Inhaltsverzeichnis

Ein umfassender Leitfaden zur Verwendung von Plastisol-Tinte in verschiedenen Branchen

Plastisol-Tinte is a special type of ink used for printing on fabrics, plastic, and more. It is made from PVC-Harz und Weichmacher (oily liquids). This ink is thick, durable, and works well on dark colors. Let’s explore how it’s used in different industries!

1. Was ist Plastisol-Tinte?

Plastisol-Tinte is not water-based. It stays wet until heated. When heated to 320°F–330°F, it melts and sticks to materials.

Key Properties:

- Deckkraft: Covers dark fabrics easily.

- Dauerhaftigkeit: Survives washing and weather.

- Kostengünstig: Cheaper than other inks for big jobs.

Why People Love It:

- Brighter colors than water-based inks.

- Easy to use for beginners.

- Works on cotton, polyester, and plastic.

2. Industries That Use Plastisol Ink

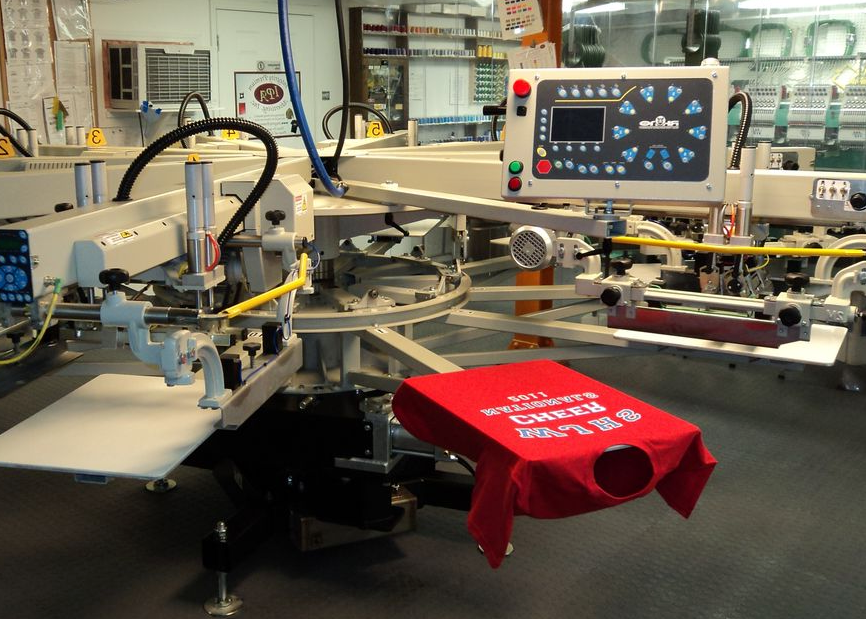

A. Textile & Apparel Industry

Plastisol-Tinte is used on 75% of screen-printed clothes (like t-shirts).

Vorteile:

- Stretches without cracking.

- Stays bright after 50+ Wäschen.

- Perfect for dark fabrics.

Beispiel: Marken wie Gildan use plastisol for 90% of their graphic tees.

Challenge: Not breathable. For eco-friendly options, try Oeko-Tex certified inks.

B. Automotive & Manufacturing

Plastisol-Tinte prints labels on car dashboards and wires.

Vorteile:

- Heat-resistant: Reduces fading by 40%.

- Sticks to plastic and synthetic materials.

Fallstudie: Union Ink makes fire-safe ink for car interiors (meets FMVSS 302 standards).

C. Promotional Products & Signage

Plastisol-Tinte prints on mugs, bags, and outdoor signs.

Vorteile:

- Wetterfest: Used on 60% of PVC banners.

- Fast to print with Wärmeübertragungen.

Beispiel: Siser’s heat-transfer ink speeds production by 30%.

D. Industrial Coatings & Safety Gear

Plastisol-Tinte adds grip to floors and prints on safety vests.

Vorteile:

- Anti-slip: Cuts workplace accidents by 25%.

- Erfüllt OSHA safety rules.

Beispiel: Magnolia Plastics coats floors in 10,000+ factories.

E. Emerging Uses

- 3D-Druck car parts (saves 50% on prototyping).

- Medical gowns with 99.9% germ protection (tested by Johns Hopkins).

3. How to Use Plastisol Ink: Step-by-Step Guide

A. Pre-Print Preparation

- Choose Your Material: Works best on polyester or cotton blends.

- Set Up the Screen: Verwenden Sie ein 110–160 mesh screen.

B. Printing Techniques

- Schichtung: Add ink multiple times for a raised feel.

- Underbase: Print white first on dark fabrics.

- Spezialeffekte: Mix in Puff oder metallisch additives.

C. Curing Best Practices

- Temperature: Heat to 320°F–330°F für 60–90 Sekunden.

- Tools: Verwenden Sie ein Durchlauftrockner (wie HERR) or heat press.

- Test: Verwenden Sie ein thermometer to avoid under-curing.

D. Post-Print Quality Checks

- Stretch Test: Pull the fabric to check for cracks.

- Wash Test: Soap and scrub to test colorfastness.

4. Fixing Common Problems

| Problem | Lösung |

|---|---|

| Ink cracks | Adjust curing time; pre-treat fabric. |

| Farben sehen verblasst aus | Use more ink or a lower mesh screen. |

| Tinte verläuft | Thin the ink; press softer. |

5. Eco-Friendly & Safe Options

Phthalatfreies Plastisol (wie Wilflex Epic™) is 200% more popular seit 2020.

Safety Tips:

- Folgen OSHA rules for handling.

- Recycle 30% of waste with solvent-free cleanup.

6. Future Trends

- Plant-based inks (wie Dow’s EcoFast™).

- Hybridtinten (mix plastisol + water-based).

- Robots for faster printing (Kornit Digital).

7. Conclusion

Plastisol-Tinte is versatile, durable, and great for big projects. Work with trusted suppliers like Rutland oder Internationale Beschichtungen for the best results!

FAQ

Ist Plastisol-Tinte wasserfest?

Yes, if cured fully.

Can I use it on nylon?

Yes, but pre-treat the fabric first.

Wie lange dauert es?

6–12 months if stored in a cool place.