Screen printing is a fascinating art form that blends creativity with precision. Central to this craft are the screen printing monitors and frames, the unsung heroes at the back of each colourful design on cloth, paper, or clothing. If you’re curious about how screen printing works or want to dive deeper into the necessities like mesh counts, aluminum frames, or the proper inks and emulsions, this newsletter is crafted only for you. Whether you’re a seasoned display screen printer or a DIY enthusiast, expertise the function of screens and frames can increase your prints from correct to beautiful. Read on to free up the secrets and techniques and resources that make your display prints pop!

Table of Contents

1.What Is a Screen in Screen Printing?

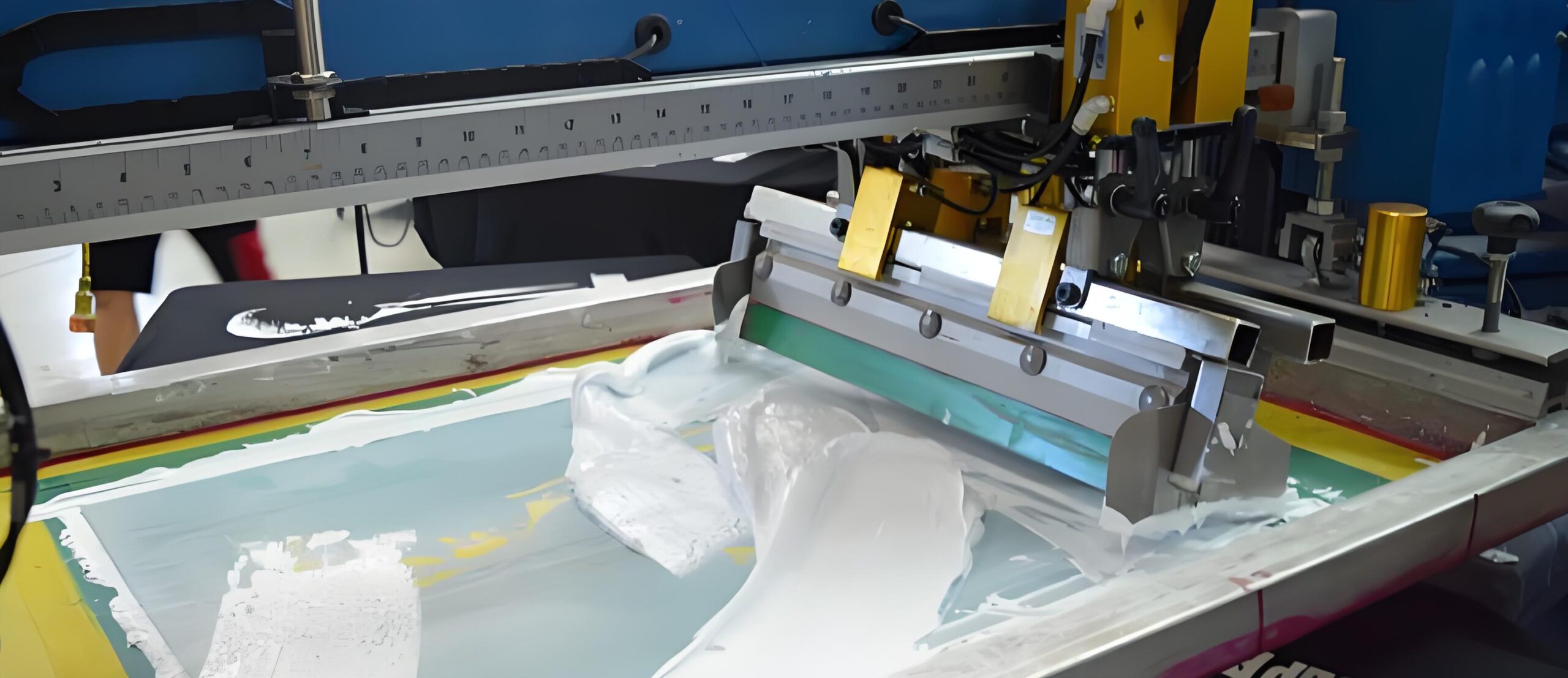

At the heart of every display print lies the display itself—an interconnected weave of threads stretched tightly over a body. This screen acts as a stencil, allowing ink to skip thru particular areas while blocking others, for this reason creating a detailed print on your preferred floor. Often called a silk screen or mesh screen, it is critical to choose the proper display screen to your display printing task to ensure accuracy and vibrancy.

The display’s cloth, referred to as display screen printing mesh, is historically crafted from polyester due to its durability and first-rate texture. It’s covered with light-sensitive emulsion, which hardens whilst uncovered to a mild supply, forming the stencil that shapes your design. This technique guarantees the regions wherein ink flows stay unblocked, yielding sharp pictures on fabric, paper, or clothing screen, silk screen, screen printing mesh, emulsion.

2.How Does Mesh Affect the Screen Print Quality?

The mesh of a screen is a important aspect that shapes the very last print’s element and texture. Mesh depend refers to the variety of threads according to inch at the screen printing mesh—the higher the mesh matter, the finer the cloth and the more detailed the print. For instance, a 110 mesh screen is desired for printing tricky designs on garments, allowing sensitive details to come thru without smudging.

Conversely, decrease mesh counts permit greater ink to pass through, appropriate for ambitious designs or thicker inks like plastisol ink. Choosing the proper mesh remember relies upon in large part in your ink kind, the substrate you are printing on, and the level of element required for your layout. Balancing mesh and ink creates prints that in reality stand out, and understanding this courting is fundamental to a success display screen printing [mesh, mesh count, 110 mesh, plastisol.

3.What Role Does Emulsion Play in Screen Printing?

Emulsion is the magical coating that turns a undeniable mesh display into a practical stencil. Typically, photographers or display screen printers practice picture emulsion at the display screen, which is then exposed to UV mild thru a film positive. This publicity hardens emulsion areas no longer blocked with the aid of the layout, washing out unexposed elements to go away behind the perfect stencil for printing.

Choosing a great emulsion enhances the durability and sharpness of your stencil, mainly whilst the use of display screen printing inks like water-primarily based or plastisol inks. A strong emulsion resists cracking and breakdown throughout the print run, making sure every garment or fabric piece incorporates a clear, steady image throughout. Proper care with emulsion remover also extends your display’s life [emulsion, photo emulsion, emulsion remover, screen printing inks, plastisol].

4.Why Are Aluminum Frames Preferred for Screen Printing Screens?

Aluminum frames have grow to be a staple within the global of display screen printing due to their light weight, durability, and resistance to warping. A nicely-stretched display screen mesh over an aluminum display screen body continues steady tension, a need to-have for wonderful prints.

Unlike timber frames, aluminum frames withstand moisture and repeated cleansing with chemicals together with emulsion remover, giving them a longer lifespan in busy display printing shops. These aluminum display screen printing frames help various mesh counts, making sure expert screen printers and hobbyists alike can customize their setup in step with task desires. The stability and precision they offer make aluminum frames an invaluable display screen printing deliver aluminum, aluminum screen, aluminum frames, screen printing frames, screen printing supplies.

5.What Is Mesh Count and How Does It Influence Your Print?

Mesh count number quantifies the thread density in your screen printing mesh and without delay impacts the look and sense of the completed print. Screens with a low mesh be counted, say a hundred and ten mesh or beneath, are greater porous—allowing greater ink to skip via. This trait is best for printing bold, thick designs the usage of plastisol ink on fabric like t-shirts or custom garb.

On the alternative hand, displays with better mesh counts produce finer and greater specific prints, perfect for precise or photographic stencil paintings. But be cautious: using a excessive mesh matter with thick inks can result in clogged displays and terrible ink transfer. Understanding extraordinary mesh counts enables display printers choose the pleasant screen for his or her favored final results [mesh count, 110 mesh, different mesh counts, plastisol ink, custom apparel].ng a high mesh count with thick inks can lead to clogged screens and poor ink transfer. Understanding different mesh counts helps screen printers choose the best screen for their desired outcome mesh count, 110 mesh, different mesh counts, plastisol ink, custom apparel.

6.How Do You Choose the Right Screen Printing Ink?

Selecting the right ink is just as crucial as choosing the perfect screen and frame. Screen printing inks come in two popular categories: plastisol and water-based inks. Plastisol ink sits on top of the garment fabric, providing vivid colors and excellent opacity—perfect for bold designs on dark textiles.

Water-based inks, in contrast, penetrate the fabric, giving a softer handfeel and a more environmentally friendly option. The screen printing mesh and emulsion you select also influence ink behavior. For instance, when using water-based inks on a screen with a very high mesh count, a suitable squeegee hard enough to push the ink through evenly is necessary to avoid patchy prints. Coupling the right ink with mesh, emulsion, and frame creates a harmonious screen printing process .

7.What Are the Essential Screen Printing Supplies and Equipment?

Beyond screens and frames, a well-stocked screen printing setup includes several critical supplies and equipment to ensure seamless production. These essentials incorporate emulsions, emulsion removers, squeegees, printing presses, and reclaiming chemicals. Each plays a specialized role in the screen printing process.

Squeegees, for instance, are used to pull ink across the mesh, forcing it through the stencil and onto your garment or substrate. The screen printing press provides alignment and stability, especially helpful for multi-color prints. Reclaim supplies like emulsion remover enable screen printers to clean and reuse screens efficiently, making them eco- and budget-friendly choices .

8.How Do Pre-Burned Screens and Custom Screens Differ?

Pre-burned screens arrive with a pre-coated emulsion ready for exposure, saving screen printers time in preparing their screens. They often appeal to DIY enthusiasts and those seeking speed in the production process. However, custom screens provide the flexibility to adjust mesh counts and emulsions to suit unique project requirements, essential for professional screen printers.

Choosing between these options depends on your experience, project scale, and desired print quality. Pre-burned screens can jumpstart beginners, while custom screens allow ultimate control over mesh, frame, and emulsion selection for seasoned printers. Both types play pivotal roles in the broad landscape of silk screen printing [pre-burned screens, custom screen, screen printing supplies and equipment.

9.What Is the Function of a Squeegee in Screen Printing?

The squeegee is the device display screen printers rely upon to push ink through the mesh screen stencil onto the fabric. It consists of a manage and a rubber blade; the hardness of this blade varies to in shape distinctive ink types and favored results.

A company squeegee is good for plastisol inks that require greater pressure to bypass via the mesh, whilst softer blades paintings well with water-based totally inks to supply even deposits with out destructive the stencil. Mastering the angle and strain even as using a squeegee can make a vast difference in the print’s sharpness and uniformity. It clearly is the printer’s brushstroke within the display screen printing system .

10.How Do You Reclaim a Screen for Reuse?

Reclaiming displays is the procedure of cleaning used screens of ink and emulsion so that they may be reused for new prints. This practice prolongs the lifestyles of your screens and frames, making it an economical and environmental should-have in display screen printing shops.

The procedure includes the usage of an emulsion remover to dissolve the hardened stencil accompanied via thorough washing to put off ink residues. After reclaiming, the monitors need to be dried and re-coated with fresh emulsion to prepare for the next publicity and print. Proper reclaiming continues aluminum frames rust-free and display mesh with superior anxiety, making sure your device is usually print-geared up .

Summary: Key Takeaways About Screen Printing Screens and Frames

- A display screen acts as a stencil lined with emulsion to manual ink go with the flow at some point of printing.

- Mesh remember determines print element; lower counts yield bolder prints, better counts finer information.

- Aluminum frames provide durability, light-weight power, and resistance to warping.

- Emulsion and emulsion remover are important for creating and reclaiming stencils.

- Squeegees stress ink via the screen, impacting print best based totally on their blade hardness.

- Choosing between pre-burned and custom monitors depends to your skill degree and challenge needs.

- Screen printing components, along with inks, emulsions, squeegees, and presses, work in concord to provide first rate prints.

- Proper reclaiming extends display screen existence and keeps printing consistency.

Understanding those additives allows screen printers—from beginners to execs—grasp the artwork of display screen printing, ensuring every print is colourful, precise, and professionally achieved. Ready to take your display printing abilities similarly? Master your monitors and frames, and watch your designs come to existence!

This comprehensive manual weaves collectively the important terminology and elements of display printing, offering you insights to enhance your craft and make knowledgeable selections about your display printing screens and frames.