Table des matières

Un guide complet sur l'utilisation de l'encre plastisol dans diverses industries

Encre plastisol est un type d'encre spécial utilisé pour l'impression sur tissus, plastiques, etc. Elle est fabriquée à partir de résine PVC et plastifiants (liquides huileux). Cette encre est épaisse, durable et convient parfaitement aux couleurs foncées. Découvrons son utilisation dans différents secteurs !

1. Qu'est-ce que l'encre plastisol ?

Encre plastisol n'est pas à base d'eau. Il reste humide jusqu'à ce qu'il soit chauffé. Lorsqu'il est chauffé à 320°F–330°F, il fond et adhère aux matériaux.

Propriétés clés:

- Opacité:Couvre facilement les tissus foncés.

- Durabilité:Résiste au lavage et aux intempéries.

- Rentable: Moins cher que les autres encres pour les gros travaux.

Pourquoi les gens l'aiment:

- Couleurs plus vives que les encres à base d’eau.

- Facile à utiliser pour les débutants.

- Fonctionne sur le coton, le polyester et le plastique.

2. Industries qui utilisent l'encre plastisol

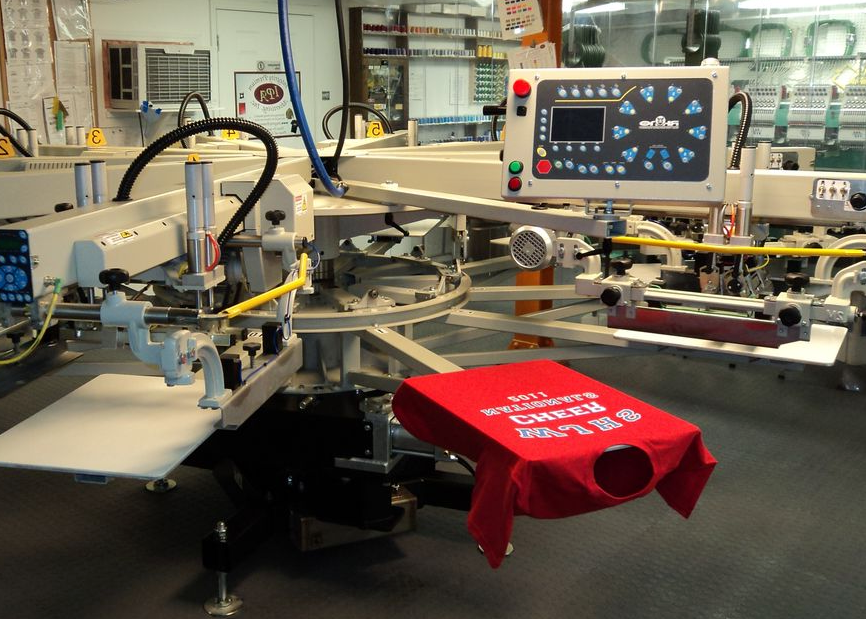

A. Industrie du textile et de l'habillement

Encre plastisol est utilisé sur 75% de vêtements sérigraphiés (comme des t-shirts).

Avantages:

- S'étire sans se fissurer.

- Reste brillant après 50+ lavages.

- Parfait pour les tissus foncés.

Exemple: Des marques comme Gildan utiliser du plastisol pour 90% de leurs t-shirts graphiques.

Défi: Non respirant. Pour des options écologiques, essayez Encres certifiées Oeko-Tex.

B. Automobile et fabrication

Encre plastisol imprime des étiquettes sur les tableaux de bord et les fils des voitures.

Avantages:

- Résistant à la chaleur: Réduit la décoloration de 40%.

- Adhère aux matières plastiques et synthétiques.

Étude de cas: Encre syndicale fabrique de l'encre ignifuge pour l'intérieur des voitures (conforme FMVSS 302 normes).

C. Produits promotionnels et signalisation

Encre plastisol impressions sur des tasses, des sacs et des panneaux extérieurs.

Avantages:

- Imperméabiliser: Utilisé sur 60% de bannières en PVC.

- Rapide à imprimer avec transferts de chaleur.

Exemple: Encre de transfert thermique de Siser accélère la production en 30%.

D. Revêtements industriels et équipements de sécurité

Encre plastisol ajoute de l'adhérence aux sols et imprime sur les gilets de sécurité.

Avantages:

- antidérapant:Réduit les accidents du travail de 25%.

- Rencontres OSHA règles de sécurité.

Exemple: Magnolia Plastics revêtements de sol en Plus de 10 000 usines.

E. Utilisations émergentes

- Impression 3D pièces détachées automobiles (économise 50% sur le prototypage).

- Blouses médicales avec Protection contre les germes 99.9% (testé par Johns Hopkins).

3. Comment utiliser l'encre Plastisol : guide étape par étape

A. Préparation avant impression

- Choisissez votre matériau:Fonctionne mieux sur les mélanges de polyester ou de coton.

- Configurer l'écran:Utilisez un Tamis de 110 à 160 mesh.

B. Techniques d'impression

- Superposition: Ajoutez de l'encre plusieurs fois pour une sensation de relief.

- Sous-couche:Imprimez d'abord le blanc sur les tissus foncés.

- Effets spéciaux: Mélanger bouffée ou métallique additifs.

C. Meilleures pratiques de séchage

- Température:Chauffer à 320°F–330°F pour 60 à 90 secondes.

- Outils:Utilisez un séchoir à convoyeur (comme M) ou presse à chaud.

- Test:Utilisez un thermomètre pour éviter un sous-durcissement.

D. Contrôles de qualité après impression

- Test d'étirement:Tirez sur le tissu pour vérifier s'il y a des fissures.

- Test de lavage: Savon et gommage pour tester la résistance des couleurs.

4. Résolution des problèmes courants

| Problème | Solution |

|---|---|

| Craquelures d'encre | Ajuster le temps de séchage ; prétraiter le tissu. |

| Les couleurs semblent fanées | Utilisez plus d'encre ou un écran à mailles plus basses. |

| L'encre coule | Diluer l’encre ; appuyer plus doucement. |

5. Options écologiques et sûres

Plastisol sans phtalate (comme Wilflex Epic™) est 200% plus populaire depuis 2020.

Conseils de sécurité:

- Suivre OSHA règles de manipulation.

- Recycler 30% de déchets avec nettoyage sans solvant.

6. Tendances futures

- Encres végétales (comme EcoFast™ de Dow).

- Encres hybrides (mélange plastisol + base eau).

- Des robots pour une impression plus rapide (Kornit Digital).

7. Conclusion

Encre plastisol Polyvalent, durable et idéal pour les grands projets, il est idéal pour les grands projets. Collaborez avec des fournisseurs de confiance comme Rutland ou Revêtements internationaux pour les meilleurs résultats !

FAQ

L'encre plastisol est-elle imperméable ?

Oui, si complètement guéri.

Puis-je l'utiliser sur du nylon ?

Oui, mais prétraitez d’abord le tissu.

Combien de temps cela dure-t-il ?

6 à 12 mois si conservé dans un endroit frais.