インドのプラスチゾルインク業界の最新動向は何ですか?

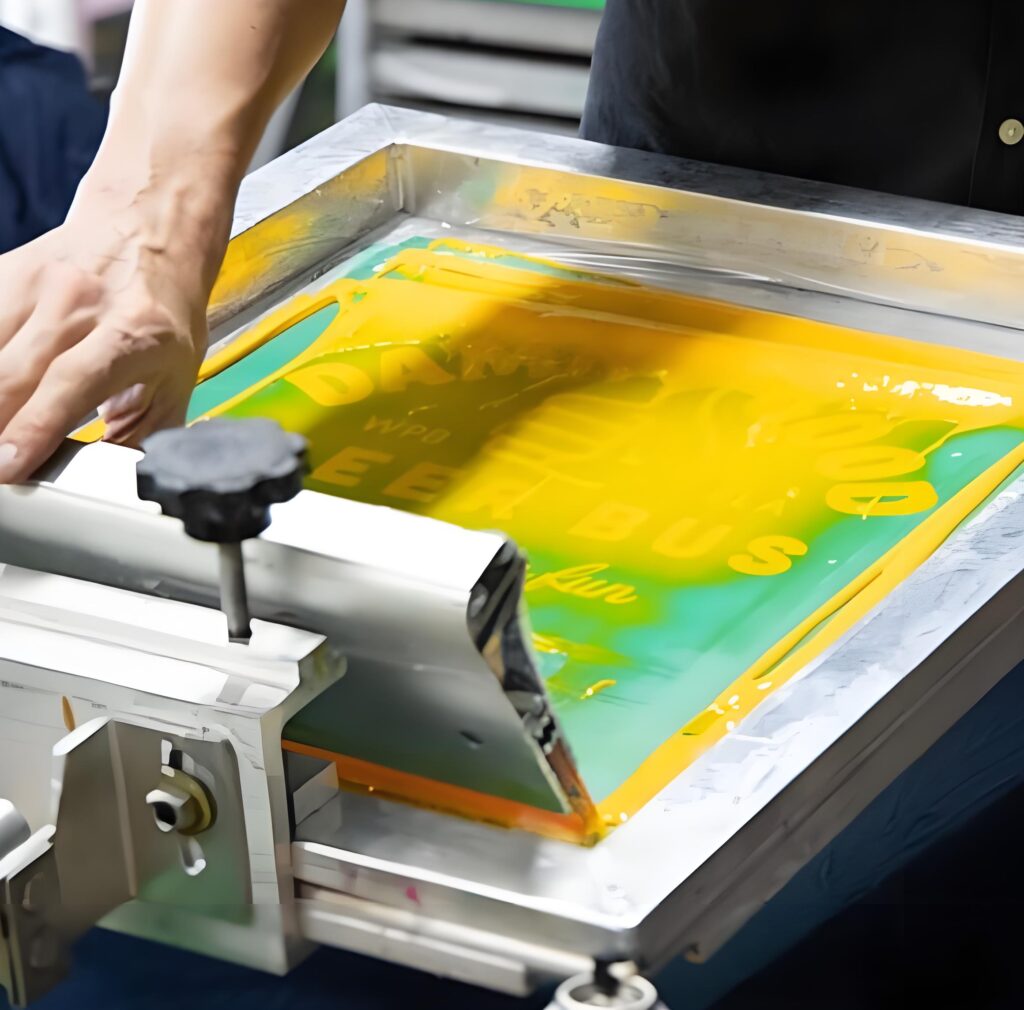

With the continuous development of the global economy and the rise of the Indian market, the Plastisol Ink industry in India exhibits tremendous growth potential. This article will delve into the latest trends in the Indian Plastisol Ink industry, analyzing market demand, technological advancements, policy support, and industry prospects, with a special focus on the application of Plastisol Ink in foil adhesive (plastisol ink in foil adhesive). I. Analysis of Market Demand for Plastisol Ink in India As one of the fastest-growing large economies globally, India’s market demand has a significant impact on the Plastisol Ink industry. According to the latest data, India’s economy grew by 7.7% in 2023, far […]