas gráficas.

DesafíoNo transpirable. Para opciones ecológicas, prueba Tintas con certificación Oeko-Tex.

B. Automotriz y Manufactura

Tinta plastisol Imprime etiquetas en tableros y cables de automóviles.

Beneficios:

- A prueba de calor:Reduce el desvanecimiento al 40%.

- Se adhiere a materiales plásticos y sintéticos.

Estudio de caso: Tinta de la Unión produce tinta ignífuga para interiores de automóviles (cumple con Norma FMVSS 302 normas).

C. Productos promocionales y señalización

Tinta plastisol Impresiones en tazas, bolsas y carteles para exteriores.

Beneficios:

- A prueba de la intemperie:Utilizado en 60% de pancartas de PVC.

- Rápido para imprimir con transferencias de calor.

Ejemplo: Tinta de transferencia térmica de Siser acelera la producción 30%.

D. Recubrimientos industriales y equipos de seguridad

Tinta plastisol Agrega agarre a los pisos e impresiones en chalecos de seguridad.

Beneficios:

- Antideslizante: Reduce los accidentes laborales en 25%.

- Cumple OSHA reglas de seguridad.

Ejemplo: Plásticos Magnolia recubre pisos en Más de 10.000 fábricas.

E. Usos emergentes

- Impresión 3D piezas de coche (ahorra 50% sobre creación de prototipos).

- Batas médicas con Protección contra gérmenes 99.9% (probado por Universidad Johns Hopkins).

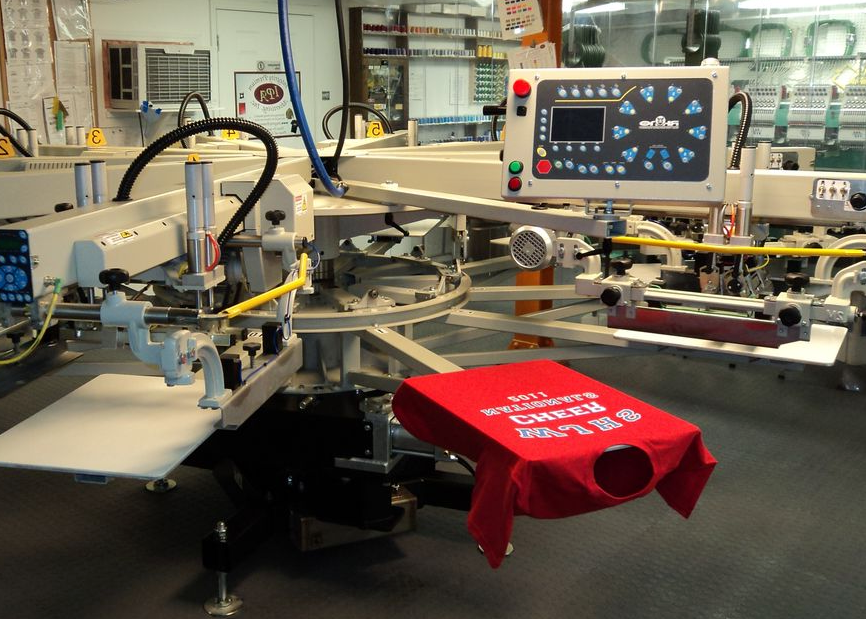

3. Cómo usar tinta plastisol: guía paso a paso

A. Preparación previa a la impresión

- Elige tu material:Funciona mejor en mezclas de poliéster o algodón.

- Configurar la pantalla:Utilice un malla de 110 a 160.

B. Técnicas de impresión

- Capas:Agregue tinta varias veces para lograr una sensación de relieve.

- Base inferior:Imprima primero en blanco sobre telas oscuras.

- Efectos especiales:Mezclar en soplo o metálico aditivos.

C. Mejores prácticas de curación

- Temperatura:Calentar a 320°F–330°F para 60–90 segundos.

- Herramientas:Utilice un secador transportador (como SEÑOR) o prensa de calor.

- Prueba:Utilice un termómetro para evitar un curado insuficiente.

D. Controles de calidad posteriores a la impresión

- Prueba de estiramiento:Tire de la tela para comprobar si tiene grietas.

- Prueba de lavado:Enjabonar y frotar para comprobar la solidez del color.

4. Solución de problemas comunes

| Problema | Solución |

|---|---|

| La tinta se agrieta | Ajustar el tiempo de curado; tratar previamente la tela. |

| Los colores se ven descoloridos | Utilice más tinta o una malla más baja. |

| La tinta sangra | Diluya la tinta y presione más suave. |

5. Opciones ecológicas y seguras

Plastisol sin ftalatos (como Wilflex Epic™) es 200% más popular desde 2020.

Consejos de seguridad:

- Seguir OSHA Reglas de manejo.

- Reciclar 30% de residuos con limpieza sin disolventes.

6. Tendencias futuras

- Tintas de origen vegetal (como EcoFast™ de Dow).

- Tintas híbridas (mezcla plastisol + base agua).

- Robots para una impresión más rápida (Kornit Digital).

7. Conclusión

Tinta plastisol Es versátil, duradero y excelente para proyectos grandes. Trabaje con proveedores confiables como Rutland o Recubrimientos internacionales ¡Para obtener los mejores resultados!

Preguntas frecuentes

¿La tinta plastisol es impermeable?

Sí, si se cura completamente.

¿Puedo usarlo sobre nailon?

Sí, pero primero trate previamente la tela.

¿Cuánto tiempo dura?

6–12 meses si se almacena en un lugar fresco.